This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3167229 O Ring Seal is a component designed to ensure the integrity of seals within commercial truck engines. Its role is to prevent leaks and maintain system efficiency, contributing to the overall performance and reliability of the vehicle.

Basic Concepts of O Ring Seals

An O Ring Seal is a toroidal (donut-shaped) elastomer seal that creates a barrier between two or more parts. It functions by deforming under compression to fill the gap between mating surfaces, thereby preventing the passage of fluids or gases. O Ring Seals are widely used in mechanical systems due to their simplicity, effectiveness, and versatility in various applications 1.

Purpose of the Cummins 3167229 O Ring Seal

The Cummins 3167229 O Ring Seal is specifically designed to fit within the engine or other systems of a truck, where it plays a role in maintaining the seal between components. Its placement is critical in areas where fluid or gas containment is necessary to ensure the engine operates efficiently and without leaks.

Key Features

The Cummins 3167229 O Ring Seal is constructed from materials that offer high durability and resistance to the harsh conditions found in heavy-duty applications. Its design characteristics, including precise dimensions and material composition, make it well-suited for the demanding environments of commercial trucks.

Benefits

Utilizing the Cummins 3167229 O Ring Seal offers several advantages, such as enhanced sealing efficiency, extended service life, and the ability to withstand a range of operating conditions. These benefits contribute to the overall reliability and performance of the truck’s engine system 2.

Installation Considerations

Proper installation of the Cummins 3167229 O Ring Seal is vital to ensure its effectiveness and longevity. Guidelines suggest careful handling to avoid damage, correct seating within the groove, and verification of a proper seal before system operation.

Troubleshooting Common Issues

Common problems with O Ring Seals may include leaks, deformation, or failure due to wear and tear. Troubleshooting steps involve inspecting the seal for damage, ensuring correct installation, and replacing the seal if necessary to restore system integrity.

Maintenance Tips

Regular maintenance of the Cummins 3167229 O Ring Seal involves periodic inspection for signs of wear or damage, cleaning the seal and its seating area, and replacing the seal according to the manufacturer’s recommendations or when signs of degradation are observed.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a rich history in the industry, Cummins is recognized for its commitment to quality and innovation in automotive components, including O Ring Seals that play a significant role in ensuring the reliability and performance of their engines 3.

Role of Part 3167229 O Ring Seal in Engine Systems

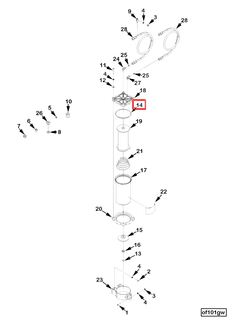

The Part 3167229 O Ring Seal is instrumental in ensuring the integrity and efficiency of various engine systems. Its application spans across multiple components, each playing a distinct role in the overall functionality of the engine.

Integration with Engine Components

-

Bracket Throttle Kit:

- The O Ring Seal is utilized in the bracket throttle kit to create a secure and leak-proof connection between the throttle body and the intake manifold. This ensures that air enters the engine consistently, contributing to stable engine performance.

-

Bypass Filter Mounting:

- In the bypass filter mounting system, the O Ring Seal prevents oil leaks by sealing the connection points. This is essential for maintaining the pressure integrity within the bypass filter, ensuring that contaminants are effectively filtered out without any loss of lubricant.

-

Filter Super Bypass Kit:

- The O Ring Seal is critical in the filter super bypass kit for sealing the bypass valve. This prevents unfiltered oil from entering the engine under high-pressure conditions, thus protecting engine components from wear and damage.

-

Filter:

- When installed in standard filter applications, the O Ring Seal ensures that the filter housing remains sealed, preventing any bypass of unfiltered oil. This maintains the cleanliness of the engine’s lubricant, prolonging the life of internal components.

-

Lo Bypass:

- In low bypass systems, the O Ring Seal is used to maintain the seal at various connection points, ensuring that the bypass function operates correctly without any leakage. This is vital for engines that require precise oil flow management.

-

Lubricating Oil Bypass Filter:

- The O Ring Seal in lubricating oil bypass filters ensures that the filter media is effectively sealed, allowing only clean oil to re-enter the system. This enhances the lubrication quality and reduces the risk of engine wear.

-

Oil Bypass Filter:

- Similar to the lubricating oil bypass filter, the O Ring Seal in standard oil bypass filters ensures a tight seal, preventing any unfiltered oil from contaminating the system. This is key to maintaining optimal engine performance.

-

Oil Bypass Filter Arrangement:

- In complex oil bypass filter arrangements, the O Ring Seal is used at multiple junctures to ensure a comprehensive seal. This setup is designed to handle higher flow rates and maintain filtration efficiency under varying operating conditions.

-

Spares Kit:

- Included in spares kits, the O Ring Seal is a vital component for maintenance and repair. It allows for the replacement of worn or damaged seals, ensuring that the engine system remains leak-free and operates efficiently.

The effective use of the Part 3167229 O Ring Seal across these components underscores its importance in maintaining the performance and longevity of engine systems.

Conclusion

The Cummins 3167229 O Ring Seal plays a crucial role in maintaining the integrity and efficiency of commercial truck engines. Its design, material composition, and application across various engine components highlight its importance in ensuring reliable and optimal engine performance.

-

Goodnight, N., & VanGelder, K. (2019). Automotive Braking Systems CDX Master Automotive Technician Series. Jones Bartlett Learning.

↩ -

Taghavifar, H., & Mardani, A. (2017). Offroad Vehicle Dynamics Analysis Modelling and Optimization. Springer.

↩ -

Schneider, W.-H. (2016). Pistons and Engine Testing. Springer Nature.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.