This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3523958 O Ring Seal is a critical component designed to maintain the integrity of seals within commercial truck systems. It plays a significant role in ensuring the efficiency and reliability of truck operations by preventing leaks and ensuring proper system function.

Basic Concepts of O Ring Seals

An O Ring Seal is a toroidal (ring-shaped) elastomer with a circular cross-section used to create a seal between two or more parts. It functions by being compressed during assembly between a static and a dynamic part, creating a barrier that prevents the passage of fluids or gases. O Ring Seals are widely used in mechanical systems due to their simplicity, effectiveness, and versatility in various applications 1.

Purpose of the Cummins 3523958 O Ring Seal

The Cummins 3523958 O Ring Seal provides a reliable seal in engine or other systems where fluid or gas containment is required. Its function is to prevent leaks, maintain system pressure, and ensure the efficient operation of the truck’s components.

Key Features

This Cummins part is characterized by its material composition, typically made from durable elastomers that can withstand a range of temperatures and pressures. Its design is optimized for performance, featuring precise dimensions to ensure a snug fit and effective sealing. The durability of the seal is enhanced by its resistance to wear, chemical exposure, and environmental factors, making it suitable for the demanding conditions encountered in commercial truck operations 2.

Benefits

Utilizing the Cummins 3523958 O Ring Seal offers several advantages, including improved sealing efficiency, which contributes to the overall performance and reliability of the truck’s systems. Its longevity ensures that replacements are less frequent, reducing maintenance costs and downtime. The seal’s reliability in harsh operating conditions further enhances the truck’s operational efficiency and safety 3.

Installation Process

Proper installation of the Cummins 3523958 O Ring Seal is crucial for its performance and longevity. The process involves ensuring the sealing surfaces are clean and free of debris, selecting the correct size O Ring for the application, and carefully placing the O Ring into the groove without twisting or damaging it. Attention to these details during installation helps maintain the seal’s integrity and effectiveness 4.

Common Issues and Troubleshooting

Common issues with the Cummins 3523958 O Ring Seal may include leaks due to improper installation, damage from excessive compression, or degradation over time. Troubleshooting these problems involves inspecting the seal for signs of wear or damage, ensuring it is correctly seated, and replacing it if necessary. Addressing these issues promptly can prevent more significant problems and maintain the efficiency of the truck’s systems.

Maintenance Tips

To prolong the lifespan of the Cummins 3523958 O Ring Seal and ensure continued efficient operation, regular inspection routines are recommended. This includes checking for signs of wear, ensuring the sealing surfaces remain clean, and replacing the seal according to the manufacturer’s guidelines or when signs of degradation are observed. Adhering to these maintenance practices helps maintain the seal’s performance and reliability.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, emissions solutions, and related technologies. With a strong reputation in the commercial truck industry, Cummins is known for its innovative products, commitment to quality, and extensive product range that meets the diverse needs of its customers.

Role of Part 3523958 O Ring Seal in Engine Systems

In the realm of engine systems, the Cummins 3523958 O Ring Seal is integral to maintaining the efficiency and reliability of various components. Its application spans across multiple systems, ensuring that each part functions optimally.

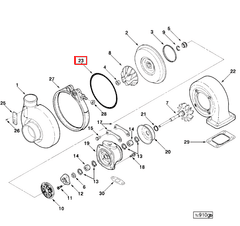

Turbocharger Systems

Within turbocharger systems, the O Ring Seal is employed to create a secure and leak-proof connection between the turbocharger and its housing. This seal is vital in preventing the escape of exhaust gases, which could lead to a loss in efficiency and potential damage to the turbocharger.

Aftermarket Turbocharger Integration

When integrating an aftermarket turbocharger, the O Ring Seal plays a significant role in adapting the new component to the existing engine system. It ensures a snug fit, which is essential for the turbocharger to operate within its designed parameters.

Engine Oil Cooler Systems

In engine oil cooler systems, the O Ring Seal is used to seal the connections between the cooler and the engine’s oil passages. This prevents oil leaks, which could lead to a drop in oil pressure and subsequent engine damage.

Core Assembly and Housing Repair Kits

For core assemblies and turbocharger housing repair kits, the O Ring Seal is a key component in reassembling the turbocharger after maintenance or repair. It ensures that the housing is securely sealed, preventing any air or gas leaks that could affect the turbocharger’s performance.

Fastener & Finishing Kits

In fastener & finishing kits, the O Ring Seal is often included to ensure that all connections made with fasteners are sealed properly. This is especially important in high-stress areas where vibrations and thermal expansion could otherwise lead to leaks.

General Turbocharger Applications

Across various turbocharger applications, whether stock or aftermarket, the O Ring Seal is a fundamental component. It ensures that the turbocharger operates within its designed efficiency range, contributing to the overall performance and longevity of the engine system.

Conclusion

The Cummins 3523958 O Ring Seal is a versatile and essential component in maintaining the integrity of various systems within commercial truck engines. Its role in preventing leaks, maintaining system pressure, and ensuring efficient operation cannot be overstated. Proper installation, regular maintenance, and prompt troubleshooting of issues are key to maximizing the performance and reliability of this critical part.

-

Automotive Braking Systems CDX Master Automotive Technician Series, Nicholas Goodnight and Kirk VanGelder, Jones Bartlett Learning, 2019.

↩ -

SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety, R. Matthew Brach, SAE International, 2023.

↩ -

Automotive Lubricants Reference Book, Arthur J Caines, Roger F Haycock and John E Hillier, SAE International, 2004.

↩ -

Diesel Engine Management Systems and Components, Konrad Reif, Springer, 2014.

↩

SPECIFICATIONS

BILL OF MATERIALS

| Name | Quantity | Part Number |

|---|---|---|

| Thrust Collar | 1 | 3518980 |

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.