3033248

O Ring Seal

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction to O Ring Seals

An O Ring Seal is a mechanical gasket shaped like a torus, essentially a loop or ring with a round cross-section. These seals are indispensable in both static and dynamic joints, primarily used to confine fluids within a system, prevent contaminants from entering, stop leakage, or cushion two mating surfaces. Their reliability and effectiveness make them a staple in the automotive and heavy-duty truck industries 2.

How O Ring Seals Work

O Ring Seals function by compressing between two surfaces, creating a tight seal that prevents the passage of fluids or gases. Typically made from rubber or elastomer, the seal’s material allows it to deform and conform to the surfaces it is sealing, ensuring a secure fit. The O Ring Seal’s ability to maintain its shape and seal integrity under varying pressures and temperatures makes it an essential component across various applications 1.

Purpose of Cummins Part #3033248 O Ring Seal

The Cummins Part #3033248 O Ring Seal is pivotal in the operation of commercial trucks and heavy-duty vehicles. Designed to offer a reliable seal in high-pressure environments, it ensures that fluids and gases do not leak from the system. This seal is commonly utilized in engine components, hydraulic systems, and other critical areas where maintaining a tight seal is vital for vehicle performance and safety 3.

Troubleshooting and Maintenance

Regular inspection and maintenance of O Ring Seals are crucial to ensure their effectiveness. Engineers and mechanics should routinely check for signs of wear, such as cracks, deformation, or hardening, which can compromise the seal’s integrity. If an O Ring Seal is found to be damaged, it should be replaced promptly to prevent leaks and potential system failures.

When troubleshooting issues related to O Ring Seals, identifying the root cause of the problem is essential. Common issues include improper installation, exposure to harsh chemicals or extreme temperatures, and mechanical stress. Addressing these factors can help prevent premature seal failure and extend the life of the O Ring Seal 2.

Cummins: A Leader in Engine Technology

Cummins is a renowned manufacturer of engines and related components for the commercial truck and heavy-duty vehicle industries. With a commitment to innovation and quality, Cummins has established itself as a trusted provider of reliable and high-performing engine parts. The Cummins Part #3033248 O Ring Seal exemplifies the company’s dedication to delivering durable and effective solutions for the industry 3.

Cummins O Ring Seal Part 3033248 Compatibility

The Cummins O Ring Seal part number 3033248 is a critical component designed to ensure a tight seal in various engine systems. This seal is engineered to fit seamlessly with a range of Cummins engines, providing reliable performance and durability. Here is a detailed overview of the engines with which this O Ring Seal is compatible:

B6.7 Series Engines

- B6.7 CM2350 B135B

- B6.7 CM2670 B153B

ISB/ISD Series Engines

- ISB/ISD6.7 CM2150 SN

- ISBE CM2150

- ISBE4 CM850

ISM Series Engines

- ISM CM570

- ISM CM570/870

- ISM CM876

- ISM11 CM876 SN

K Series Engines

- K19

- K38

- K50

L10 Series Engines

- L10 CELECT

- L10 GAS

- L10 MECHANICAL

M11 Series Engines

- M11 CELECT

- M11 CELECT PLUS

- M11 MECHANICAL

QSB Series Engines

- QSB7 CM2880 B117

QSK Series Engines

- QSK45 CM500

- QSK50 CM2150 K107

- QSK50 CM2150 MCRS

- QSK60 CM500

- QSK60 CM850 MCRS

- QSK60 G CM2358 K110

The O Ring Seal part 3033248 is designed to fit precisely within the specified engine models, ensuring optimal sealing performance and preventing leaks. This compatibility across various engine series highlights the versatility and robustness of the seal, making it a reliable choice for maintenance and repair across different engine types 3.

Role of Part 3033248 O Ring Seal in Engine Systems

The O Ring Seal, identified by part number 3033248, is an essential component in maintaining the integrity and efficiency of various engine systems. Its application spans across multiple components, ensuring that fluids and gases are contained within their designated pathways, thereby preventing leaks and maintaining system pressure.

Accessory Drive Gear and Support

In the accessory drive gear and its support structure, the O Ring Seal is utilized to secure fluid lines and connections. This ensures that lubricants and coolants are effectively delivered to the gear, reducing wear and enhancing longevity.

Air Transfer Tube

Within the air transfer tube system, the O Ring Seal plays a key role in sealing connections between the tube and other components. This seal is vital for maintaining the efficiency of air flow, which is crucial for combustion processes and overall engine performance.

Auxiliary Cooling System

The auxiliary cooling system relies on the O Ring Seal to maintain the integrity of coolant pathways. By sealing connections in the cylinder block and cylinder block kit, it ensures that coolant circulates effectively, preventing overheating and maintaining optimal engine temperature.

Flywheel Housing and Fuel Filter

In the flywheel housing and fuel filter assemblies, the O Ring Seal is employed to prevent leaks in fuel lines and connections. This is important for maintaining fuel pressure and ensuring a consistent supply of fuel to the engine.

Lubricating Oil Pump and Pump Kit

The lubricating oil pump and its associated kit use the O Ring Seal to ensure that oil lines remain leak-free. This is essential for delivering lubricants to moving parts, reducing friction, and prolonging the life of the engine components.

Major Repair Kit and Overhaul Kit

These comprehensive kits often include the O Ring Seal to replace worn or damaged seals during engine repairs or overhauls. This ensures that all fluid pathways are properly sealed, contributing to the overall reliability and performance of the engine post-repair.

Pump Seawater Mount and Raw Water Pump

In the pump seawater mount and raw water pump systems, the O Ring Seal is critical for sealing connections that handle seawater. This prevents contamination of the engine’s cooling system and ensures efficient heat dissipation.

Rear Gear Housing and Scavenge Pump

The rear gear housing and scavenge pump both utilize the O Ring Seal to maintain the integrity of their fluid pathways. This is important for ensuring that lubricants are effectively circulated and that any unwanted substances are properly scavenged from the engine.

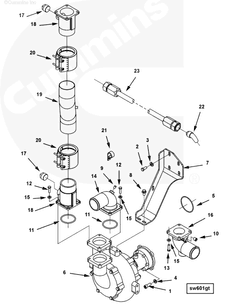

Seawater Pipe Mount and Turbocharger Arrangement

In the seawater pipe mount and turbocharger arrangement, the O Ring Seal is used to seal connections that are exposed to high pressures and temperatures. This ensures that the systems operate efficiently and reliably under demanding conditions.

Water Pump Kit

Finally, in the water pump kit, the O Ring Seal is essential for sealing the pump’s connections to the engine’s cooling system. This ensures that coolant is effectively circulated, maintaining engine temperature and preventing overheating 3.

Conclusion

Understanding the Cummins Part #3033248 O Ring Seal is crucial for maintaining the reliability and performance of commercial trucks and heavy-duty vehicles. This part plays a vital role in sealing various engine systems, preventing leaks, and ensuring efficient operation. Regular maintenance and prompt replacement of worn seals are essential practices for professionals in the industry to uphold vehicle performance and safety standards.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.