This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 3692406 O Ring Seal, manufactured by Cummins, is a component used in commercial trucks. It is part of the broader category of seals that are integral to maintaining system integrity in various fluid systems within these vehicles. Seals play a role in preventing leaks and ensuring the efficient operation of systems by maintaining pressure and containing fluids.

Basic Concepts of O Ring Seals

An O Ring Seal is a type of gasket consisting of a toroidal (doughnut-shaped) piece of elastomer. Its general construction involves a circular cross-section that allows it to create a seal when compressed between two or more mating surfaces. Materials commonly used for O Ring Seals include nitrile rubber, silicone, and fluorocarbon, each chosen for specific properties such as temperature resistance, chemical compatibility, and durability 1. The function of an O Ring Seal in fluid systems is to provide a barrier that prevents the escape of liquids or gases, thereby maintaining system pressure and efficiency.

Purpose of the 3692406 O Ring Seal in Truck Operations

This Cummins part is designed to serve a specific role in the operation of commercial trucks. It is associated with various systems or components where fluid containment is necessary. This includes but is not limited to, fuel systems, hydraulic systems, and cooling systems. By ensuring a tight seal, the 3692406 O Ring Seal contributes to the overall efficiency and reliability of these systems, playing a part in maintaining optimal performance under demanding conditions.

Key Features of the 3692406 O Ring Seal

The 3692406 O Ring Seal is characterized by its design and material properties, which are tailored for heavy-duty applications. Its construction allows for flexibility and resilience under pressure, while the material chosen for its manufacture offers resistance to the specific fluids and operating conditions it encounters. These features contribute to the seal’s effectiveness and durability, ensuring it can withstand the rigors of commercial truck operations.

Benefits of Using the 3692406 O Ring Seal

Utilizing the 3692406 O Ring Seal in commercial trucks offers several advantages. These include improved system efficiency due to effective fluid containment, enhanced longevity of the seal under demanding conditions, and increased reliability of the systems it serves. The seal’s design and material properties are optimized to provide these benefits, contributing to the overall performance and maintenance of the vehicle 2.

Installation Considerations

Proper installation of the 3692406 O Ring Seal is vital for ensuring its optimal performance and longevity. Guidelines for installation include ensuring the mating surfaces are clean and free of debris, using the correct amount of lubrication to facilitate seating, and avoiding over-compression of the seal. Common pitfalls to avoid during installation include damage to the seal during handling and improper seating, which can lead to leaks and reduced effectiveness.

Maintenance and Troubleshooting

Regular maintenance practices for the 3692406 O Ring Seal include periodic inspection for signs of wear or damage, such as cracks or deformation. Common issues that may arise include leaks, which can often be traced back to improper installation or environmental factors affecting the seal’s material. Replacement intervals will vary depending on the operating conditions and the specific system in which the seal is used, but regular checks can help identify when a replacement is necessary 3.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial vehicle industry. The company’s product range includes engines, powertrains, and related components, all designed to meet the demanding requirements of commercial and industrial applications. Cummins’ commitment to quality is evident in its rigorous testing and quality control processes, ensuring that its products, including the 3692406 O Ring Seal, meet the high standards expected in the industry.

Cummins O Ring Seal Part 3692406 Compatibility

The O Ring Seal part number 3692406, manufactured by Cummins, is designed to fit seamlessly with a range of Cummins engines. This part is crucial for ensuring a tight seal in various applications, thereby preventing leaks and maintaining system integrity.

Engine Compatibility

-

X15 CM2350 X123B and X15 CM2350 X116B: These engines share a similar design and architecture, making the O Ring Seal part 3692406 compatible with both. The seal fits into the designated areas where it needs to prevent fluid or gas leaks, ensuring optimal engine performance.

-

X15 CM2450 X134B: This engine, while slightly different in specifications, also accommodates the O Ring Seal part 3692406. The seal’s design allows it to adapt to the unique requirements of this engine model, providing a reliable barrier against leaks.

The O Ring Seal part 3692406 is engineered to meet the stringent demands of these engines, ensuring durability and effectiveness in various operating conditions. Its compatibility with the listed engines highlights its versatility and importance in maintaining engine efficiency and longevity.

Role of Part 3692406 O Ring Seal in Engine Systems

The 3692406 O Ring Seal is an essential component in ensuring the integrity and efficiency of various engine systems. Its application spans across multiple components, each playing a significant role in the overall performance of the engine.

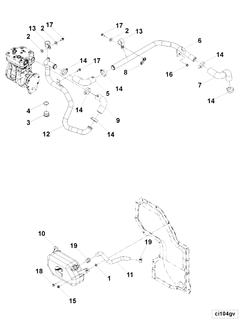

Compressor Air Inlet

In the compressor air inlet system, the 3692406 O Ring Seal is utilized to create a tight seal between the inlet and the compressor housing. This seal is vital for maintaining the pressure differential required for efficient air compression. By preventing air leaks, the O ring ensures that the compressor operates at optimal efficiency, thereby enhancing the engine’s performance.

Compressor Air Inlet Tube

The compressor air inlet tube is another area where the 3692406 O Ring Seal is employed. Here, it seals the connection points between the tube and other components, such as the compressor housing or the intercooler. This sealing function is important for maintaining the airflow integrity, which is essential for the proper functioning of the turbocharging system.

Plumbing

Within the engine’s plumbing system, the 3692406 O Ring Seal is used at various connection points to ensure that fluids, such as coolant or oil, do not leak. This is particularly important in high-pressure systems where even a small leak can lead to significant performance issues or damage. The O ring’s ability to withstand pressure and temperature variations makes it suitable for these applications.

Upper Engine Gasket Kit

The upper engine gasket kit often includes the 3692406 O Ring Seal to ensure a proper seal between the cylinder head and the intake manifold, or other upper engine components. This seal is important for maintaining the vacuum integrity within the intake system, which directly affects the engine’s airflow and, consequently, its performance.

Arrangement

In the overall arrangement of engine components, the 3692406 O Ring Seal plays a supportive yet significant role. It ensures that all sealed connections remain intact, contributing to the engine’s reliability and efficiency. Proper sealing prevents unwanted air or fluid leaks, which can lead to decreased performance or even engine damage over time.

The 3692406 O Ring Seal, through its applications in these various engine systems, underscores the importance of meticulous sealing in maintaining engine performance and reliability.

Conclusion

The 3692406 O Ring Seal is a critical component in the maintenance and efficiency of commercial truck engines. Its role in preventing leaks and ensuring system integrity cannot be overstated. Proper installation, maintenance, and understanding of its compatibility and application are essential for maximizing the performance and longevity of the engines it serves. Cummins’ commitment to quality and innovation is reflected in the design and functionality of this part, making it a reliable choice for heavy-duty applications.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.