This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3010937 O Ring Seal is a component designed to ensure the integrity of seals in various systems within commercial trucks. Its role is significant in maintaining the efficiency and reliability of truck operations by preventing leaks and ensuring proper system function.

Basic Concepts of O Ring Seals

An O Ring Seal is a type of gasket consisting of a toroidal (ring-shaped) piece of elastomeric material. Its primary function in mechanical systems is to create a seal between two or more parts. When compressed between flanges or in a groove, the O Ring deforms to fill the space and block the passage of fluids or gases, thus maintaining system integrity 1.

Purpose of the 3010937 O Ring Seal in Truck Operation

This Cummins part plays a specific role in the operation of commercial trucks by ensuring the sealing of various systems or components. It is commonly associated with fuel systems, where it helps maintain the integrity of fuel lines and connections, preventing leaks that could affect engine performance and safety 2.

Key Features of the 3010937 O Ring Seal

The design and material characteristics of this part contribute to its effectiveness and durability in truck applications. Made from high-quality elastomeric materials, it offers resistance to a wide range of temperatures and chemical exposures. Its precise dimensions ensure a snug fit in designated grooves, enhancing its sealing capabilities 3.

Benefits of Using the 3010937 O Ring Seal

The advantages provided by this Cummins part include improved sealing performance, which leads to enhanced system efficiency and reduced risk of leaks. Its durability ensures longevity, even under harsh operating conditions, and its resistance to various environmental factors makes it a reliable choice for commercial truck applications 4.

Installation Considerations

For optimal performance and longevity, the proper installation of this Cummins part is crucial. Guidelines suggest ensuring the sealing surfaces are clean and free of debris before installation. The O Ring should be lubricated with a compatible lubricant to facilitate insertion and reduce the risk of damage. Careful handling is advised to avoid distorting the O Ring, which could compromise its sealing ability 5.

Troubleshooting Common Issues

Common problems associated with O Ring Seals in truck applications include leaks due to wear, damage, or improper installation. Troubleshooting steps may involve inspecting the O Ring for signs of degradation or damage, ensuring it is correctly seated in its groove, and verifying that the sealing surfaces are clean and undamaged 6.

Maintenance Tips

Regular maintenance of the 3010937 O Ring Seal can prolong its service life and ensure continued reliable performance. This includes periodic inspection for signs of wear or damage, cleaning the sealing surfaces as part of routine maintenance, and replacing the O Ring as necessary to prevent leaks and maintain system integrity 7.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a strong reputation in the commercial truck industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s extensive product range and technological advancements contribute to its leadership position in the market.

Cummins Engine O Ring Seal 3010937 Compatibility

This Cummins part, manufactured by Cummins, is a critical component designed to ensure a secure seal in various engine applications. This seal is engineered to fit seamlessly with a range of Cummins engines, providing essential sealing properties that help maintain engine efficiency and performance.

ISB CM850, QSK19 CM850 MCRS

This part is compatible with the ISB CM850 and QSK19 CM850 MCRS engines. These engines are known for their robust design and high performance, often utilized in heavy-duty applications. The seal ensures that the engine’s internal components remain protected from contaminants and leaks, contributing to the longevity and reliability of these engines.

K19, K38, K50

For the K19, K38, and K50 engines, this part provides a precise fit that is essential for maintaining the integrity of the engine’s sealing systems. These engines are typically used in a variety of applications, from industrial to agricultural, and the seal’s role in preventing leaks is crucial for their operation.

N14 MECHANICAL

The N14 MECHANICAL engine benefits from this part, which is designed to fit perfectly within the engine’s sealing requirements. This ensures that the engine operates efficiently and reliably, with minimal risk of leaks or contamination.

NH/NT 855

In the NH/NT 855 engines, this part is a vital component that helps maintain the engine’s sealing integrity. This seal is engineered to provide a reliable barrier against leaks, ensuring the engine’s performance and durability.

QSK19 CM500, QSM11 CM570, QST30 CM552

This part is also compatible with the QSK19 CM500, QSM11 CM570, and QST30 CM552 engines. These engines are designed for high-performance applications, and the seal’s role in preventing leaks is critical for maintaining their efficiency and reliability.

V903

Lastly, the V903 engine is another application where this part is essential. This seal ensures that the engine’s sealing systems remain intact, protecting the engine from contaminants and leaks that could compromise its performance.

Role of Part 3010937 O Ring Seal in Engine Systems

The O Ring Seal, part number 3010937, is an essential component in ensuring the integrity and efficiency of various engine systems. Its application spans across multiple components, providing necessary sealing to prevent leaks and maintain system pressure.

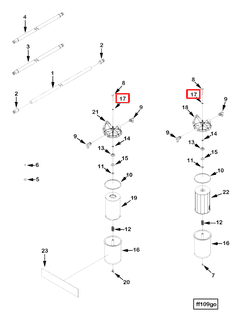

Fuel System Components

In the fuel system accessories, the O Ring Seal is utilized to create a tight seal between the fuel pump and its housing, as well as within the fuel filter head kit. This ensures that fuel is delivered without contamination or loss of pressure. Similarly, in the fuel transfer pump and fuel transfer pump kit, the seal prevents fuel leakage, which is vital for consistent fuel delivery to the engine.

Lubrication System

Within the lubricating oil pump and lubricating pump housing, the O Ring Seal plays a significant role. It ensures that oil is circulated effectively throughout the engine, reducing friction and wear on moving parts. The seal is also crucial in the lubricating oil top level assembly pump, where it maintains the required oil pressure for optimal engine performance.

Conversion and Overhaul Kits

In conversion kits such as the kit, turbo vt-50 convert, and the vt903 short block kit, the O Ring Seal is used to ensure that all new components integrate seamlessly with the existing engine system. This is particularly important in the lub pump conv where the seal helps in transitioning from an old lubrication system to a new one without any oil leaks.

Fuel and Water Separation

The seperater, fuel-water component relies on the O Ring Seal to maintain a secure barrier between the fuel and any water that may be present. This is essential for preventing water contamination in the fuel, which can lead to engine damage.

Gaskets and Housings

In components like the gasket set, upper engine gasket kit, and set lower gasket, the O Ring Seal complements the gaskets by providing additional sealing where needed. This is particularly important in the lubricating oil pump body and oil pan, where it helps in maintaining the structural integrity and pressure within the system.

Fuel Tubing and Drain

The fuel tubing and fuel drain tubing also benefit from the O Ring Seal. It ensures that fuel lines remain leak-free, which is essential for safe and efficient engine operation.

Starting and Accessories

In the accessories g.t starting system, the O Ring Seal is used to ensure that all connections are secure, facilitating a smooth start-up process without any fluid leaks.

Overall, the O Ring Seal, part number 3010937, is a versatile component that enhances the functionality and reliability of various engine systems by providing essential sealing across a wide range of applications.

Conclusion

The Cummins 3010937 O Ring Seal is a critical component in the maintenance and operation of commercial trucks and various engine systems. Its role in preventing leaks, ensuring system integrity, and contributing to engine efficiency cannot be overstated. Proper installation, regular maintenance, and understanding its compatibility with different engine models are key to maximizing the benefits of this part. Cummins’ commitment to quality and innovation is reflected in the design and performance of this essential sealing component.

-

Kasab, J., & Strzelec, A. (2020). Automotive Emissions Regulations and Exhaust Aftertreatment Systems. SAE International.

↩ -

Fijalkowski, B.T. (2011). Automotive Mechatronics Operational and Practical Issues Volume 1. Springer.

↩ -

Rajamani, R. (2005). Vehicle Dynamics and Control. Springer.

↩ -

Parikyan, T. (Ed.). (2022). Advances in Engine and Powertrain Research and Technology. Springer Nature.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual, Bulletin Number 4022092, Engine: ISF3.8 CM2220 AN.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual, Bulletin Number 4022092, Engine: ISF3.8 CM2220 AN.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual, Bulletin Number 4022092, Engine: ISF3.8 CM2220 AN.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.