3393303

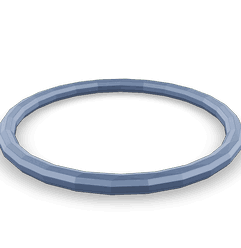

O Ring Seal

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3393303 O Ring Seal is a critical component designed to ensure the integrity of seals in commercial truck operations. Its role is significant in maintaining the efficiency and reliability of truck systems by preventing leaks and ensuring proper system function.

Basic Concepts of O Ring Seals

An O Ring Seal is a type of gasket consisting of a jointless ring of elastomeric material used for sealing applications. It functions by creating a barrier that prevents the passage of fluids and gases between mechanical parts. O Ring Seals are widely used in various mechanical systems due to their simplicity, effectiveness, and versatility in sealing applications 1.

Purpose of the 3393303 O Ring Seal in Truck Operations

The 3393303 O Ring Seal plays a specific role in the operation of commercial trucks by ensuring the integrity of seals in various systems. It is typically placed in areas where fluid or gas passage needs to be controlled, such as in fuel systems, hydraulic systems, and engine components. Its function is to create a reliable seal that prevents leaks, which can lead to system inefficiencies or failures.

Key Features of the 3393303 O Ring Seal

The design and material characteristics of the 3393303 O Ring Seal contribute to its effectiveness and durability in heavy-duty applications. It is made from high-quality elastomeric materials that offer resistance to a wide range of environmental factors, including temperature variations, chemical exposure, and mechanical stress. These features ensure that the seal maintains its integrity under the demanding conditions encountered in commercial truck operations 2.

Benefits of Using the 3393303 O Ring Seal

The 3393303 O Ring Seal provides several advantages, including improved sealing performance, longevity, and resistance to various environmental factors. Its design allows for a tight seal that minimizes the risk of leaks, while its durable materials ensure a long service life even under harsh operating conditions. Additionally, its resistance to environmental factors helps maintain system integrity and efficiency.

Installation Considerations

Proper installation of the 3393303 O Ring Seal is important to ensure optimal performance and longevity. Guidelines for installation include ensuring the sealing surface is clean and free of debris, using the correct amount of lubrication to facilitate seating, and avoiding over-tightening which can damage the seal. Following these best practices helps ensure the seal functions effectively and has a prolonged service life.

Troubleshooting Common Issues

Common problems associated with O Ring Seals include leaks, extrusion, and degradation. Troubleshooting steps may involve inspecting the seal for signs of wear or damage, checking the sealing surface for cleanliness and proper fit, and ensuring that installation procedures were followed correctly. Addressing these issues promptly can help maintain system integrity and prevent more significant problems.

Maintenance Tips

Regular maintenance of the 3393303 O Ring Seal can prolong its service life and maintain system integrity. Recommendations include periodic inspection for signs of wear or damage, cleaning the sealing surface as needed, and replacing the seal according to the manufacturer’s guidelines or when signs of degradation are observed. These practices help ensure the continued reliability of the sealing system.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a history of innovation and commitment to quality, Cummins serves customers in approximately 190 countries and territories, providing reliable and efficient power solutions for various applications, including commercial trucks.

Compatibility of 3393303 O Ring Seal with Cummins Engines

The 3393303 O Ring Seal, manufactured by Cummins, is designed to fit seamlessly with a range of engine models. This seal is crucial for maintaining the integrity of the engine’s system by preventing leaks and ensuring that the engine operates efficiently.

For the K19, K38, and K50 engines, the 3393303 O Ring Seal is engineered to fit precisely in areas where it is most needed, ensuring a tight seal that prevents any fluid or gas from escaping.

In the case of the QSK50 CM2150 and QSK50 CM2150 MCRS engines, the seal is specifically tailored to fit the unique design and requirements of these models, providing a reliable barrier against leaks in critical areas.

Similarly, for the QSK60 CM850 MCRS and QSK95 CM2350 engines, the 3393303 O Ring Seal is designed to integrate perfectly with the engine’s architecture, ensuring that it performs optimally under various operating conditions.

The seal’s compatibility extends to the QSK95 CM2350 K111 and QSK95 CM2350 K113 engines as well, where it is engineered to fit snugly and provide a dependable seal, contributing to the overall efficiency and longevity of the engine.

Role of Part 3393303 O Ring Seal in Engine Systems

The 3393303 O Ring Seal is integral to the efficient operation of various engine systems, ensuring that fluids are contained and systems remain sealed under pressure. Here’s how it interfaces with the provided components:

Cooling System

- Cooler and Heat Exchanger: The O Ring Seal is used in the assembly of coolers and heat exchangers to prevent coolant leaks. It ensures that the cooling fluid circulates efficiently without any loss, maintaining optimal engine temperature.

- Thermostat and Thermostat Housing: In the thermostat housing, the O Ring Seal helps to maintain a tight seal around the thermostat, ensuring that the coolant flow is regulated correctly as per the engine’s temperature requirements.

- Water Pump and Water Transfer Tubes: When installed in the water pump or within the water transfer tubes, the O Ring Seal prevents coolant leakage, ensuring consistent coolant flow throughout the engine.

Lubrication System

- Engine Oil and Lubricating Oil Filter Kit: In the oil filter housing, the O Ring Seal ensures that engine oil is contained within the system, preventing leaks that could lead to insufficient lubrication and increased wear on engine components.

- Oil Cooler Repair Kit: Within the oil cooler, the O Ring Seal maintains the integrity of the oil passages, ensuring that the oil is cooled efficiently before returning to the engine.

Plumbing and Manifolds

- Manifold and Plumbing Components: The O Ring Seal is utilized in various plumbing connections and manifolds to ensure that fluids, whether coolant or oil, are directed accurately without any leakage, preserving system efficiency.

- Return Tube Water and Service Kit: In return tubes and service kits, the O Ring Seal plays a vital role in sealing connections, ensuring that fluids return to their respective reservoirs without any loss.

Gasket Kits

- Cooling System Gasket Kit and Gasket Kit: The O Ring Seal complements gaskets in complex assemblies, providing an additional layer of sealing where gaskets alone might not suffice, especially in high-pressure areas.

Specialized Components

- Heat Exchanger Mounting and Housing: In heat exchanger mountings and housings, the O Ring Seal ensures that the exchanger remains sealed, allowing for efficient heat transfer without fluid loss.

- Water Bypass Tube and Water Painted Pump: In bypass tubes and specialized pumps, the O Ring Seal ensures that alternative fluid paths are sealed, maintaining system pressure and flow integrity.

Conclusion

The 3393303 O Ring Seal, through its applications in these components, plays a significant role in maintaining the operational integrity of engine systems, ensuring that fluids are contained and systems operate under the designed pressures and temperatures.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.