This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3084848 O-Ring Seal is designed to maintain the integrity of seals within commercial truck systems. It plays a significant role in ensuring the efficiency and reliability of truck operations by preventing leaks and ensuring proper system function. This contributes to the overall performance and longevity of commercial vehicles 1.

Basic Concepts of O-Ring Seals

An O-Ring Seal is a type of gasket that forms a seal by being squeezed into a groove. It operates on the principle of elastomeric deformation, where the O-Ring is compressed between two surfaces to create a barrier against fluids or gases. This design allows it to adapt to various shapes and sizes, making it versatile for different applications in mechanical systems 2.

Purpose of the 3084848 O-Ring Seal in Truck Operation

The 3084848 O-Ring Seal ensures seals in critical areas such as fuel systems, hydraulic systems, and engine components. It supports these systems by maintaining pressure integrity and preventing leaks, which is vital for the efficient operation of the truck.

Key Features

This Cummins part is characterized by its material composition, typically made from durable elastomers that offer resistance to a range of environmental factors. Its design specifications include precise dimensions to fit specific grooves and applications, ensuring a snug fit and effective sealing. Unique characteristics may include enhanced flexibility and resistance to wear, contributing to its performance.

Benefits of Using the 3084848 O-Ring Seal

Utilizing the 3084848 O-Ring Seal offers several advantages, including improved sealing efficiency, which helps in maintaining system pressure and preventing leaks. Its durability ensures long-term performance, while its resistance to various environmental factors, such as temperature extremes and chemical exposure, enhances its reliability in demanding truck operations.

Installation Guidelines

Proper installation of the 3084848 O-Ring Seal involves several steps to ensure optimal performance. It should be lubricated before insertion to facilitate easy placement into the groove. Care must be taken to avoid damage to the O-Ring during installation. Ensuring the groove is clean and free of debris is also crucial for a secure fit and effective seal.

Troubleshooting Common Issues

Common problems with O-Ring Seals may include leaks, which can be caused by improper installation, wear and tear, or exposure to incompatible fluids. Troubleshooting steps involve inspecting the O-Ring for signs of damage, ensuring it is correctly seated in the groove, and verifying compatibility with the system’s fluids and operating conditions.

Maintenance Tips

Maintaining the 3084848 O-Ring Seal involves regular inspection for signs of wear, such as cracks or deformation. It is advisable to replace the O-Ring Seal according to the manufacturer’s guidelines or when signs of degradation are observed. Keeping the sealing surfaces clean and free of contaminants also contributes to the longevity of the O-Ring Seal.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins serves commercial, industrial, and automotive markets. The company’s commitment to excellence is reflected in its wide range of products, including the 3084848 O-Ring Seal, designed to meet the demanding requirements of commercial truck applications.

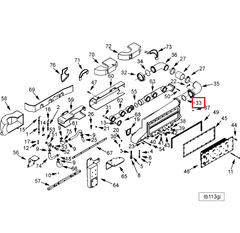

Cummins O-Ring Seal 3084848 in Engine Applications

The Cummins O-Ring Seal part number 3084848 is a critical component in ensuring the integrity and efficiency of various engine systems. This seal is integral to the operation of the QSC8.3 CM850 (CM2850) engines, where it plays a pivotal role in preventing leaks and maintaining pressure within the engine’s hydraulic and lubrication systems.

In the QSC8.3 CM850 (CM2850) engines, the O-Ring Seal 3084848 is typically used in conjunction with high-pressure components, such as fuel injectors, hydraulic systems, and various other fluid pathways. Its design and placement are crucial for maintaining the engine’s performance and longevity. The seal’s material and construction are specifically engineered to withstand the high temperatures, pressures, and chemical environments found within these engines.

The O-Ring Seal 3084848 is also compatible with other Cummins engines that share similar design and operational characteristics with the QSC8.3 CM850 (CM2850). This includes other models within the Cummins QSC series, where the seal’s function and importance remain consistent. The seal’s ability to form a reliable barrier against fluid and gas leakage is essential for the overall reliability and efficiency of these engines.

Role of Part 3084848 O-Ring Seal in Engine Systems

The part 3084848 O-Ring Seal is an essential component in various engine systems, ensuring the integrity and efficiency of these systems.

In the Campaign Kit, the O-Ring Seal is utilized to create a tight seal between different components, preventing leaks and ensuring that fluids and gases remain contained within their designated pathways. This is particularly important in systems where pressure differentials exist, as even minor leaks can lead to significant performance issues.

Within the Overhaul Gasket Set, the O-Ring Seal plays a significant role in maintaining the seal between mating surfaces. This is vital for components such as the cylinder head, intake manifold, and exhaust manifold, where precise sealing is required to maintain engine efficiency and prevent the escape of combustion gases.

In the context of an Overhaul Kit, the O-Ring Seal is often included to replace worn or damaged seals during a comprehensive engine rebuild. This ensures that all seals are in optimal condition, contributing to the overall reliability and performance of the engine post-overhaul.

For the Turbocharger Arrangement, the O-Ring Seal is used in various connections, such as the turbocharger to manifold connection and the oil feed and return lines. These seals are essential for maintaining the turbocharger’s efficiency by ensuring that there are no leaks in the oil system or the air pathways, which could otherwise lead to decreased performance and potential damage.

Lastly, in the Upper Engine Gasket Set, the O-Ring Seal is employed to ensure a proper seal between the upper engine components. This includes seals for the valve cover, PCV system, and any other upper engine components that require a fluid-tight seal to function correctly.

Overall, the part 3084848 O-Ring Seal is a fundamental component in ensuring the sealing integrity across various engine systems, contributing to the engine’s overall performance, efficiency, and longevity.

Conclusion

The Cummins 3084848 O-Ring Seal is a vital component in maintaining the integrity and efficiency of commercial truck and engine systems. Its role in preventing leaks, ensuring proper system function, and contributing to the overall performance and longevity of vehicles is significant. Proper installation, maintenance, and understanding of its key features and benefits are essential for maximizing its effectiveness in demanding applications.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.