3092613

O Ring Seal

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The O Ring Seal 3092613, manufactured by Cummins, is a component utilized in commercial trucks. Cummins, a well-established name in the commercial truck industry, produces a range of parts designed to enhance the performance and reliability of trucks. Seals, such as the O Ring Seal 3092613, play a role in maintaining system integrity by preventing leaks and ensuring that systems operate within specified parameters 1.

Basic Concepts of O Ring Seals

An O Ring Seal is a type of gasket that has a circular cross-section. It is designed to create a seal between two or more parts. The basic structure of an O Ring Seal involves a loop of elastomeric material that fits into a groove. Common materials for O Ring Seals include rubber, silicone, and fluorocarbon. These materials are chosen for their flexibility, resilience, and resistance to various chemicals and temperatures 2. The O Ring Seal functions by deforming slightly when compressed between two surfaces, thereby creating a seal that prevents the passage of fluids or gases.

Role of the 3092613 O Ring Seal in Truck Operation

The 3092613 O Ring Seal is involved in the operation of commercial trucks by ensuring the integrity of seals in various systems or components. It is typically used in applications where fluid or gas containment is required, such as in fuel systems, hydraulic systems, or engine compartments. By maintaining a reliable seal, the 3092613 O Ring Seal contributes to the efficient operation of these systems 3.

Key Features of the 3092613 O Ring Seal

The 3092613 O Ring Seal is characterized by its design and material properties. It is made from a material that offers resistance to the specific fluids and temperatures it will encounter in its application. The seal is designed to fit into a specific groove, ensuring a snug fit that enhances its sealing capabilities. Unique characteristics of the 3092613 O Ring Seal may include specialized compounds or treatments that improve its performance in demanding environments 4.

Benefits of Using the 3092613 O Ring Seal

The use of the 3092613 O Ring Seal offers several benefits. It contributes to improved system efficiency by ensuring that fluids or gases remain contained within their intended paths. The seal’s design and material properties support its longevity, reducing the frequency of replacements. Additionally, the reliability of the 3092613 O Ring Seal in demanding truck environments helps maintain system integrity and performance.

Installation and Maintenance Guidelines

Proper installation of the 3092613 O Ring Seal is important for optimal performance. It should be lubricated before installation to facilitate easy placement into the groove. Care should be taken to avoid damaging the seal during installation. Regular maintenance, such as inspection for wear or damage, can help prolong the life of the seal and ensure continued system integrity.

Troubleshooting Common Issues

Common issues with O Ring Seals, such as leaks or failures, can often be traced to installation errors, material degradation, or environmental factors. Identifying the source of the problem is the first step in troubleshooting. Solutions may involve replacing the seal, adjusting the system to reduce stress on the seal, or modifying the environment to better suit the seal’s material properties.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and reliability in the commercial truck industry. The company’s product range includes engines, powertrains, and aftermarket parts, all designed to meet the demanding requirements of commercial applications. Cummins is recognized as a trusted source for truck components, offering parts that contribute to the efficiency, reliability, and performance of commercial vehicles.

Role of Part 3092613 O Ring Seal in Engine Systems

The O Ring Seal, identified by part number 3092613, is integral to the functionality and efficiency of various engine components. Its application spans across several key areas within the engine system, ensuring optimal performance and longevity of the engine.

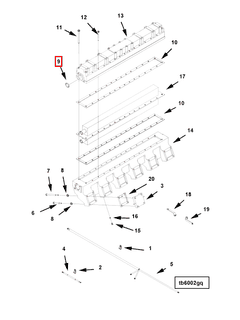

Aftercooler and Aftercooler Assemblies

In the aftercooler and its assemblies—both left and right banks—the O Ring Seal plays a significant role. It is positioned at the interfaces where the aftercooler connects to other components, such as the air intake manifold and the turbocharger arrangement. The seal ensures that the cooling process of the compressed air is efficient by preventing any unwanted air leakage. This results in improved air density and, consequently, better engine performance.

Turbocharger Arrangement

Within the turbocharger arrangement, the O Ring Seal is utilized at various connection points. Its primary function here is to maintain the integrity of the pressurized air system. By sealing the connections between the turbocharger and other components, it ensures that the pressurized air is delivered efficiently to the engine, enhancing overall engine power and responsiveness.

Plumbing and Aftercooler Water System

In the plumbing of the aftercooler water system, the O Ring Seal is employed to ensure that the cooling water circulates effectively without any leaks. This is vital for maintaining the temperature of the aftercooler, which directly affects the efficiency of the air cooling process. A well-sealed system ensures that the aftercooler operates within its optimal temperature range, contributing to the engine’s reliability and performance.

Upper Engine Gasket Kit

The O Ring Seal is also a component of the upper engine gasket kit. Here, it is used in conjunction with other gaskets to seal various engine components, such as the cylinder head and intake manifold. Its role is to prevent any gas or fluid leakage, which is essential for maintaining the engine’s compression and ensuring that all components operate within their designed parameters.

Conclusion

In summary, the O Ring Seal (part 3092613) is a versatile component that enhances the efficiency and reliability of several engine systems. Its application in aftercoolers, turbochargers, plumbing systems, and gasket kits underscores its importance in maintaining the optimal operation of these components.

-

Lakshminarayanan, P A, and Yogesh V Aghav. Modelling Diesel Combustion. Springer Science, 2010.

↩ -

Dixon, John. Modern Diesel Technology Preventive Maintenance and Inspection. Delmar Cengage Learning, 2010.

↩ -

Gifford, Clive. Cars Encyclopedia. DK Publishing, 2014.

↩ -

Viskup, Richard. Diesel and Gasoline Engines. IntechOpen, 2020.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.