This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

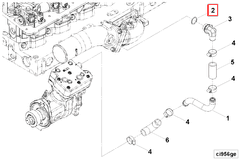

The Cummins 3682882 O Ring Seal is a critical component designed to maintain the integrity of seals in commercial truck operations. Its primary function is to prevent leaks and ensure system efficiency, contributing to the reliable operation of trucks, which is essential for the logistics and transportation industries.

Basic Concepts of O Ring Seals

O Ring Seals are circular rings, typically made from elastomers, that create a seal when compressed within a groove. They function by filling the space between mating surfaces, thus preventing the passage of fluids and gases. O Ring Seals are utilized across various mechanical systems, including engines, hydraulic systems, and pneumatic systems, due to their effectiveness in creating reliable seals under pressure 1.

Role of the 3682882 O Ring Seal in Truck Operations

The Cummins 3682882 O Ring Seal plays a crucial role in the operation of commercial trucks by ensuring the sealing of critical components within the truck’s systems. It is typically placed in grooves where two or more parts meet, such as in fuel systems or hydraulic components. Its function is to maintain a tight seal, which is essential for the efficient operation of these systems and for preventing leaks that could lead to system failure or inefficiency 2.

Key Features of the 3682882 O Ring Seal

The Cummins 3682882 O Ring Seal is characterized by several unique features that make it suitable for heavy-duty applications. These include its material composition, which is designed to withstand the harsh conditions encountered in commercial truck operations. The seal is crafted to offer durability and resistance to various operating conditions, such as extreme temperatures and exposure to chemicals, ensuring long-lasting performance 3.

Benefits of Using the 3682882 O Ring Seal

Utilizing the Cummins 3682882 O Ring Seal provides several advantages. These include enhanced sealing efficiency, which contributes to the overall performance of the truck’s systems. The seal’s durability leads to a longer service life, reducing the frequency of replacements. Additionally, its reliable performance enhances the overall system reliability, which is crucial for the uninterrupted operation of commercial trucks 4.

Troubleshooting Common Issues with O Ring Seals

Identifying and addressing typical problems associated with O Ring Seals, such as leaks or wear, is important for maintaining system integrity. Common issues can often be traced to improper installation, degradation due to environmental factors, or mechanical stress. Effective troubleshooting involves inspecting the seal for signs of wear or damage, ensuring proper installation, and replacing the seal if necessary to restore system functionality.

Maintenance Tips for O Ring Seals

Regular maintenance of O Ring Seals is key to ensuring optimal performance and longevity. This includes routine inspections for signs of wear, checking for proper seating within the groove, and ensuring that the seal is free from contaminants. Replacement guidelines suggest that seals should be inspected during regular maintenance intervals and replaced if any signs of degradation are observed to prevent potential system failures.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions. With a history rooted in innovation and quality, Cummins offers a comprehensive product range that includes engines, filtration, emissions solutions, and more. The company’s reputation in the commercial truck industry is built on its commitment to delivering reliable, efficient, and durable products that meet the demanding requirements of heavy-duty applications.

O Ring Seal Part 3682882 Compatibility with Cummins Engines

The O Ring Seal part 3682882, manufactured by Cummins, is designed to fit a variety of Cummins engines. This seal is essential for maintaining the integrity of fluid systems within the engine, ensuring that there are no leaks and that the engine operates efficiently.

ISX Series Engines

- ISX CM870

- ISX CM871

- ISX12 CM2350 X102

- ISX12/ISX11.9 CM2250

- ISX15 CM2250

- ISX15 CM2250 SN

- ISX15 CM2350 X101

The O Ring Seal part 3682882 is compatible with the ISX series engines, which are known for their robust performance and reliability. This seal is crucial for maintaining the fluid systems in these engines, ensuring that there are no leaks and that the engine operates efficiently.

ISZ Series Engines

- ISZ13 CM2150 Z105

This seal is also compatible with the ISZ13 CM2150 Z105 engine, providing a reliable seal for the fluid systems within this engine.

KTA Series Engines

- KTA38GC CM558

The O Ring Seal part 3682882 fits the KTA38GC CM558 engine, ensuring that the fluid systems within this engine are properly sealed and that there are no leaks.

QSK Series Engines

- QSK60G

This seal is compatible with the QSK60G engine, providing a reliable seal for the fluid systems within this engine.

QSX Series Engines

- QSX11.9 CM2250 ECF

- QSX15 CM2250 ECF

- QSX15 CM2350 X105

The O Ring Seal part 3682882 is compatible with the QSX series engines, ensuring that the fluid systems within these engines are properly sealed and that there are no leaks.

QSZ Series Engines

- QSZ13 CM2150 Z102

This seal is compatible with the QSZ13 CM2150 Z102 engine, providing a reliable seal for the fluid systems within this engine.

X Series Engines

- X15 CM2350 X116B

- X15 CM2350 X123B

- X15 CM2450 X134B

The O Ring Seal part 3682882 fits the X series engines, ensuring that the fluid systems within these engines are properly sealed and that there are no leaks.

This seal is designed to fit a wide range of Cummins engines, ensuring that the fluid systems within these engines are properly sealed and that there are no leaks. It is essential for maintaining the integrity of the engine and ensuring that it operates efficiently.

Role of Part 3682882 O Ring Seal in Engine Systems

The Part 3682882 O Ring Seal is integral to maintaining the integrity and efficiency of various engine systems. Its application spans across multiple components, ensuring that connections remain sealed and fluids or gases are contained effectively.

Adapter Connection

In the adapter connection, the O Ring Seal ensures a tight seal between mating surfaces, preventing leaks of fluids or gases that could compromise engine performance.

Compressor Air Inlet Arrangement and Plumbing

For the compressor air inlet arrangement and compressor air inlet plumbing, the O Ring Seal is used to secure connections, ensuring that air enters the compressor without any leaks, which is essential for optimal compressor operation and engine efficiency.

Exhaust Recirculation

In exhaust recirculation systems, the O Ring Seal helps maintain the seal at connection points, ensuring that recirculated exhaust gases are effectively managed and do not escape, which could lead to inefficiencies and increased emissions.

Lower Engine Gasket Kit and Set

Within the lower engine gasket kit and set, the O Ring Seal is employed to ensure that gaskets fit snugly and seal properly, preventing oil or coolant leaks that could damage engine components or reduce performance.

Male Union, Male Union Elbow, and Male Union Tee

For male union, male union elbow, and male union tee components, the O Ring Seal is critical in creating a secure connection that prevents fluid or gas leakage, ensuring the system operates as intended.

Overhaul Conversion Kit and Overhaul Kit

In overhaul conversion kits and overhaul kits, the O Ring Seal is used to replace worn seals, ensuring that all connections in the engine are leak-free post-overhaul, which is vital for restoring engine performance to its optimal state.

Plain Hose Coupling

The plain hose coupling utilizes the O Ring Seal to ensure a tight fit between the hose and the fitting, preventing leaks of fluids that could otherwise lead to system failure or reduced efficiency.

Radiator Plumbing

For radiator plumbing, the O Ring Seal ensures that coolant flows through the system without leaks, which is essential for maintaining proper engine temperature and preventing overheating.

HHP Ovhl Tur/Intl GSK

In the HHP overhaul turbine/international gasket set, the O Ring Seal is used to ensure that all gaskets seal properly, preventing leaks that could affect turbine performance and overall engine efficiency.

Thermostat Housing

The thermostat housing relies on the O Ring Seal to maintain a seal around the thermostat, ensuring that coolant flow is regulated properly and the engine operates within the desired temperature range.

Turbocharger Coolant and Oil Plumbing

In turbocharger coolant and oil plumbing, the O Ring Seal ensures that connections are leak-free, which is vital for maintaining the integrity of the turbocharger’s cooling and lubrication systems.

Turbocharger Plumbing

Finally, in turbocharger plumbing, the O Ring Seal is used to ensure that all connections are sealed, preventing leaks that could affect turbocharger performance and overall engine efficiency.

Conclusion

The Cummins 3682882 O Ring Seal plays a vital role in ensuring the integrity and efficiency of commercial truck and engine systems. Its unique features, compatibility with a wide range of Cummins engines, and the benefits it offers make it an essential component for maintaining reliable operation in the logistics and transportation industries.

-

Diesel Emissions and Their Control: Second Edition, Addy Majewski and Hannu Jaskelainen, SAE International, 2023

↩ -

High Speed Off-Road Vehicles, Bruce Maclaurin, Wiley, 2018

↩ -

Automobile Wheel Alignment and Wheel Balancing, R Mananathan, SAE International, 2022

↩ -

Automotive Maintenance: Light Repair, Rob Thompson, Cengage Learning, 2019

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.