This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3535600 O Ring Seal is a component designed to ensure the integrity of seals within commercial truck systems. Its role is significant in maintaining the operational efficiency and reliability of various truck systems by preventing leaks and ensuring proper system function.

Basic Concepts of O Ring Seals

An O Ring Seal is a type of gasket consisting of a toroidal (doughnut-shaped) piece of elastomeric material. It is designed to create a seal between two or more parts. The structure of an O Ring allows it to deform under compression, filling the gap between mating surfaces and preventing the passage of fluids or gases. Common materials for O Rings include nitrile rubber, silicone, and fluorocarbon, each chosen for specific applications based on their chemical resistance, temperature tolerance, and flexibility 1.

Purpose of the Cummins 3535600 O Ring Seal

The Cummins 3535600 O Ring Seal is utilized in various truck systems where sealing is required to maintain system integrity. It is commonly applied in fuel systems, hydraulic systems, and engine components. Its purpose is to create a reliable seal that prevents leaks, ensuring that fluids or gases remain contained within the system. This contributes to the overall efficiency and safety of the truck’s operation.

Key Features

The Cummins 3535600 O Ring Seal is characterized by its specific design and material properties. It is made from a durable elastomer that offers excellent resistance to the chemicals and temperatures encountered in truck systems. Its design ensures a snug fit in the designated groove, providing a consistent seal under various operating conditions. Unique characteristics may include enhanced flexibility for better sealing performance and resistance to wear and degradation over time.

Benefits of Using the Cummins 3535600 O Ring Seal

Utilizing the Cummins 3535600 O Ring Seal offers several advantages. It provides improved sealing efficiency, reducing the risk of leaks and ensuring that systems operate at optimal levels. Its durability and resistance to various operating conditions contribute to a longer service life, reducing the need for frequent replacements. Additionally, its reliable performance helps maintain the integrity of truck systems, contributing to overall vehicle safety and efficiency.

Installation Considerations

Proper installation of the Cummins 3535600 O Ring Seal is crucial for ensuring its effectiveness. Guidelines for installation include ensuring the groove is clean and free of debris before placing the O Ring. Careful handling is necessary to avoid damaging the O Ring during installation. It should be seated properly in the groove without twisting or pinching, which could compromise its sealing ability.

Troubleshooting Common Issues

Common issues with O Ring Seals include leaks or failure due to wear, improper installation, or exposure to incompatible chemicals. Troubleshooting steps involve inspecting the O Ring for signs of damage or deformation, ensuring it is correctly seated in the groove, and verifying that the materials it is exposed to are compatible with its composition. Replacement may be necessary if the O Ring is found to be damaged or worn.

Maintenance Tips

Regular maintenance of the Cummins 3535600 O Ring Seal can prolong its lifespan and ensure continued reliable performance. This includes periodic inspection for signs of wear or damage, cleaning the groove and surrounding areas to prevent contamination, and replacing the O Ring as part of routine system maintenance or when signs of degradation are observed.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a strong reputation in the commercial truck industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s extensive product range and history of excellence make it a trusted name in the industry 2.

Cummins O Ring Seal 3535600 Compatibility

The Cummins O Ring Seal part number 3535600 is designed to fit a variety of Cummins engines, ensuring a tight seal where needed to prevent leaks. This part is crucial for maintaining the integrity of the engine’s systems. Below is a detailed breakdown of the engines that this O Ring Seal is compatible with:

15N Series

- 15N CM2380

6C Series

- 6C8.3

- GTA8.3 CM558

B5.9 Series

- B5.9 G

- B5.9 GAS PLUS CM556

- ISB5.9G CM2180

B6.7 Series

- B6.7 G CMOH6.0 B125

- QSB6.7 CM850 (CM2850)

C Series

- C GAS PLUS CM556

- C8.3 G

G8.3 Series

- G8.3

ISB Series

- ISB5.9G CM2180

ISB/ISBE Series

- ISBE4 CM850

ISG Series

- ISG12 G CMOH6.0 G111

ISL Series

- ISL G CM2180

ISX Series

- ISX12 G CM2180 EJ

L8.9 Series

- L8.9G CMOH2.0 L125B

QSB Series

- QSB6.7 CM850 (CM2850)

- QSB7 CM2880 B117

QSC Series

- QSC8.3 CM850 (CM2850)

QSG Series

- QSG12/X12 CM2350 G110

QSL Series

- QSL9 G CM558

This O Ring Seal is engineered to fit snugly in various engine components, ensuring that the seal is effective and long-lasting. It is important to verify the specific application of the seal within the engine to ensure proper fitment and function.

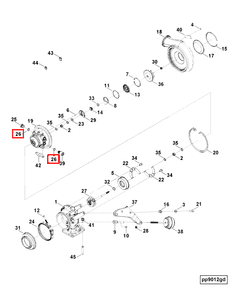

Role of Part 3535600 O Ring Seal in Engine Systems

The 3535600 O Ring Seal is an essential component in ensuring the integrity and efficiency of various engine systems. Its primary function is to create a reliable seal, preventing leaks and maintaining pressure within the system. Here’s how it integrates with the provided components:

Turbocharger Systems

In turbocharger applications, the O ring seal is often used in the turbocharger bearing housing and turbocharger core to seal moving parts and prevent oil leaks. It ensures that the lubricant stays within the housing, reducing friction and wear on the bearings.

Fuel Systems

For the fuel injection pump, the O ring seal is vital in maintaining fuel pressure and preventing leaks. It is commonly found in connections and fittings, ensuring that fuel delivery remains consistent and efficient.

Heat Exchanger Assemblies

In core assembly heat exchangers such as the 35G, 35W, 40, and 40W variants, the O ring seal plays a significant role in sealing the connections between the core assembly and the banjo connector screw. This ensures that the coolant or other fluids used in the heat exchange process do not leak, maintaining the efficiency of the heat transfer.

Plumbing and Fittings

In turbocharger plumbing and general engine installation kits, the O ring seal is used in various fittings such as the male union, plain adapter, and reducing adapter. These seals are essential for maintaining the integrity of the fluid pathways, whether they involve oil, coolant, or other fluids.

Protective and Assembly Components

The O ring seal is also found in the protective cover and various assembly kits including the assembly core and engine installation kit. Here, it ensures that environmental contaminants do not enter sensitive areas, and that internal pressures are maintained.

Miscellaneous Applications

In components like the threaded plug, the O ring seal provides a tight seal to prevent fluid or gas escape. This is particularly important in applications where pressure maintenance is key to system performance.

Overall, the 3535600 O Ring Seal is a versatile component that enhances the reliability and performance of various engine systems by ensuring secure, leak-proof connections.

Conclusion

The Cummins 3535600 O Ring Seal plays a critical role in maintaining the integrity and efficiency of commercial truck systems. By preventing leaks and ensuring proper system function, this part contributes to the overall safety and performance of the vehicle. Proper installation, regular maintenance, and understanding its applications across various engine components are essential for maximizing the benefits of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.