This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3417027 O Ring Seal is a component designed to ensure the integrity of seals within commercial truck systems. Its role is significant in maintaining the efficiency and reliability of truck operations by preventing leaks and ensuring proper system function 1.

Basic Concepts of O Ring Seals

An O Ring Seal is a type of gasket consisting of a toroidal (ring-shaped) piece of elastomeric material. It is designed to create a seal between two or more parts. O rings are commonly made from materials such as nitrile rubber, silicone, or fluorocarbon elastomers, chosen for their resilience, flexibility, and resistance to various chemicals and temperatures. The seal functions by deforming slightly when compressed between two surfaces, filling any irregularities and creating a barrier to fluids or gases 2.

Purpose of the 3417027 O Ring Seal in Truck Operation

The 3417027 O Ring Seal plays a specific role in the operation of a truck by ensuring the integrity of seals in various systems or components. It is often associated with fuel systems, where it helps maintain the seal between components to prevent fuel leaks and ensure efficient fuel delivery 3.

Key Features of the 3417027 O Ring Seal

The 3417027 O Ring Seal is characterized by its precise design and material properties. It is crafted from high-quality elastomeric material, providing resilience and flexibility. Its unique characteristics include resistance to a wide range of temperatures and chemicals, ensuring reliable performance in demanding truck applications.

Benefits of Using the 3417027 O Ring Seal

The advantages of using the 3417027 O Ring Seal include enhanced sealing efficiency, durability, and reliability. Its design and material properties contribute to a robust seal, reducing the risk of leaks and improving the overall performance and longevity of truck systems.

Installation Considerations

Proper installation of the 3417027 O Ring Seal is vital for optimal performance and longevity. Guidelines recommend ensuring the seal is correctly sized and free from defects before installation. It should be lubricated with a compatible lubricant to facilitate easy insertion and prevent damage. Careful handling and correct placement within the system are crucial to maintain sealing integrity.

Troubleshooting Common Issues

Common problems associated with O Ring Seals, such as leaks or failures, can often be traced to installation errors, material degradation, or incompatible operating conditions. Troubleshooting steps include inspecting the seal for signs of wear or damage, ensuring correct installation, and verifying that the seal material is compatible with the operating environment.

Maintenance Tips

Regular maintenance of the 3417027 O Ring Seal is recommended to prolong its service life and maintain sealing integrity. This includes periodic inspection for signs of wear or degradation and replacement according to the manufacturer’s guidelines or as part of routine system maintenance. Keeping the seal and its surrounding components clean and free from contaminants also contributes to its longevity.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a history of innovation and a commitment to quality, Cummins has established a strong reputation in the commercial truck industry. Its product range is designed to meet the demanding requirements of commercial applications, ensuring reliability, efficiency, and performance.

Cummins Engine Part 3417027 O Ring Seal Compatibility

The Cummins part 3417027 O Ring Seal is designed to fit various Cummins engines, ensuring a secure seal to prevent leaks and maintain system integrity. Here are the engines with which this O Ring Seal is compatible:

B6.7 Series Engines

- B6.7 CM2350 B135B

- B6.7 CM2670 B153B

These engines are part of the B6.7 series, known for their robust performance and reliability in heavy-duty applications.

ISB/ISD Series Engines

- ISB/ISD6.7 CM2150 SN

- ISL9 CM2150 SN

The ISB/ISD series engines, including the ISL9 variant, are widely used in various industries due to their efficiency and durability.

ISBE Series Engines

- ISBE CM2150

- ISBE4 CM850

The ISBE series engines are engineered for high performance and are often found in on-highway and vocational applications.

ISC Series Engine

- ISC CM850

The ISC engine is known for its reliability and is commonly used in various commercial and industrial applications.

QSB Series Engine

- QSB7 CM2880 B117

The QSB series engine is designed for off-road applications and is recognized for its durability and power.

This O Ring Seal is a critical component in maintaining the operational efficiency of these engines by ensuring that seals are tight and preventing any potential leaks.

Role of Part 3417027 O Ring Seal in Engine Systems

The O Ring Seal, part number 3417027, is an essential component in various engine systems, ensuring the integrity and efficiency of several key components.

In the Actuator Housing, the O Ring Seal provides a tight seal between the actuator and its housing, preventing any fluid leaks that could impair the actuator’s performance. This seal is vital for maintaining the precision and reliability of the actuator’s movements.

Within the Check Valve, the O Ring Seal ensures that the valve operates within its designed parameters by preventing backflow and maintaining pressure integrity. This is particularly important in systems where precise fluid dynamics are required.

For the Crankcase Breather system, the O Ring Seal plays a role in maintaining the seal between the breather and the engine block. This helps in managing crankcase pressure and preventing oil vapors from escaping, which is essential for engine health and emissions control.

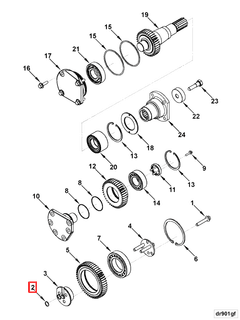

In the Idler Gear assembly, the O Ring Seal is used to secure the gear in place and prevent lubricant leakage. This ensures that the gear operates smoothly and efficiently, reducing wear and tear over time.

The Injector relies on the O Ring Seal to maintain a secure connection between the injector body and the fuel rail. This seal is important for preventing fuel leaks and ensuring that the injector delivers fuel at the correct pressure and timing.

When it comes to Kit assemblies, the O Ring Seal is often included to ensure that all components within the kit are properly sealed. This is particularly relevant in performance kits where maintaining seal integrity can enhance overall engine performance.

In the Repto system, the O Ring Seal is used to ensure that all connections are leak-free, which is essential for the system’s reliability and performance.

For the Performance Parts, the O Ring Seal is often a small but significant component that ensures all high-performance parts function as intended without leaks, which could otherwise degrade performance.

In the Rear Gear Housing, the O Ring Seal helps in maintaining the seal between the housing and the gear components. This is important for preventing lubricant loss and ensuring that the gears operate within their designed parameters.

Lastly, in the Solenoid Valve, the O Ring Seal ensures that the valve operates efficiently by maintaining a seal around the valve’s moving parts. This is important for the valve’s responsiveness and durability in various engine conditions.

Conclusion

The Cummins 3417027 O Ring Seal is a vital component in ensuring the efficiency and reliability of commercial truck systems. Its precise design, material properties, and compatibility with various Cummins engines make it an indispensable part of maintaining system integrity and preventing leaks. Proper installation, regular maintenance, and understanding its role in different engine systems are key to maximizing the performance and longevity of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.