3688221

O Ring Seal

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3688221 O Ring Seal is a component designed to ensure the integrity of seals within commercial truck systems. Its role is significant in maintaining the efficiency and reliability of truck operations by preventing leaks and ensuring proper system function 1.

Basic Concepts of O Ring Seals

An O Ring Seal is a type of gasket consisting of a ring of elastomer with a round cross-section. It creates a seal by being compressed in a groove, forming a barrier that prevents the passage of fluids and gases. O Ring Seals are widely used in mechanical systems due to their simplicity, effectiveness, and versatility in various applications 2.

Purpose of the 3688221 O Ring Seal in Truck Operations

This Cummins part is specifically utilized in commercial trucks to maintain seals in critical areas such as fuel systems, hydraulic systems, and engine components. It supports the operation of these systems by ensuring that fluids and gases remain contained, which is vital for the performance and safety of the vehicle 3.

Key Features of the 3688221 O Ring Seal

The design and material characteristics of the 3688221 O Ring Seal contribute to its effectiveness. It is made from materials that offer durability and resistance to a variety of fluids encountered in truck operations. Additionally, it can operate within a specific temperature range, ensuring reliable performance under varying conditions 4.

Benefits of Using the 3688221 O Ring Seal

Utilizing this part provides several advantages. It contributes to improved system efficiency by maintaining seals, reduces the need for frequent maintenance due to its durability, and enhances the reliability of truck operations by preventing leaks and ensuring system integrity 5.

Installation Considerations

Proper installation of the 3688221 O Ring Seal is crucial for its performance and longevity. Best practices include ensuring the groove is clean and free of debris before installation, using the correct amount of lubrication to facilitate seating, and avoiding over-compression which can lead to seal failure 6.

Troubleshooting Common Issues

Common problems with O Ring Seals, such as leaks or failures, can often be traced back to installation errors or environmental factors. Troubleshooting steps may include inspecting the seal and groove for damage, ensuring proper compression, and verifying that the seal material is compatible with the fluids and operating conditions 7.

Maintenance Tips

Regular maintenance of the 3688221 O Ring Seal is recommended to ensure continued performance. This includes periodic inspection for signs of wear or damage, cleaning the seal and groove as needed, and replacing the seal according to the manufacturer’s guidelines or when signs of degradation are observed 8.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a commitment to quality, Cummins serves commercial truck markets with a wide range of products designed to enhance performance, efficiency, and reliability 9.

Role of Part 3688221 O Ring Seal in Engine Systems

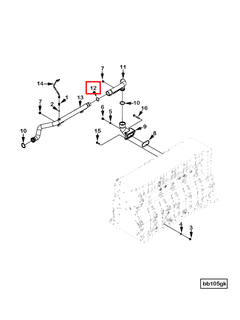

Plumbing

In the context of engine systems, the O Ring Seal (part 3688221) is integral to the plumbing setup. It ensures that fluid transfer within the engine remains leak-free. Positioned at connection points, the O Ring Seal prevents fluid leakage between pipes and fittings, maintaining the integrity of the fluid system. This is particularly important in high-pressure environments where even minor leaks can lead to significant issues 10.

Cylinder Block

Within the cylinder block, the O Ring Seal plays a key role in sealing various passages and connections. It is often used around coolant passages, oil galleries, and other critical areas where fluid dynamics are at play. By providing a tight seal, it helps in maintaining the pressure and flow of fluids, which is essential for the efficient operation of the engine. This seal is also vital in preventing cross-contamination between different fluids within the engine 11.

Water Transfer Tube

The O Ring Seal is employed in the water transfer tube to ensure that coolant circulation is uninterrupted and leak-free. It is placed at the junctions where the tube connects to other components, such as the cylinder block or radiator. This seal is essential for maintaining the coolant’s path, ensuring that the engine remains at optimal operating temperature. It also helps in preventing coolant loss, which could lead to overheating and potential engine damage 12.

Conclusion

The Cummins 3688221 O Ring Seal is a vital component in the maintenance and operation of commercial truck systems. Its role in preventing leaks, ensuring system integrity, and contributing to the efficiency and reliability of truck operations cannot be overstated. Proper installation, maintenance, and understanding of its function are key to leveraging the full benefits of this part.

-

Mohamed ElSayed PE, Fundamentals of Integrated Vehicle Realization, SAE International, 2017.

↩ -

David Crolla, Crolla Encyclopedia, Wiley, 2015.

↩ -

Paul Dempsey, Troubleshooting and Repairing Diesel Engines, 5th Edition, McGraw-Hill, 2018.

↩ -

Wolf-Henning Schneider, Pistons and Engine Testing, Springer Nature, 2016.

↩ -

Cummins Inc., Operation and Maintenance Manual for X15 CM2350 X114B - Efficiency Series, Bulletin Number 5411182.

↩ -

Mohamed ElSayed PE, Fundamentals of Integrated Vehicle Realization, SAE International, 2017.

↩ -

Paul Dempsey, Troubleshooting and Repairing Diesel Engines, 5th Edition, McGraw-Hill, 2018.

↩ -

Cummins Inc., Operation and Maintenance Manual for X15 CM2350 X114B - Efficiency Series, Bulletin Number 5411182.

↩ -

Cummins Inc., Company Overview, accessed [date].

↩ -

Mohamed ElSayed PE, Fundamentals of Integrated Vehicle Realization, SAE International, 2017.

↩ -

Wolf-Henning Schneider, Pistons and Engine Testing, Springer Nature, 2016.

↩ -

Cummins Inc., Operation and Maintenance Manual for X15 CM2350 X114B - Efficiency Series, Bulletin Number 5411182.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.