This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3043995 O-Ring Seal is a critical component designed to ensure the integrity of seals within commercial truck systems. Its role is significant in maintaining the efficiency and reliability of these vehicles. Understanding its purpose and function is key to appreciating its importance in the operation of commercial trucks.

Basic Concepts of O-Ring Seals

An O-Ring Seal is a toroidal (ring-shaped) elastomer with a circular cross-section, used to create a seal between two or more parts. It operates by being compressed within a groove, forming a barrier that prevents the leakage of fluids or gases. O-Ring Seals are widely utilized in mechanical systems for their simplicity, effectiveness, and versatility in creating seals in various applications 1.

Purpose of the Cummins 3043995 O-Ring Seal

The Cummins 3043995 O-Ring Seal is specifically designed to play a role in the sealing mechanisms of commercial trucks. It is typically associated with systems or components where fluid or gas containment is necessary to maintain system efficiency and prevent leaks. This includes applications within the engine, transmission, and other critical systems where seals are paramount.

Key Features

This Cummins part is characterized by its material composition, which is selected for durability and resistance to the harsh conditions encountered in heavy-duty applications. Its design is tailored to ensure a snug fit within the designated grooves, providing a reliable seal. These features make it well-suited for the demanding environments of commercial truck operations.

Benefits

Utilizing the Cummins 3043995 O-Ring Seal offers several advantages, including enhanced system efficiency through reliable sealing, increased longevity due to its durable construction, and improved reliability in demanding environments. These benefits contribute to the overall performance and maintenance of commercial trucks.

Installation and Usage

Proper installation of the Cummins 3043995 O-Ring Seal involves ensuring it is correctly seated within the designated groove without damage. Best practices include cleaning the groove before installation and avoiding over-lubrication, which can lead to seal extrusion. It is commonly used in applications where a secure seal is required to maintain system integrity 2.

Troubleshooting and Maintenance

Common issues with O-Ring Seals can include leaks due to wear, improper installation, or environmental factors. Regular maintenance checks can help identify signs of wear or failure, such as fluid leaks or reduced system performance, indicating the need for replacement. Proper handling and storage of O-Ring Seals can also contribute to their longevity.

Common Failure Modes

O-Ring Seals may fail due to material degradation over time, improper installation leading to seal extrusion, or exposure to incompatible fluids or extreme temperatures. Understanding these failure modes can aid in troubleshooting and preventing seal-related issues in commercial truck systems.

Replacement and Upgrades

When replacing the Cummins 3043995 O-Ring Seal, it is important to ensure the new seal is compatible with the application and meets the required specifications. Considerations for upgrades may include seals with enhanced material properties for improved performance in specific environments or applications.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a strong reputation in the commercial truck industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction, providing reliable and efficient power solutions for various applications.

O-Ring Seal 3043995 Compatibility with Cummins Engines

The O-Ring Seal part number 3043995, manufactured by Cummins, is a critical component designed to ensure the integrity and efficiency of various engine systems. This seal is engineered to fit seamlessly into multiple Cummins engine models, providing a reliable barrier against leaks and maintaining system pressure. Here is a detailed overview of the engines with which this O-Ring Seal is compatible:

6-Cylinder Engines

- 6B5.9

- 6C8.3

- B5.9 G

- C8.3 G

- QSB5.9 44 CM550

These engines, primarily used in heavy-duty applications, benefit from the O-Ring Seal 3043995 in maintaining the integrity of their hydraulic and fuel systems.

8-Cylinder Engines

- 4B3.9

- ISB CM550

- QSC8.3 CM554

These engines, often found in larger vehicles and industrial machinery, rely on the O-Ring Seal 3043995 to prevent leaks in critical areas, ensuring optimal performance and longevity.

12-Cylinder Engines

- ISX CM570

- ISM CM570

- ISC CM554

- ISL CM554

High-power engines such as these, used in the most demanding applications, require the precision and reliability of the O-Ring Seal 3043995 to maintain system integrity under extreme conditions.

6-Cylinder Gas Engines

- C GAS PLUS CM556

This engine, designed for gas applications, utilizes the O-Ring Seal 3043995 to ensure efficient sealing in gas systems, contributing to the engine’s overall performance and efficiency.

10-Cylinder Engines

- L10 CELECT

- L10 GAS

- L10 MECHANICAL

These engines, often used in specialized applications, depend on the O-Ring Seal 3043995 to maintain system pressure and prevent leaks, ensuring reliable operation.

12-Cylinder Diesel Engines

- M11 CELECT

- M11 CELECT PLUS

- M11 MECHANICAL

These engines, known for their power and efficiency, benefit from the O-Ring Seal 3043995 in maintaining the integrity of their fuel and hydraulic systems.

14-Cylinder Diesel Engines

- N14 CELECT

- N14 CELECT PLUS

- N14 MECHANICAL

These high-performance engines, used in the most demanding applications, rely on the O-Ring Seal 3043995 to ensure system integrity and prevent leaks.

Industrial Engines

- K19

- K38

- NH/NT 855

These engines, often used in industrial and marine applications, depend on the O-Ring Seal 3043995 to maintain system pressure and prevent leaks, ensuring reliable operation in harsh environments.

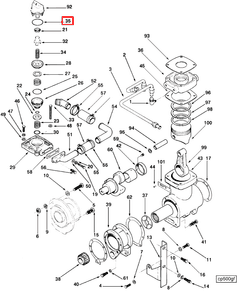

Role of Part 3043995 O-Ring Seal in Engine Systems

The part 3043995 O-Ring Seal is integral to the efficient operation and maintenance of various engine components. Its application spans across multiple systems, ensuring optimal performance and longevity of the engine.

Accessory Drive

In the accessory drive system, the O-Ring Seal plays a significant role in maintaining the integrity of connections and preventing leaks. It ensures that the drive components operate smoothly without any fluid loss, which is essential for the consistent performance of accessories like alternators and water pumps.

Air Compressor Systems

For air compressors, the O-Ring Seal is used in several critical areas. In the Air Compressor itself, it helps in sealing the compressor housing, ensuring that compressed air does not escape, thus maintaining pressure levels.

In the Air Compressor Conversion Kit and Air Compressor Drive, the seal is employed to secure connections between various components, facilitating efficient air compression and delivery.

Assembly and QE Unloader Systems

Within the Assembly and QE Unloader systems, the O-Ring Seal is vital for sealing connections in the unloader mechanism. This ensures that the unloader operates correctly, regulating the compressor’s load and protecting it from overloading.

Compressor Head and Valve Systems

In the Compressor Head Replenishing Kit, Compressor Head Uprate Kit, and Compressor Super Uprate Kit, the O-Ring Seal is used to ensure that the head components are tightly sealed. This prevents any air leaks that could reduce compressor efficiency.

For the Compressor Valve (Minor) Kit and Compressor Valve Body Assembly, the seal is crucial in maintaining the integrity of valve operations, ensuring that valves open and close properly without any air leakage.

Cylinder and Overhaul Kits

In the Compressor 1 Cylinder Air system and various Engine Overhaul Kits, the O-Ring Seal is used to secure cylinder components, ensuring that air remains contained within the cylinders during compression and expansion cycles.

Specific Head Assemblies

The O-Ring Seal is also employed in QE/C, Head Assy, QE/M, Head Assy, and QE/STD, Head Assy kits to ensure that head assemblies are properly sealed, preventing any fluid or air leaks that could affect engine performance.

Repair and Maintenance Kits

In Kit, CPRS Repair, Kit, PDC, Kit, SI Cyl E-Type Maint, Overhaul Kit, and Repair Kit Valve, the O-Ring Seal is essential for repairing and maintaining various engine components. It ensures that all repaired parts are securely sealed, contributing to the overall reliability of the engine.

Gasket Sets and Conversion Kits

Finally, in Set Gasket and Unloader Conversion Kit, the O-Ring Seal is used to replace or upgrade gaskets and seals, ensuring that all connections remain tight and leak-free.

Overall, the part 3043995 O-Ring Seal is a fundamental component in maintaining the efficiency and reliability of various engine systems, playing a key role in sealing connections and preventing leaks.

Conclusion

The Cummins 3043995 O-Ring Seal is a vital component in the maintenance and operation of commercial truck systems. Its role in ensuring the integrity of seals across various engine components underscores its importance in maintaining system efficiency and reliability. Proper installation, regular maintenance, and understanding common failure modes are essential for maximizing the benefits of this part in demanding environments.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.