3030808

O Ring Seal

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3030808 O Ring Seal is a component used in commercial trucks, manufactured by Cummins, a reputable manufacturer known for its quality and reliability in the automotive industry. Seals are crucial for maintaining the integrity of various systems within a vehicle, ensuring that fluids and gases remain contained within their designated pathways. This Cummins part is specifically designed to meet the demanding requirements of commercial truck operations.

Basic Concepts of O Ring Seals

An O Ring Seal is a type of gasket consisting of a circular ring of elastomer with a round cross-section. It is designed to create a seal between two or more parts. The general construction of an O Ring Seal involves a single piece of material that is looped to form a ring. Common materials used in the production of O Rings include nitrile rubber, silicone, and fluorocarbon. These materials are chosen for their ability to withstand various environmental conditions and chemical exposures. The O Ring functions by being compressed between two surfaces, creating a seal that prevents the leakage of fluids or gases 1.

Purpose of the 3030808 O Ring Seal in Truck Operations

This part is utilized in commercial trucks to ensure the integrity of specific systems or components. It is associated with systems where fluid or gas containment is necessary, such as in the engine, transmission, or hydraulic systems. By providing a reliable seal, the 3030808 O Ring Seal helps maintain the efficiency and performance of these systems 2.

Key Features of the 3030808 O Ring Seal

The 3030808 O Ring Seal is characterized by its design and material properties, which make it suitable for its intended applications. It is constructed from materials that offer durability and resistance to specific fluids encountered in truck operations. Additionally, the seal is designed to operate within a certain temperature range, ensuring it can withstand the varying conditions experienced in commercial truck environments 3.

Benefits of Using the 3030808 O Ring Seal

The use of the 3030808 O Ring Seal provides several advantages. It contributes to improved system reliability by ensuring that seals remain intact under operational conditions. This can lead to a reduction in maintenance needs, as the likelihood of leaks or failures is diminished. Furthermore, the seal plays a role in enhancing overall truck performance by maintaining the efficiency of the systems it is a part of 4.

Installation Considerations

Proper installation of the 3030808 O Ring Seal is important to ensure optimal performance and longevity. Guidelines provided by Cummins should be followed, which may include specific tools or procedures to facilitate correct installation. Attention to detail during installation can prevent issues such as improper sealing or damage to the seal.

Troubleshooting Common Issues

Common problems associated with O Ring Seals include leaks or failures. These issues can often be traced back to incorrect installation, material degradation, or exposure to incompatible fluids. Troubleshooting steps may involve inspecting the seal for signs of wear or damage, ensuring it is correctly installed, and verifying that it is compatible with the fluids and operating conditions it is exposed to.

Maintenance and Replacement

Regular inspection and maintenance of the 3030808 O Ring Seal are recommended to ensure its continued effectiveness. Signs that may indicate the need for replacement include visible wear, cracks, or a loss of sealing capability. Best practices for prolonging seal life include adhering to recommended maintenance schedules and replacing the seal as needed to prevent system failures.

Cummins: A Brief Overview

Cummins is a manufacturer with a long-standing reputation in the commercial truck industry. The company offers a wide range of products, including engines, filtration systems, and aftermarket parts. Cummins is known for its commitment to quality and innovation, providing solutions that meet the needs of commercial truck operators worldwide.

Cummins O Ring Seal 3030808 Compatibility with Various Engines

The Cummins O Ring Seal part number 3030808 is designed to ensure a secure seal in various engine applications. This seal is engineered to fit seamlessly with several engine models, enhancing their performance and longevity. Below is a detailed overview of its compatibility with the specified engines:

G855, ISV (Nissan), N14 CELECT, N14 MECHANICAL

The O Ring Seal 3030808 is compatible with the G855, ISV (Nissan), N14 CELECT, and N14 MECHANICAL engines. These engines, while differing in specific applications and configurations, share common sealing requirements that this part effectively addresses. The seal ensures that critical areas such as fuel lines, oil passages, and coolant systems maintain their integrity, preventing leaks and maintaining optimal engine performance.

NH/NT 855

The NH/NT 855 engines also benefit from the use of the Cummins O Ring Seal 3030808. This seal is designed to fit precisely in the sealing points of these engines, providing a reliable barrier against fluid leaks. Its compatibility with the NH/NT 855 ensures that the engine operates efficiently and reliably, reducing the risk of costly downtime due to maintenance issues.

QSNT14 CM876 N102

The QSNT14 CM876 N102 engine is another model that can utilize the Cummins O Ring Seal 3030808. This seal is engineered to meet the specific sealing needs of this engine, ensuring that all critical areas are properly sealed. Its use in the QSNT14 CM876 N102 engine helps maintain the engine’s performance and reliability, contributing to its overall efficiency.

By ensuring a proper fit and function in these engines, the Cummins O Ring Seal 3030808 plays a vital role in maintaining the integrity and performance of the engines it is used with.

Role of Part 3030808 O Ring Seal in Engine Systems

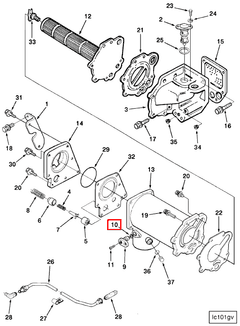

The Part 3030808 O Ring Seal is instrumental in ensuring the integrity and efficiency of various engine systems by providing reliable sealing solutions. Its application spans across multiple components, enhancing their performance and longevity.

Lubricating Oil Systems

In Lubricating Oil Filter and Cooler assemblies, the O Ring Seal prevents leaks between the filter housing and the cooler, maintaining consistent oil flow and pressure. This is vital for the effective filtration and cooling of engine oil, which in turn protects engine components from wear and tear.

The Lubricating Oil Cooler (Top Level Assembly) and Lubricating Oil Cooler Conversion Kit also benefit from the O Ring Seal by ensuring that coolant and oil pathways remain isolated, preventing contamination and ensuring optimal thermal management of the engine oil.

Oil Cooler and Maintenance Kits

Within Oil Cooler units and Oil Cooler Maintenance Kits, the O Ring Seal is used at connection points to maintain a sealed environment. This is essential for the efficient transfer of heat from the engine oil to the cooling medium, enhancing the overall cooling efficiency of the engine.

The Oil Cooler Seal Kit often includes O Ring Seals to replace worn-out seals, restoring the cooler’s sealing integrity and preventing coolant leaks, which could lead to engine overheating.

Filter and Cooler Assemblies

In Filter & Cooler Assemblies and Full Flow Oil Filters, the O Ring Seal ensures that there are no bypass flows around the filter media, guaranteeing that the oil is thoroughly filtered before re-entering the engine. This is key to maintaining clean oil, which reduces engine wear and extends component life.

Gasket and Lower Engine Gasket Sets

The Gasket Kit, Kit Gasket, Lower Engine Gasket Kit, and Lower Engine Gasket Set often incorporate O Ring Seals at critical junctions where fluid pathways intersect. These seals are essential for maintaining the integrity of the engine’s fluid systems, preventing leaks that could lead to engine damage.

Turbocharger Systems

In Turbocharger Kits and Turbocharger Plumbing, O Ring Seals are used to ensure that the oil supply lines to the turbocharger are sealed properly. This is important for maintaining the lubrication of the turbocharger’s bearings, which operate at high speeds and temperatures.

Sensing Unit Assembly

The Sensing Unit Assembly may also utilize O Ring Seals to ensure that any fluid pathways within the sensor housing are sealed, protecting sensitive electronic components from fluid ingress, which could lead to sensor malfunction.

Overall, the Part 3030808 O Ring Seal plays a significant role in maintaining the efficiency and reliability of various engine systems by providing essential sealing solutions that prevent leaks and ensure proper fluid management.

Conclusion

The Cummins 3030808 O Ring Seal is a critical component in the maintenance and operation of commercial truck engines. Its design and material properties ensure durability and resistance to the fluids and conditions encountered in truck operations. Proper installation, regular maintenance, and timely replacement of this part are essential for maintaining the efficiency and reliability of the engine systems it supports. Cummins’ commitment to quality and innovation is evident in the design and functionality of this O Ring Seal, making it a valuable asset for commercial truck operators.

-

Composite Materials Handbook Volume 4 Metal Matrix Composites, SAE International, 2013.

↩ -

Diesel Engine Care and Repair, Nigel Calder, The McGraw-Hill Companies, 2007.

↩ -

Introduction to Internal Combustion Engines, Fourth Edition, Richard Stone, Macmillan, 2012.

↩ -

The Vehicle Diesel Engine Startup Process Operational and Environmental Aspects, Pawel Drozdziel, Routledge, 2023.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.