3684269

O-Ring Seal

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3684269 O-Ring Seal is a specialized component designed for use in heavy-duty truck applications. Its purpose is to provide a reliable seal in various systems and components within these vehicles. The significance of this O-Ring Seal lies in its ability to maintain system integrity by preventing leaks and ensuring efficient operation, which is vital for the overall performance and longevity of heavy-duty trucks.

Basic Concepts of O-Ring Seals

O-Ring seals are elastomeric rings with a circular cross-section, designed to create a seal between two or more mating surfaces. They function by deforming under compression to fill the gap between the surfaces, thereby preventing the passage of fluids or gases. O-Ring seals are widely used in mechanical systems due to their simplicity, effectiveness, and versatility in various applications, including hydraulic, pneumatic, and engine systems 1.

Purpose of the Cummins 3684269 O-Ring Seal

The Cummins 3684269 O-Ring Seal plays a specific role in the operation of heavy-duty trucks by ensuring a secure seal in critical components and systems. It is commonly associated with fuel systems, where it helps maintain the integrity of fuel lines and connections. By preventing leaks, this O-Ring Seal contributes to the efficient and safe operation of the truck’s engine and fuel delivery system 2.

Key Features

The Cummins 3684269 O-Ring Seal is characterized by several key features that enhance its performance and durability. It is typically made from high-quality nitrile rubber, which offers excellent resistance to oils, fuels, and various chemicals commonly found in heavy-duty truck environments. The seal is designed with precise dimensions to ensure a proper fit and effective sealing. Additionally, its robust construction allows it to withstand high pressures and temperatures, making it suitable for demanding applications 3.

Benefits

Using the Cummins 3684269 O-Ring Seal provides several advantages. Its superior sealing efficiency helps prevent leaks, which can lead to system failures or inefficiencies. The seal’s longevity is enhanced by its durable material composition, reducing the need for frequent replacements. Furthermore, its resistance to various operating conditions ensures reliable performance in the challenging environments typical of heavy-duty truck operations.

Installation Considerations

Proper installation of the Cummins 3684269 O-Ring Seal is crucial for ensuring optimal performance and longevity. Guidelines for installation include ensuring that the mating surfaces are clean and free of debris to prevent damage to the seal. The seal should be lubricated with a compatible lubricant to facilitate easy installation and reduce the risk of damage. It is also important to avoid over-tightening fasteners, as this can distort the seal and compromise its effectiveness.

Troubleshooting Common Issues

Typical problems associated with O-Ring seals include leaks, extrusion, and degradation. To diagnose and resolve these issues, it is important to inspect the seal for signs of wear, damage, or deformation. If a leak is detected, the seal should be replaced. Extrusion, where the seal is forced out of its groove, may indicate excessive pressure or an improper fit, requiring adjustment or replacement. Degradation can be caused by exposure to incompatible fluids or extreme temperatures, necessitating the use of a more resistant material.

Maintenance Tips

Regular maintenance of the Cummins 3684269 O-Ring Seal involves routine inspections to check for signs of wear or damage. Cleaning the seal and its mating surfaces with a compatible solvent can help remove contaminants that may cause degradation. Replacement guidelines suggest that the seal should be inspected during regular maintenance intervals and replaced if any signs of wear or failure are detected. Proper storage in a cool, dry place can also extend the seal’s lifespan.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation for quality and innovation in the automotive and heavy-duty truck industry. The company’s product range includes a variety of engines, components, and systems designed to meet the demanding requirements of heavy-duty applications.

Cummins O-Ring Seal 3684269 Compatibility

The O-Ring Seal part number 3684269, manufactured by Cummins, is designed to fit a variety of Cummins engines. This seal is essential for maintaining the integrity of fluid systems and preventing leaks in the engines.

ISG12 CM2880 G107 and ISX CM871

The O-Ring Seal 3684269 is compatible with the ISG12 CM2880 G107 and ISX CM871 engines. These engines are known for their robust performance and reliability, often used in heavy-duty applications. The seal ensures that the fluid systems within these engines remain sealed, preventing any potential leaks that could compromise engine performance.

QSK95 CM2350 K113

This seal also fits the QSK95 CM2350 K113 engine. This engine model is recognized for its efficiency and power, commonly used in various industrial applications. The O-Ring Seal 3684269 plays a critical role in maintaining the seal in the fluid systems of this engine, ensuring it operates smoothly and efficiently.

QSG12/X12 CM2350 G110

The QSG12/X12 CM2350 G110 engine is another model where the O-Ring Seal 3684269 is applicable. This engine is designed for high-performance applications, and the seal helps in maintaining the necessary fluid integrity to support its demanding operational requirements.

X11 CM2670 X126B, X12 CM2670 X121B, X13 CM2670 X122B, and Z14 CM2670 Z103B

The O-Ring Seal 3684269 is also compatible with the X11 CM2670 X126B, X12 CM2670 X121B, X13 CM2670 X122B, and Z14 CM2670 Z103B engines. These engines are part of the Cummins X12 and Z-Series lineup, known for their versatility and reliability in various applications. The seal ensures that these engines maintain optimal fluid pressure and system integrity, contributing to their overall performance and longevity.

By ensuring a proper fit and seal, the O-Ring Seal 3684269 helps maintain the operational efficiency and reliability of these Cummins engines across different applications.

Role of Part 3684269 O-Ring Seal in Engine Systems

The Part 3684269 O-Ring Seal is integral to ensuring the integrity and efficiency of various engine systems. In the EGR Cooler Kit, it provides a reliable seal between components, preventing coolant or exhaust gas leaks that could compromise the system’s performance. Similarly, within the Exhaust Recirculation Cooler Kit, the O-ring ensures that the recirculated exhaust gases are effectively sealed, maintaining the desired flow rates and reducing emissions.

In the context of the Hose Kit, the O-ring is used at connection points to create a tight seal, which is essential for the conveyance of fluids without leakage. The Male Union components also benefit from the O-ring, as it ensures a secure connection between the union and the mating part, which is vital for systems where fluid dynamics and pressure are significant factors.

For the Mounting Kit, the O-ring plays a role in sealing any fluid passages that might be incorporated into the mounting structure, ensuring that the mounted components remain isolated from contaminants and maintain their operational parameters.

In the Parts Distribution Center Kit, where various components are assembled and tested, the O-ring is used to verify the sealing capabilities of different parts under simulated operating conditions.

The Repair Service Kit often includes O-rings as replacement parts for worn or damaged seals within an engine system, ensuring that repairs are effective and long-lasting.

In Tube Fitting Reducers, the O-ring is essential for adapting different sizes of tubing while maintaining a seal, which is particularly important in systems where precise fluid control is necessary.

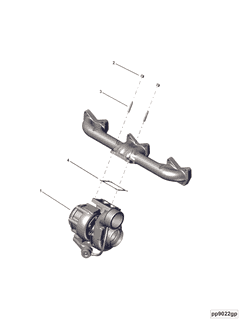

For the Turbocharger, the O-ring is used in various applications, such as within the Turbocharger Coolant Plumbing to prevent coolant leaks, and in the Turbocharger Gasket Kit to ensure that the turbocharger’s internal components are well-sealed against the high-pressure environment they operate in.

The Turbocharger Housing Kit and Turbocharger Housing Repair Kit both utilize O-rings to seal the housing against the turbocharger body, which is important for maintaining the efficiency and durability of the turbocharger.

In the Turbocharger Kit and Turbocharger Mounting Kit, O-rings are used to seal fluid passages and connections, ensuring that the turbocharger is mounted securely and operates within its designed parameters.

The Turbocharger Plumbing system relies on O-rings to seal connections and prevent leaks in the high-pressure and high-temperature environment of the turbocharger system.

Lastly, in the Upper Engine Gasket Kit, O-rings may be included to seal specific fluid passages or connections above the engine block, contributing to the overall sealing strategy of the engine’s upper components.

Conclusion

The Cummins 3684269 O-Ring Seal is a critical component in maintaining the integrity and efficiency of heavy-duty truck engine systems. Its robust construction, resistance to various operating conditions, and precise design make it suitable for demanding applications. Proper installation, regular maintenance, and timely replacement are essential to ensure the seal’s effectiveness and longevity, contributing to the overall performance and reliability of heavy-duty trucks.

-

Pedram Asef, Sanjeevikumar Padmanaban, and Andrew Lapthorn, Modern Automotive Electrical Systems (Wiley, 2022).

↩ -

Konrad Reif Ed, Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems (Springer Vieweg, 2014).

↩ -

R Mananathan, Automobile Wheel Alignment and Wheel Balancing (SAE International, 2022).

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.