3910517

O Ring Seal

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

This article provides an overview of the Cummins 3910517 O Ring Seal. It covers the basic concepts of O Ring Seals, the specific purpose and role of this Cummins part in truck operations, its key features, benefits, and maintenance suggestions.

Basic Concepts of O Ring Seals

An O Ring Seal is a mechanical gasket with a circular cross-section, used to create a seal between two or more parts 1. O Ring Seals work by being compressed within a groove, creating a seal that prevents the leakage of fluids or gases. They are commonly made from elastomers and are used in various applications due to their simplicity and effectiveness.

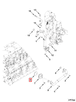

Purpose of the 3910517 O Ring Seal

The 3910517 O Ring Seal by Cummins is designed to provide a reliable seal in various components of commercial trucks. It plays a role in preventing leaks of fluids such as oil, coolant, and fuel, ensuring the efficient operation of the truck’s systems 2. This seal is particularly important in maintaining the integrity of pressurized systems and preventing contamination.

Key Features

The 3910517 O Ring Seal features include:

- Material: Typically made from durable elastomers to withstand high temperatures and pressures.

- Design: Circular cross-section to ensure even distribution of pressure and effective sealing.

- Compatibility: Designed to fit specific grooves and applications within Cummins engines and related systems.

Benefits

The benefits of using the 3910517 O Ring Seal include:

- Enhanced Sealing Performance: Provides a reliable barrier against leaks.

- Durability: Constructed to withstand harsh operating conditions.

- Easy Installation: Designed for simple replacement and maintenance.

Troubleshooting and Maintenance

Regular inspection of the 3910517 O Ring Seal is recommended to ensure its continued effectiveness. Signs of wear or damage, such as cracks or deformation, should be addressed promptly. Maintenance tips include:

- Regular Checks: Inspect the seal during routine maintenance intervals.

- Proper Installation: Ensure the seal is correctly seated in its groove to avoid leaks.

- Replacement: Replace the seal if any signs of wear or failure are detected to maintain system integrity.

Compatibility with Cummins Engines

The 3910517 O Ring Seal is compatible with a range of Cummins engines, including the ISB and QSB series, as well as other models such as the 15N CM2380 M104B, B6.7 CM2350 B135B, and QSK60 CM850 MCRS. This part ensures that these engines maintain their operational efficiency and reliability by preventing unwanted leaks and maintaining the necessary seals 3.

Role of 3910517 in Engine Systems

The 3910517 O Ring Seal is integral to the efficient operation of various engine systems by ensuring fluid and gas integrity within the components. Its application spans across multiple systems, enhancing performance and reliability.

Engine Cooling System

In the engine cooling system, the O Ring Seal is employed in the coolant heater starting mechanism to prevent leaks and maintain consistent coolant flow. It is also vital in the exhaust cooler water inlet tube and exhaust recirculation cooler kit, where it ensures that coolant circulates effectively without any loss, thus maintaining optimal engine temperature.

Exhaust Gas Recirculation (EGR) System

Within the EGR system, the O Ring Seal is used in the exhaust gas recirculation module support and the exhaust recirculation water plumbing. This ensures that exhaust gases are recirculated back into the engine efficiently, reducing emissions and improving fuel efficiency.

Turbocharger System

In the turbocharger system, the O Ring Seal is crucial in the turbocharger plumbing and the turbocharger kit. It secures connections in the exhaust recirculation cooler kit and the hardware kit, ensuring that the pressurized air from the turbocharger is delivered to the engine without any leaks, thus maximizing power output and engine performance.

Auxiliary Cooling System

For the auxiliary cooling system, the O Ring Seal is used in components such as the adapter connection and the exhaust cooler. This ensures that the auxiliary cooling system operates seamlessly, providing additional cooling when required and preventing overheating of critical engine components.

General Engine Components

The O Ring Seal is also found in general engine components such as the oil pan, lower engine gasket kit, and upper engine gasket kit. Here, it plays a role in maintaining the integrity of engine oil and other fluids, ensuring that they are contained within the system and do not leak, which could lead to engine damage.

Plumbing and Connections

In various plumbing applications throughout the engine systems, such as the plain hose coupling and the water transfer connection, the O Ring Seal ensures that all fluid pathways are sealed properly. This is essential for the consistent operation of the engine, whether it involves coolant, oil, or exhaust gases.

Cover Plates and Service Kits

The O Ring Seal is also utilized in cover plates and service kits to ensure that when these components are installed or replaced, they form a tight seal. This is particularly important in the overhaul kit and upper gasket set, where multiple seals need to be replaced to restore the engine to its optimal condition.

Conclusion

The Cummins 3910517 O Ring Seal is a versatile component that plays a significant role in maintaining the integrity and efficiency of various engine systems. Its proper installation and maintenance are essential for the overall performance and longevity of the engine.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.