This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 3015068 O-Ring Seal, manufactured by Cummins, is a component designed for use in commercial trucks. Cummins, a well-established name in the automotive industry, produces this O-Ring Seal to meet the demanding requirements of heavy-duty applications. This seal is integral to maintaining the integrity of various systems within commercial trucks, ensuring they operate efficiently and reliably.

Basic Concepts of O-Ring Seals

An O-Ring Seal is a type of gasket with a circular cross-section, designed to create a seal between two or more parts. In mechanical systems, O-Ring Seals are used to prevent the leakage of fluids and gases, ensuring that systems remain pressurized and function correctly. They operate by deforming slightly when compressed between two surfaces, creating a tight seal that can withstand pressure and resist the passage of substances 1.

Purpose of the 3015068 O-Ring Seal in Truck Operation

The 3015068 O-Ring Seal plays a specific role in the operation of commercial trucks by ensuring the integrity of seals in various systems or components. It is commonly associated with fuel systems, hydraulic systems, and engine components where maintaining a seal is crucial for performance and safety. By preventing leaks, the O-Ring Seal contributes to the efficient operation of these systems, ensuring that fluids and gases remain contained within their intended pathways 2.

Key Features of the 3015068 O-Ring Seal

The design and material characteristics of the 3015068 O-Ring Seal make it suitable for its intended applications. It is crafted from materials that offer durability and resistance to a range of chemicals and temperatures, ensuring it can withstand the harsh conditions encountered in commercial truck operations. These features allow the seal to maintain its integrity over time, providing reliable performance in critical applications 3.

Benefits of Using the 3015068 O-Ring Seal

The advantages provided by the 3015068 O-Ring Seal include improved system efficiency, longevity, and reliability in sealing applications. Its design and material properties contribute to a reduction in leaks and maintenance requirements, allowing for smoother operation of the truck’s systems. This results in enhanced performance and durability, making it a valuable component for commercial truck applications 4.

Installation Considerations

For the proper installation of the 3015068 O-Ring Seal, it is important to follow guidelines and best practices to ensure optimal performance and longevity. This includes ensuring the mating surfaces are clean and free of debris, using the correct amount of lubrication during installation, and avoiding over-tightening, which can damage the seal. Proper installation is key to achieving the seal’s full potential in preventing leaks and ensuring system integrity.

Troubleshooting Common Issues

Common problems associated with O-Ring Seals, such as leaks or failures, can often be traced back to installation issues or environmental factors. Troubleshooting steps may include inspecting the seal and mating surfaces for damage, ensuring proper installation techniques were used, and assessing the operating conditions to identify any factors that may be contributing to seal failure. Addressing these issues can help restore the seal’s effectiveness and prevent future problems.

Maintenance Tips

Regular maintenance of the 3015068 O-Ring Seal is important for ensuring its continued performance. This includes periodic inspection for signs of wear or damage, cleaning the seal and mating surfaces as needed, and replacing the seal according to manufacturer recommendations or when signs of degradation are observed. Proper maintenance can extend the life of the seal and contribute to the overall reliability of the truck’s systems.

Cummins: Manufacturer Overview

Cummins is a manufacturer with a rich history and a strong reputation in the industry for quality and innovation in automotive components. Their commitment to producing reliable and high-performance parts is evident in their wide range of products, including the 3015068 O-Ring Seal. Cummins’ focus on quality and customer satisfaction has established them as a trusted name in the commercial truck and automotive sectors.

O-Ring Seal Part 3015068 Compatibility with Cummins Engines

The O-Ring Seal part 3015068, manufactured by Cummins, is a critical component designed to ensure the integrity and efficiency of various engine systems. This seal is engineered to fit seamlessly within a range of Cummins engines, providing essential sealing capabilities to prevent leaks and maintain system pressures. Below is a detailed description of its compatibility across different engine models.

Medium Duty Engines

- ISM CM570

- ISX CM570

- QSM11 CM570

- QST30 CM552

The O-Ring Seal part 3015068 is compatible with several medium-duty engines, including the ISM CM570, ISX CM570, QSM11 CM570, and QST30 CM552. These engines are known for their robust performance and reliability, often used in various commercial applications. The seal ensures that these engines maintain optimal operational efficiency by preventing fluid leaks and maintaining system pressures.

Heavy Duty Engines

- K19

- K38

- K50

- QSK19 CM500

- QSK45 CM500

- QSK60 CM500

In the realm of heavy-duty engines, the O-Ring Seal part 3015068 is designed to fit the K19, K38, K50, QSK19 CM500, QSK45 CM500, and QSK60 CM500 models. These engines are typically used in demanding applications such as construction, mining, and heavy transportation. The seal’s compatibility with these engines ensures that they can withstand high pressures and maintain operational integrity over extended periods.

Medium Duty Engines with Mechanical and CELECT Options

- L10 MECHANICAL

- L10 CELECT

- M11 MECHANICAL

- M11 CELECT

- M11 CELECT PLUS

- N14 MECHANICAL

- N14 CELECT

- N14 CELECT PLUS

The O-Ring Seal part 3015068 is also compatible with a variety of medium-duty engines that offer both mechanical and CELECT options. These include the L10 MECHANICAL, L10 CELECT, M11 MECHANICAL, M11 CELECT, M11 CELECT PLUS, N14 MECHANICAL, N14 CELECT, and N14 CELECT PLUS. The seal’s design ensures it fits these engines perfectly, providing reliable sealing to maintain system pressures and prevent leaks.

Industrial and Power Generation Engines

- NH/NT 855

The O-Ring Seal part 3015068 is also suitable for the NH/NT 855 engine, which is often used in industrial and power generation applications. This engine requires a seal that can handle high operational demands, and the part 3015068 is engineered to meet these requirements, ensuring the engine’s longevity and efficiency.

By ensuring compatibility with a wide range of Cummins engines, the O-Ring Seal part 3015068 plays a crucial role in maintaining the performance and reliability of these engines across various applications.

Role of Part 3015068 O-Ring Seal in Engine Systems

The part 3015068 O-Ring Seal is instrumental in maintaining the integrity and efficiency of various engine components. Its application spans across multiple systems, ensuring that each part functions optimally by providing necessary sealing.

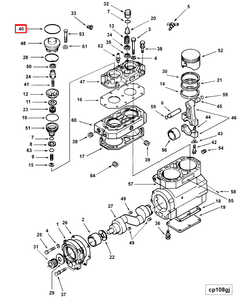

Compressor Systems

In the 2-Cylinder Compressor Cover and 2-Cylinder Compressor Head, the O-Ring Seal is used to prevent air and fluid leaks, which are vital for maintaining pressure and efficiency. Similarly, in the Air 2-Cylinder Compressor and Air Compressor, these seals ensure that the compressed air remains contained, enhancing the overall performance of the compressor.

For the Compressor Head and its associated kits such as the Compressor Head Overhaul Kit and Compressor Head Repair Kit, the O-Ring Seal plays a significant role in sealing the connections between the head and the compressor body. This is essential for preventing leaks that could reduce compressor efficiency and lead to increased wear and tear.

Accessory Drives and Gear Trains

In the Accessory Drive and Front Gear Train Accessory Drive, the O-Ring Seal is employed to ensure that lubricants remain within the system, preventing contamination and ensuring smooth operation of the drive components.

Valve Systems

The Compressor Valve (Minor) Kit, Compressor Valve Repair Kit, and Compressor Valve Replenishing Kit all utilize O-Ring Seals to maintain the integrity of the valve system. Proper sealing here is essential for efficient valve operation, which directly impacts the compressor’s ability to build and maintain pressure.

Turbocharger and Piston Systems

In the Turbocharger and Engine Piston Kit, O-Ring Seals are used to ensure that high-pressure fluids and gases are contained within their respective systems. This containment is vital for the turbocharger’s ability to boost engine performance and for the piston kit’s role in efficient combustion.

Maintenance and Service Kits

The Twin Cylinder Maintenance Kit and Twin Cylinder Service Kit incorporate O-Ring Seals to ensure that all connections within these kits are leak-free. This is particularly important during maintenance procedures, where ensuring a sealed system is crucial for accurate diagnosis and effective repairs.

Conclusion

In summary, the 3015068 O-Ring Seal is a fundamental component in various engine systems, providing the necessary seals to ensure efficient operation, prevent leaks, and maintain the overall integrity of the engine components. Its compatibility with a wide range of Cummins engines and its role in critical systems highlight its importance in maintaining the performance and reliability of commercial trucks.

-

Lakshminarayanan, P. A., & Nayak, N. S. (2011). Critical Component Wear in Heavy Duty Engines. John Wiley & Sons.

↩ -

Bosch, R. (2014). Bosch Automotive Handbook 9th Edition. Robert Bosch GmbH.

↩ -

SAE International. (2013). Composite Materials Handbook Volume 4 Metal Matrix Composites. SAE International.

↩ -

Atkins, R. D. (2009). An Introduction to Engine Testing and Development. SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.