This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3679122 O Ring Seal is a component designed for use in commercial truck maintenance. It ensures the integrity of seals within various systems of commercial trucks, contributing to the overall efficiency and reliability of the vehicle 1.

Basic Concepts of O Ring Seals

O Ring Seals are circular rings, typically made from elastomers, that create a seal when compressed within a groove. They function by filling the space between mating surfaces, preventing the leakage of fluids and gases 2. O Ring Seals are widely used in mechanical systems due to their simplicity, effectiveness, and versatility in various applications.

Role of the 3679122 O Ring Seal in Truck Operation

The Cummins 3679122 O Ring Seal plays a specific role in the operation of commercial trucks by providing a reliable seal in critical areas. It is commonly placed within the engine or other systems where fluid or gas containment is necessary. Its function is to maintain the integrity of these seals, ensuring that fluids and gases remain contained within their designated pathways.

Key Features of the 3679122 O Ring Seal

The design and material characteristics of the Cummins 3679122 O Ring Seal are tailored to enhance its performance and durability in heavy-duty applications. It is constructed from materials that offer resistance to a wide range of fluids and temperatures, ensuring reliable operation under demanding conditions 3.

Benefits of Using the 3679122 O Ring Seal

The Cummins 3679122 O Ring Seal offers several advantages, including improved sealing efficiency, resistance to wear and tear, and compatibility with various fluids and temperatures. These benefits contribute to the overall reliability and performance of commercial trucks.

Troubleshooting Common Issues with O Ring Seals

Identifying and addressing typical problems associated with O Ring Seals, such as leaks, degradation, and improper installation, is important for maintaining the integrity of seals within commercial trucks. Regular inspection and proper installation techniques can help prevent these issues.

Maintenance Tips for O Ring Seals

Regular inspection, cleaning, and replacement of O Ring Seals are recommended to ensure optimal performance and longevity. Following manufacturer guidelines for maintenance can help extend the life of these seals and maintain the efficiency of the truck’s systems.

Installation Guidelines

Proper installation of the Cummins 3679122 O Ring Seal involves preparing the sealing surface and ensuring correct placement within the groove. Following step-by-step instructions for installation can help achieve a reliable seal and prevent common installation errors.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a commitment to quality and innovation, Cummins serves customers in approximately 190 countries and territories, providing reliable and efficient power solutions for various industries.

O Ring Seal 3679122 Compatibility with Cummins Engines

The O Ring Seal part number 3679122, manufactured by Cummins, is designed to fit seamlessly within the ISX CM570, ISX CM870, and ISX CM871 engines. This seal plays a role in maintaining the integrity of the engine’s hydraulic and lubrication systems by preventing leaks and ensuring that the system operates efficiently.

For the ISX CM570, ISX CM870, and ISX CM871 engines, the O Ring Seal 3679122 is engineered to fit precisely in areas where it is most needed. These engines, known for their robust performance and reliability, benefit from the seal’s ability to withstand high pressures and temperatures, ensuring that the engine’s internal components remain protected and operational.

In these engines, the seal is typically used in conjunction with various hydraulic and lubrication system components, ensuring that the engine’s performance is not compromised. The seal’s design allows it to adapt to the specific requirements of each engine model, providing a reliable barrier against leaks and contamination.

By integrating the O Ring Seal 3679122 into the ISX CM570, ISX CM870, and ISX CM871 engines, Cummins ensures that these engines maintain their high standards of performance and durability. The seal’s compatibility with these engines underscores Cummins’ commitment to providing high-quality components that enhance engine reliability and longevity.

Role of Part 3679122 O Ring Seal in Engine Systems

The O Ring Seal, identified by part number 3679122, is integral to the efficient operation of various engine components. It ensures that fluids and gases remain contained within their designated pathways, preventing leaks that could compromise engine performance and reliability.

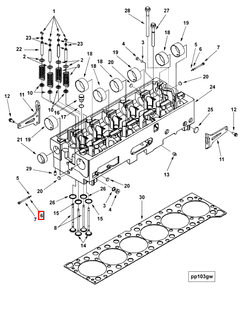

Integration with Cylinder Head

In the cylinder head, the O Ring Seal is positioned to create a tight seal around threaded plugs and other penetrations. This is essential for maintaining the integrity of the combustion chamber and ensuring that coolant and oil do not mix with combustion gases.

Function in Cylinder Top Level Assembly Head

Within the cylinder top level assembly head, the O Ring Seal plays a significant role in sealing connections between the head and the cylinder. This prevents any fluid leakage that could lead to reduced efficiency or potential engine damage.

Sealing the Head

The head of the engine, which includes various ports and passages, relies on the O Ring Seal to maintain pressure and prevent fluid escape. This is particularly important in high-performance engines where even minor leaks can have a substantial impact on overall performance.

Application in Cylinder RA

In the context of the cylinder RA (Rebuild Assembly), the O Ring Seal is used to ensure that all rebuilt components are properly sealed. This is vital for the longevity and reliability of the rebuilt engine, as it prevents contaminants from entering sensitive areas.

Enhancing Performance Parts

When it comes to performance parts, the O Ring Seal is often utilized to enhance the sealing capabilities of aftermarket components. This ensures that these parts perform optimally under high-stress conditions, contributing to the overall performance and durability of the engine.

Sealing Threaded Plugs

Threaded plugs, which are commonly used in engine blocks and heads to seal off unused passages, rely on the O Ring Seal to create a secure barrier. This is essential for maintaining the structural integrity of the engine and ensuring that fluids remain within their intended pathways.

Conclusion

The Cummins 3679122 O Ring Seal is a critical component in maintaining the efficiency and reliability of commercial trucks and Cummins engines. Its design and material characteristics ensure reliable operation under demanding conditions, contributing to the overall performance of the vehicle. Regular maintenance and proper installation are essential to maximize the benefits of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.