This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3045877 O Ring Seal is a component designed to ensure the integrity of seals within commercial truck engines. Its purpose is to prevent leaks and maintain system efficiency. The significance of this seal lies in its ability to contribute to the reliable operation of trucks, which are often subjected to demanding conditions.

Basic Concepts of O Ring Seals

An O Ring Seal is a toroidal (ring-shaped) elastomer with a circular cross-section. It functions by creating a seal between two or more mating surfaces, typically in a gland. When compressed, the O Ring deforms to fill the space between the surfaces, thereby preventing the passage of fluids or gases. This mechanism is fundamental in various mechanical systems to ensure the containment of substances and the prevention of leaks 1.

Role of the 3045877 O Ring Seal in Truck Operation

The Cummins 3045877 O Ring Seal plays a specific role in the operation of commercial trucks by ensuring the integrity of seals within the engine or other systems. It is typically placed in areas where fluid or gas containment is necessary to prevent leaks that could lead to system inefficiency or failure. Its function is to maintain a tight seal under various operating conditions, contributing to the overall performance and reliability of the truck 2.

Key Features of the 3045877 O Ring Seal

The Cummins 3045877 O Ring Seal is characterized by several key features that enhance its performance. These include its material composition, which is designed to withstand the harsh conditions encountered in commercial truck engines. The seal is also engineered for durability, ensuring long-term reliability. Additionally, its design characteristics are tailored to provide an effective seal in the specific applications for which it is intended.

Benefits of Using the 3045877 O Ring Seal

Utilizing the Cummins 3045877 O Ring Seal offers several benefits. These include improved sealing efficiency, which helps maintain system performance and prevent leaks. The seal’s durability ensures longevity, reducing the need for frequent replacements. Furthermore, its reliability in harsh operating conditions contributes to the overall dependability of the truck’s engine and systems 3.

Installation and Maintenance

Proper installation of the Cummins 3045877 O Ring Seal is vital for its effectiveness. Best practices include ensuring the mating surfaces are clean and free of debris before installation. It is also important to avoid over-tightening, which can damage the seal. Regular maintenance, such as periodic inspection for wear or damage, can help ensure the longevity and effectiveness of the seal.

Troubleshooting Common Issues

Common issues with O Ring Seals, such as leaks or wear, can often be traced to installation errors or environmental factors. Troubleshooting steps may include inspecting the seal for proper seating, checking for damage, and ensuring that the mating surfaces are in good condition. Addressing these issues promptly can help maintain the seal’s effectiveness and prevent more significant problems.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a broad product range, Cummins has established a reputation for quality and reliability in the commercial truck industry. This context underscores the quality and reliability of the 3045877 O Ring Seal, reflecting Cummins’ commitment to excellence in its products.

O Ring Seal 3045877 Compatibility with Cummins Engines

The O Ring Seal 3045877, manufactured by Cummins, is designed to fit a variety of Cummins engines. This seal is crucial for maintaining the integrity of the engine’s sealing systems, ensuring that there are no leaks and that the engine operates efficiently. Below is a breakdown of the engines with which this O Ring Seal is compatible:

ISC CM554 and ISL CM554

The ISC CM554 and ISL CM554 engines are part of Cummins’ lineup of medium-duty diesel engines. The O Ring Seal 3045877 is compatible with these engines, providing a reliable seal in various applications.

ISM CM554, ISM CM570, ISM CM570/870, and ISM CM876

These engines are part of Cummins’ medium-duty diesel engine family and are known for their durability and performance. The O Ring Seal 3045877 fits seamlessly with these models, ensuring optimal sealing and performance.

ISM11 CM876 SN and QSC8.3 CM554

The ISM11 CM876 SN and QSC8.3 CM554 engines are designed for heavy-duty applications. The O Ring Seal 3045877 is engineered to provide a robust seal for these engines, enhancing their operational efficiency.

QSL9 CM554 and QSM11 CM570

These engines are part of Cummins’ medium-duty diesel engine range and are used in various applications. The O Ring Seal 3045877 is compatible with these engines, ensuring that they maintain their sealing integrity.

QSM11 CM876, QSN14 CM876 N103, and QSNT14 CM876 N102

These engines are part of Cummins’ heavy-duty diesel engine lineup. The O Ring Seal 3045877 is designed to fit these engines, providing a reliable seal that is essential for their performance and longevity.

L10 CELECT, M11 CELECT, M11 CELECT PLUS, N14 CELECT, and N14 CELECT PLUS

These engines are part of Cummins’ CELECT family, known for their advanced technology and efficiency. The O Ring Seal 3045877 is compatible with these engines, ensuring that they maintain their sealing integrity and operate efficiently.

The O Ring Seal 3045877 is a versatile and essential component for maintaining the sealing integrity of various Cummins engines. Its compatibility with a wide range of engine models ensures that it can be used in multiple applications, providing reliable performance and durability.

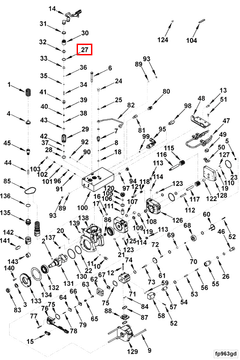

Role of Part 3045877 O Ring Seal in Engine Systems

The O Ring Seal (part 3045877) is instrumental in ensuring the integrity and efficiency of various engine components. Its application spans across multiple systems, providing essential sealing functions that prevent leaks and maintain pressure.

Solenoid Valve

In the solenoid valve, the O Ring Seal is positioned to create a tight seal between the valve body and the plunger. This ensures that the fluid or gas flow is controlled precisely without any leakage, which is vital for the valve’s operation and the overall system performance.

Accumulator

Within the accumulator, the O Ring Seal plays a key role in sealing the interface between the body and the plunger. This seal is necessary to maintain the pressure integrity of the accumulator, ensuring it can store and release energy efficiently when required.

Cam Housing Module

The cam housing module relies on the O Ring Seal to prevent any fluid or gas escape between the housing and the camshaft. This seal is essential for maintaining the module’s functionality and ensuring smooth operation of the camshaft.

Cylinder Head

In the cylinder head, the O Ring Seal is used to ensure a secure seal around injectors and other components. This helps in maintaining the combustion chamber’s pressure and preventing any fuel or coolant leaks, which is fundamental for engine performance and durability.

Fuel Injection Pump and Fuel Pump

For the fuel injection pump and fuel pump, the O Ring Seal is critical in sealing connections between various parts, such as the pump body and the plunger. This ensures that fuel is delivered under the correct pressure without any leaks, which is essential for efficient engine operation.

Injector Body and Injectors

The O Ring Seal is utilized in the injector body to create a seal around the injectors. This prevents fuel leakage and ensures that the injectors operate under the precise conditions required for optimal fuel delivery and combustion.

Engine Piston Kit and Connecting Rod

In the engine piston kit and connecting rod assemblies, the O Ring Seal is employed to seal various interfaces, such as between the piston and the cylinder wall. This helps in maintaining compression and preventing any lubricant leakage, which is important for the longevity and performance of these components.

EBM-Injector and EBM-Performance Parts

For EBM-injectors and EBM-performance parts, the O Ring Seal ensures that all connections are leak-free. This is particularly important in high-performance applications where precision and reliability are paramount.

Fuel Pump Kit

In the fuel pump kit, the O Ring Seal is used to seal the pump housing and other critical interfaces. This ensures that the fuel system operates under the correct pressure and without leaks, which is essential for the engine’s fuel efficiency and performance.

The O Ring Seal (part 3045877) thus serves as a fundamental component in various engine systems, ensuring that seals are maintained, pressures are preserved, and leaks are prevented, contributing to the overall reliability and efficiency of the engine.

Conclusion

The Cummins 3045877 O Ring Seal is a critical component in the maintenance and operation of commercial truck engines. Its role in preventing leaks, maintaining system efficiency, and ensuring the reliable operation of trucks under demanding conditions cannot be overstated. The seal’s compatibility with a wide range of Cummins engines, coupled with its durability and reliability, makes it an essential part for maintaining the integrity of engine systems. Proper installation and maintenance of this part are vital for its effectiveness, ensuring the longevity and performance of the truck’s engine and systems.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.