3926047

O Ring Seal

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 3926047 O Ring Seal, manufactured by Cummins, is a critical component used in commercial trucks. It is part of the broader category of sealing solutions that maintain system integrity in various applications. Seals play a significant role in preventing leaks and ensuring the efficient operation of mechanical systems 1.

Basic Concepts of O Ring Seals

An O Ring Seal is a type of gasket that forms a seal by being compressed within a groove. It is typically made from elastomers, which are materials that can return to their original shape after deformation. Common materials include nitrile rubber, silicone, and fluorocarbon, each offering different properties such as resistance to chemicals, temperature, and compression set 2. The O Ring’s function is to create a barrier that prevents the passage of fluids or gases.

Role of the 3926047 O Ring Seal in Truck Operation

The 3926047 O Ring Seal is utilized in specific systems within commercial trucks, contributing to the operation of components that require a reliable seal. It is associated with systems where fluid or gas containment is necessary, and it helps maintain the integrity of these systems by preventing leaks.

Key Features of the 3926047 O Ring Seal

This Cummins part is characterized by its design and material composition. It is crafted to fit precisely within the designated groove, ensuring a snug fit that enhances sealing performance. The material used in its construction is selected for its ability to withstand the operating conditions it will encounter, including temperature variations and exposure to various fluids.

Benefits of Using the 3926047 O Ring Seal

Incorporating the 3926047 O Ring Seal into truck maintenance and repair offers several advantages. These include improved sealing efficiency, which can lead to better system performance and reduced maintenance costs. The seal’s durability and resistance to operating conditions contribute to its longevity, making it a cost-effective solution for commercial truck applications 3.

Installation Considerations

Proper installation of the 3926047 O Ring Seal is vital for its effectiveness. This involves preparing the sealing surface to ensure it is clean and free of imperfections. The O Ring must be seated correctly within the groove, and any torque specifications provided by the manufacturer should be followed to avoid over-tightening, which could damage the seal.

Troubleshooting Common Issues

Common problems with O Ring Seals, such as leaks or failure, can often be traced back to installation errors or degradation of the seal material. Troubleshooting steps may include inspecting the seal for signs of wear or damage, checking the groove for debris or imperfections, and ensuring that the seal was installed correctly.

Maintenance and Replacement

Regular maintenance and periodic replacement of the 3926047 O Ring Seal are recommended to ensure continued reliable operation. Factors to consider when deciding whether to replace the seal include signs of wear, exposure to harsh conditions, and the seal’s age. Following the manufacturer’s guidelines for maintenance can help extend the life of the seal and the systems it protects.

Cummins: A Brief Overview

Cummins Inc. is a well-established manufacturer in the commercial truck industry, known for its range of products and commitment to quality and innovation. The company has a history of producing reliable components that contribute to the efficiency and durability of commercial vehicles. Cummins’ reputation is built on its dedication to advancing technology and meeting the needs of its customers in the trucking sector.

Cummins Engine O Ring Seal 3926047 Compatibility

The O Ring Seal 3926047, manufactured by Cummins, is designed to fit a variety of Cummins engines. This seal is essential for maintaining the integrity of fluid systems within the engine, ensuring that there are no leaks and that the engine operates efficiently. Below is a detailed description of the engines that this O Ring Seal is compatible with, grouped where applicable for clarity.

4B3.9 Series

- 4B3.9

6B5.9 Series

- 6B5.9

B3.9 Series

- B3.9 G

B4.5 Series

- B4.5

B5.6 Series

- B5.6 CM2670 B152B

B5.9 Series

- B5.9

- B5.9 CM2670 B166C

- B5.9 GAS PLUS CM556

G5.9 Series

- G5.9

- G5.9 CM558

ISB Series

- ISB CM550

- ISB5.9 CM2880 B110

- ISB5.9 CM2880 B127

- ISB5.9 CM2880 B140

- ISB5.9 CM2880 B149

- ISB5.9G CM2180

QSB3.9 Series

- QSB3.9 30 CM550

QSB5.9 Series

- QSB5.9 30 CM550

- QSB5.9 44 CM550

- QSB5.9 CM2880 B115

- QSB5.9 CM2880 B139

- QSB5.9G

This O Ring Seal 3926047 is engineered to meet the specific requirements of these engines, ensuring a perfect fit and reliable performance. It is crucial for maintaining the seal in various components, such as fluid passages and connections, to prevent leaks and ensure optimal engine operation.

Role of Part 3926047 O Ring Seal in Engine Systems

In the context of engine systems, the 3926047 O Ring Seal is an essential component that ensures the integrity and efficiency of various engine assemblies. This seal is strategically placed in multiple engine configurations to prevent leaks and maintain pressure within the system.

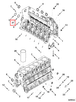

Integration with Engine Blocks

The O Ring Seal is utilized in several engine block configurations, including the Block 6-B Short, Short 4BT, Short 4BTA, Short 6BT, Short E2 Incent, and Short Euro1. In these blocks, the seal is positioned to create a tight barrier between mating surfaces, ensuring that coolant, oil, and other fluids do not escape. This is particularly important in the Cylinder Block and Cylinder Block Kit, where maintaining fluid levels is vital for engine performance and longevity.

Application in Short Blocks

In Short Blocks and Short Block Kits, the 3926047 O Ring Seal plays a significant role. It is installed in the Short 6-B Block, Short E1 180 Block, and Short E2 215/235 Block to seal critical junctions. These seals are also found in the Lower Engine Gasket Set and Full Engine Gasket Set, where they complement other gaskets to ensure a comprehensive seal across the engine.

Use in Cylinder and Crankshaft Assemblies

The seal is also integral to the Cylinder and Crankshaft and Bearings assemblies. In these components, it helps to maintain the necessary pressure and fluid levels, which are essential for the smooth operation of the engine. The seal’s placement around the crankshaft ensures that oil is retained, reducing friction and wear on moving parts.

Heat Exchanger Applications

In Heat Exchanger systems, the 3926047 O Ring Seal is used to prevent the leakage of coolant or other heat transfer fluids. This is crucial for maintaining the efficiency of the heat exchange process, which is fundamental to the engine’s cooling system.

Subset and LWR ENG GSK(SUND)

The seal is also a component of the Subset and LWR ENG GSK(SUND), where it ensures that the lower engine gasket set functions correctly. This is particularly important in maintaining the structural integrity of the engine and preventing fluid contamination.

Conclusion

The 3926047 O Ring Seal is a versatile component that enhances the functionality and reliability of various engine systems by providing essential seals at critical junctions. Its proper installation, maintenance, and timely replacement are crucial for the efficient operation of commercial trucks and the longevity of engine systems.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.