3082459

O Ring Seal

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3082459 O Ring Seal is a critical component designed to maintain the integrity of seals within commercial truck systems. Its primary function is to prevent leaks and ensure system efficiency. In the context of commercial truck maintenance and operation, this part plays a significant role by providing a reliable seal in various applications, contributing to the overall performance and longevity of the truck.

Basic Concepts of O Ring Seals

An O Ring Seal is a type of gasket that forms a seal by being compressed within a groove. Its fundamental design is a circular cross-section, which allows it to create a tight seal when compressed. Commonly used materials for O Ring Seals include rubber, silicone, and fluorocarbon, each offering different properties such as temperature resistance, chemical compatibility, and durability 1. The function of an O Ring Seal in mechanical systems is to prevent the leakage of fluids or gases, ensuring the system operates efficiently.

Role of the 3082459 O Ring Seal in Truck Operation

The 3082459 O Ring Seal is specifically designed to ensure the integrity of seals in various systems or components within commercial trucks. It is commonly associated with fuel systems, hydraulic systems, and engine components where maintaining a seal is crucial for performance. By providing a reliable seal, this Cummins part contributes to the efficient operation of these systems, preventing leaks that could lead to decreased performance or system failure.

Key Features of the 3082459 O Ring Seal

The 3082459 O Ring Seal features a design that is optimized for its intended application in commercial trucks. It is made from materials that offer excellent resistance to the temperatures and chemicals typically encountered in truck operations. Unique characteristics of the 3082459 O Ring Seal include its durability, flexibility, and ability to maintain a seal under pressure, making it suitable for demanding applications.

Benefits of Using the 3082459 O Ring Seal

Using the 3082459 O Ring Seal offers several benefits, including improved sealing performance, enhanced durability, and increased reliability in demanding truck applications. Its design and material properties ensure that it can withstand the rigors of commercial truck operation, providing a long-lasting seal that contributes to the efficiency and reliability of the truck’s systems.

Installation Considerations

For the installation of the 3082459 O Ring Seal, it is important to follow guidelines and best practices to ensure optimal performance and longevity. Proper handling of the O Ring Seal is crucial to avoid damage. Lubrication with a compatible lubricant is recommended to facilitate installation and reduce the risk of damage. Torque specifications should be adhered to during installation to ensure the seal is properly compressed without being overtightened, which could lead to failure 2.

Troubleshooting Common Issues

Common issues that may arise with O Ring Seals in truck applications include leaks, damage from improper installation, and degradation over time. Troubleshooting steps may involve inspecting the seal for signs of wear or damage, ensuring proper installation techniques were used, and replacing the seal if necessary. Solutions to address these problems effectively include using the correct lubricant during installation, following torque specifications, and regularly inspecting seals for signs of wear.

Maintenance and Replacement

To ensure continued reliable operation and prevent potential failures or leaks, it is recommended to maintain and periodically replace the 3082459 O Ring Seal. Regular inspections should be conducted to check for signs of wear, damage, or degradation. Replacement should be performed according to the manufacturer’s recommendations or when signs of failure are detected. Proper maintenance and timely replacement of the O Ring Seal contribute to the overall reliability and efficiency of the truck’s systems.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins has established a strong reputation in the commercial truck industry. The company’s commitment to quality and innovation is evident in its product offerings, which include a wide range of engines and components designed to meet the demanding requirements of commercial truck applications 3.

Compatibility with Engine Models

The Cummins O Ring Seal part number 3082459 is designed to fit a variety of Cummins engine models, ensuring a reliable seal in various applications. Here is a detailed breakdown of the compatibility of this part with different engine series:

Cummins QSK Series

- QSK45 CM500

- QSK60 CM500

- QSK60 G CM2358 K110

- QSK60G

- QSK78 CM500

Cummins QSK95 Series

- QSK95 CM2350 K111

- QSK95 CM2350 K113

Cummins QSV Series

- QSV81G

- QSV91G

Cummins QSW/QSV Series

- QSW/QSV82

Cummins QSW Series

- QSW27

- QSW36

- QSW73

By ensuring compatibility with these various engine models, the 3082459 O Ring Seal from Cummins provides a reliable sealing solution across a wide range of heavy-duty applications.

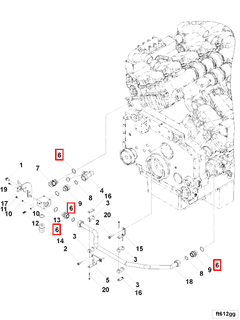

Role of Part 3082459 O Ring Seal in Engine Systems

The O Ring Seal, identified by part number 3082459, is integral to the reliable operation of various engine components. Its primary function is to ensure a tight seal, preventing leaks and maintaining system integrity. Here’s how it interfaces with several key engine systems:

Camshaft and Gear Assembly Housing

In the camshaft and gear assembly housing, the O Ring Seal is used to secure the seals around rotating components. This prevents oil leakage, ensuring consistent lubrication and reducing wear on moving parts.

Check Valve and Fuel Drain Plumbing

Within the check valve and fuel drain plumbing, the O Ring Seal plays a role in maintaining pressure integrity. It ensures that fuel or other fluids do not escape, which is essential for the proper functioning of these systems.

Coolant Heater Starting Aid and Preheater Assembly Tube

For the coolant heater starting aid and preheater assembly tube, the O Ring Seal is vital in maintaining the seal around connections. This ensures that coolant flows efficiently without leaks, which is crucial for effective engine preheating and starting in cold conditions.

Crankcase Breather Arrangement and Expansion Assembly Tank

In the crankcase breather arrangement and expansion assembly tank, the O Ring Seal helps to contain crankcase gases and coolant expansion. This prevents contamination and maintains the efficiency of these systems.

Flywheel Housing and Front Gear Train Accessory Drive

The flywheel housing and front gear train accessory drive rely on the O Ring Seal to maintain seals around rotating and stationary components. This ensures that lubricants remain contained, supporting smooth operation and longevity of these parts.

Fuel Filter, Fuel Filter Head, and Full Flow Assembly Filter

For the fuel filter, fuel filter head, and full flow assembly filter, the O Ring Seal is essential in securing connections. This prevents fuel leaks and ensures that the filtration process is effective, contributing to clean fuel delivery to the engine.

Fuel Pump and Lubricating Oil Pump

In both the fuel pump and lubricating oil pump, the O Ring Seal ensures that seals around pump components are maintained. This is important for consistent pressure and flow, which are vital for the efficient operation of these pumps.

Heat Assembly Exchanger and Heat Exchanger

The heat assembly exchanger and heat exchanger utilize the O Ring Seal to maintain the integrity of fluid pathways. This ensures efficient heat transfer and prevents leaks, which is essential for the proper functioning of these components.

Oil Filter Housing and Plain Hose Coupling

In the oil filter housing and plain hose coupling, the O Ring Seal is used to secure connections and prevent oil leaks. This is important for maintaining oil pressure and ensuring that the filtration process is effective.

Preheater Equipped Housing and Priming Pump

For the preheater equipped housing and priming pump, the O Ring Seal ensures that seals around these components are maintained. This is essential for effective preheating and priming, which are important for engine start-up and operation.

Service Kit and Threaded Plug

In service kits and around threaded plugs, the O Ring Seal is often included to ensure that replacements or new installations maintain a tight seal. This is important for the longevity and reliability of these components.

Turbocharger Oil Plumbing

Finally, in turbocharger oil plumbing, the O Ring Seal ensures that oil seals are maintained, which is essential for the efficient lubrication and cooling of the turbocharger. This contributes to the overall performance and durability of the turbocharger system.

Conclusion

The Cummins 3082459 O Ring Seal is a vital component in maintaining the integrity and efficiency of commercial truck systems. Its design and material properties ensure durability and reliability in demanding applications. Proper installation, maintenance, and timely replacement are essential to maximize the benefits of this part, contributing to the overall performance and longevity of the truck.

-

Robert Bosch GmbH. (2007). Bosch Automotive Electrics and Automotive Electronics: Systems and Components, Networking and Hybrid Drive 5th Edition. Springer Vieweg.

↩ -

Forbes Aird. (2001). Bosch Fuel Injection Systems. HP Books.

↩ -

Andrew Brown Jr. (2010). Technologies and Approaches to Reducing the Fuel Consumption of Medium and Heavy-Duty Vehicles. National Academy of Sciences.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.