This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

O Ring Seals are elastomeric components designed to create a seal between two or more parts. They are widely used in mechanical systems to prevent leakage of fluids and gases. In commercial trucks, O Ring Seals are integral to maintaining the integrity of various systems, including fuel, hydraulic, and cooling systems. The basic principle behind O Ring Seals involves their ability to deform under compression, creating a tight seal that can adapt to dynamic and static applications. This flexibility ensures that the seal remains effective even under varying conditions and pressures 1.

Role of the 3680697 O Ring Seal in Truck Operations

The 3680697 O Ring Seal is specifically designed to play a vital role in the operational systems of trucks. It is commonly employed in systems where fluid and gas integrity is paramount, such as fuel injectors, hydraulic systems, and engine components. By ensuring a reliable seal, this O Ring Seal helps maintain the efficiency and performance of these systems. Its function is to prevent leaks, which can lead to system failures or reduced efficiency, thereby contributing to the overall reliability of truck operations 2.

Key Features of the 3680697 O Ring Seal

The 3680697 O Ring Seal is characterized by several key features that enhance its performance and durability in truck applications. It is typically made from high-quality elastomeric materials, which provide excellent resistance to various fluids and temperatures. The seal’s dimensions are precisely engineered to fit specific applications, ensuring a snug and effective seal. Additionally, any unique design characteristics, such as reinforced edges or specialized compounds, further contribute to its robustness and longevity in demanding environments 3.

Benefits of Using the 3680697 O Ring Seal

Utilizing the 3680697 O Ring Seal offers several advantages. Its improved sealing efficiency ensures that fluids and gases remain contained within the system, enhancing overall performance. The seal’s resistance to a wide range of fluids and temperatures makes it suitable for various truck applications. Moreover, its durability contributes to reduced maintenance needs and prolonged system life, providing cost-effective solutions for truck operators 4.

Installation and Maintenance Guidelines

Proper installation of the 3680697 O Ring Seal is crucial for ensuring optimal performance. It should be installed in a clean, lubricated groove to prevent damage and ensure a proper fit. Regular maintenance and inspections are recommended to prolong the life of the seal. This includes checking for signs of wear, deformation, or damage and replacing the seal as necessary to prevent leaks and system failures 5.

Troubleshooting Common Issues

Common problems associated with O Ring Seals in truck applications include leaks, wear, and failure due to exposure to extreme conditions. Troubleshooting these issues involves systematic approaches such as inspecting the seal for physical damage, ensuring proper installation, and verifying that the seal is compatible with the fluids and temperatures in the system. Recognizing signs of wear or failure early can help in taking prompt corrective actions, such as replacement or repair, to maintain system integrity 6.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a strong history of innovation and quality, Cummins has established itself as a trusted name in the commercial truck industry. The company’s commitment to excellence is evident in its manufacturing processes and the high-quality components it produces, such as the 3680697 O Ring Seal. Cummins’ focus on reliability and performance ensures that its products meet the demanding requirements of truck operators worldwide 7.

Cummins Engine Compatibility with Part 3680697 O Ring Seal

The O Ring Seal part number 3680697, manufactured by Cummins, is a critical component designed to ensure a secure seal in various engine systems. This seal is compatible with a range of Cummins engines, ensuring effective sealing and preventing leaks in critical areas.

ISX Series Engines

- ISX CM570

- ISX CM870

- ISX CM871

- ISX15 CM2250

- ISX15 CM2250 SN

- ISX15 CM2350 X101

The ISX series engines benefit from the O Ring Seal 3680697, which is essential for maintaining the integrity of the engine’s sealing systems. This seal is designed to fit precisely in the ISX engines, ensuring optimal performance and reliability.

QSX Series Engines

- QSX15 CM2250

- QSX15 CM2250 ECF

- QSX15 CM2350 X105

The QSX series engines also utilize the O Ring Seal 3680697. This seal is engineered to meet the specific sealing requirements of the QSX engines, providing a reliable barrier against leaks and ensuring the engine operates efficiently.

X15 Series Engines

- X15 CM2350 X116B

- X15 CM2350 X123B

- X15 CM2450 X134B

The X15 series engines incorporate the O Ring Seal 3680697, which is crucial for maintaining the sealing integrity of these engines. This seal is designed to fit the unique specifications of the X15 engines, ensuring that they perform reliably and efficiently.

Role of Part 3680697 O Ring Seal in Engine Systems

The Part 3680697 O Ring Seal is integral to the efficient operation of various engine components, ensuring optimal performance and longevity.

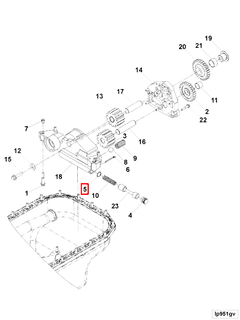

Lubricating Oil Pump

In the lubricating oil pump, the O Ring Seal is positioned to create a tight seal between the pump housing and the rotor assembly. This seal is essential for maintaining the pressure integrity of the oil as it is pumped through the engine. By preventing oil leaks, the O Ring Seal ensures that the oil reaches all necessary components without loss, thereby facilitating consistent lubrication and cooling.

Lubricating Pump Kit

When incorporated into a lubricating pump kit, the O Ring Seal plays a similar role. It ensures that the pump components remain sealed, allowing for efficient oil circulation. This is particularly important in maintaining the pump’s efficiency and reliability over time, as consistent sealing prevents contaminants from entering the oil system.

Overhaul Kit

In an overhaul kit, the O Ring Seal is often included to replace worn or damaged seals during engine maintenance. Its role here is to restore the seal integrity within the pump and other components, ensuring that the overhauled engine operates as efficiently as a new one. This is vital for maintaining the engine’s performance standards post-overhaul.

General Pump Applications

Across various pump applications within the engine system, the O Ring Seal is used to prevent oil leakage and maintain pressure. Whether in the primary lubricating oil pump or auxiliary pumps, the seal ensures that oil is delivered under the correct pressure to critical engine parts, enhancing overall engine efficiency and reliability.

Lubricating Oil System

Finally, within the broader lubricating oil system, the O Ring Seal contributes to the system’s integrity by ensuring that oil flows smoothly and under pressure to all lubricated components. This consistent oil flow is essential for reducing friction, wear, and heat within the engine, ultimately contributing to the engine’s durability and performance.

Conclusion

The 3680697 O Ring Seal plays a crucial role in maintaining the integrity and efficiency of various systems in commercial trucks. Its ability to create a reliable seal under varying conditions and pressures ensures that fluids and gases remain contained, preventing leaks and system failures. The seal’s compatibility with a range of Cummins engines further highlights its importance in ensuring optimal engine performance and longevity. Proper installation, maintenance, and timely replacement of this Cummins part are essential for sustaining the reliability and efficiency of truck operations.

-

Stone, Richard. Introduction to Internal Combustion Engines, Fourth Edition. Macmillan, 2012.

↩ -

Hilgers, Michael, and Wilfried Achenbach. Vocational Vehicles and Applications. Springer Vieweg, 2021.

↩ -

Reif, Konrad, ed. Diesel Engine Management Systems and Components. Springer Vieweg, 2014.

↩ -

Denton, Tom, and Hayley Pells. Automotive Technician Training Theory. Routledge, 2022.

↩ -

Cummins Inc. Service Manual (6454365).

↩ -

Hilgers, Michael, and Wilfried Achenbach. Vocational Vehicles and Applications. Springer Vieweg, 2021.

↩ -

Cummins Inc. Service Manual (6454365).

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.