This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3032850 O Ring Seal is a component designed to ensure the integrity of fluid systems within commercial trucks. Its purpose is to provide a reliable seal in various applications, preventing leaks and maintaining system efficiency. In the context of commercial truck maintenance and operation, this Cummins part plays a significant role by contributing to the overall reliability and performance of the vehicle.

Basic Concepts of O Ring Seals

O Ring Seals are circular elastomeric rings used to create a seal between two or more mating surfaces. They function by deforming under compression to fill the gap between the surfaces, thereby preventing the passage of fluids or gases. O Ring Seals are widely used in mechanical systems due to their simplicity, effectiveness, and versatility in various applications, including hydraulic, pneumatic, and fuel systems 1.

Role of the 3032850 O Ring Seal in Truck Operation

The Cummins 3032850 O Ring Seal is specifically designed to operate within the fluid systems of commercial trucks. It is typically located in areas where fluid transfer occurs, such as fuel injectors, hydraulic systems, and engine components. The seal’s function is to maintain the integrity of these systems by preventing leaks, ensuring that fluids are directed correctly, and contributing to the efficient operation of the truck.

Key Features of the 3032850 O Ring Seal

The design and material characteristics of the 3032850 O Ring Seal make it suitable for its intended applications. It is constructed from high-quality elastomeric materials that offer durability and resistance to a variety of fluids. Additionally, the seal is designed to withstand a wide range of operational temperatures, ensuring reliable performance under various conditions 2.

Benefits of Using the 3032850 O Ring Seal

The advantages provided by the 3032850 O Ring Seal include improved sealing efficiency, which helps to prevent leaks and maintain system pressure. Its durability contributes to the longevity of the seal, reducing the need for frequent replacements. Furthermore, the use of this seal enhances the overall reliability of the truck’s systems, leading to more consistent performance and potentially lower maintenance costs.

Troubleshooting and Maintenance Suggestions

To identify common issues related to O Ring Seals, it is important to regularly inspect the seals for signs of wear, damage, or deformation. Proper maintenance involves ensuring that the seals are correctly installed and that the mating surfaces are clean and free from debris. Additionally, following manufacturer recommendations for replacement intervals can help ensure the longevity and effectiveness of the 3032850 O Ring Seal 3.

Installation Considerations

When installing the 3032850 O Ring Seal, it is important to consider factors such as proper sizing to ensure a snug fit within the designated groove. Environmental conditions, such as temperature and exposure to chemicals, should also be taken into account to select the appropriate material for the seal. Compatibility with other components is crucial to ensure that the seal functions correctly within the system.

Common Failure Modes

Typical failure modes for O Ring Seals include compression set, where the seal loses its ability to return to its original shape after being compressed; chemical degradation, resulting from exposure to incompatible fluids or chemicals; and physical damage, such as cuts or tears. Preventive measures include selecting the correct material for the application, ensuring proper installation, and regular inspection and maintenance.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established itself as a trusted name in the commercial vehicle industry. The company’s product range includes engines, powertrains, and aftermarket parts, all designed with a commitment to quality and innovation. Cummins’ position in the industry is built on its dedication to providing reliable, efficient, and durable products that meet the needs of its customers.

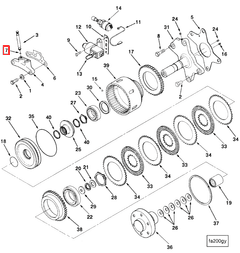

Cummins O Ring Seal 3032850 in Engine Applications

The Cummins O Ring Seal part number 3032850 is a critical component in various engine systems, ensuring the integrity of seals and preventing leaks. This part is designed to fit seamlessly into the engine architecture, providing a reliable barrier against fluid and gas leakage.

L10 MECHANICAL

In the L10 MECHANICAL engine, the O Ring Seal 3032850 plays a vital role in maintaining the engine’s operational efficiency. It is typically used in areas where a tight seal is necessary to prevent the escape of fluids or gases, such as in the fuel injection system, turbocharger, or other critical junctures. The seal’s design ensures it can withstand the high pressures and temperatures commonly encountered in engine environments, contributing to the engine’s overall durability and performance.

The precise fit and high-quality material of the O Ring Seal 3032850 are essential for the engine’s longevity and reliability. Its application in the L10 MECHANICAL engine underscores the importance of using genuine Cummins parts to maintain the engine’s integrity and performance.

Role of Part 3032850 O Ring Seal in Engine Systems

The Part 3032850 O Ring Seal is integral to maintaining the integrity and efficiency of various engine systems. Its application spans across multiple components, ensuring optimal performance and longevity.

Integration with Diagnostic Tools

In the Cylinder Diagnostic Kit and Diagnostics Instrumentation Kit, the O Ring Seal plays a significant role in preventing leaks and maintaining pressure within the diagnostic systems. This ensures accurate readings and reliable performance during engine diagnostics.

Enhancing Fan Drive Efficiency

When incorporated into the Fan Drive system, the O Ring Seal helps in sealing the moving parts, reducing friction and wear. This not only enhances the efficiency of the fan drive but also contributes to the overall cooling system’s reliability.

Sealing Engine Gaskets

In the Low Engine Gasket Kit and Lower Engine Gasket Set, the O Ring Seal is used to create a tight seal between various engine components. This prevents coolant and oil leaks, ensuring that the engine operates within safe parameters and maintains its efficiency.

Supporting Lower Engine Sets

Within the Lower Engine Set, the O Ring Seal is employed to seal critical junctions and passages. This is essential for maintaining the structural integrity of the lower engine components and ensuring that they function as intended under various operating conditions.

Precision in Single Cylinder Diagnostics

The Single Cylinder Diagnostics Needle Valve relies on the O Ring Seal to maintain precise control over fuel and air mixtures. This ensures that diagnostic tests are conducted accurately, providing valuable data for engine performance analysis and troubleshooting.

Conclusion

Overall, the Part 3032850 O Ring Seal is a fundamental component in various engine systems, contributing to their efficiency, reliability, and performance. Its role in preventing leaks, maintaining system pressure, and ensuring the longevity of engine components underscores the importance of using high-quality seals in commercial truck maintenance and operation.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.