3945326

O Ring Seal

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3945326 O Ring Seal is a critical component designed for use in commercial trucks, ensuring the integrity of fluid and gas pathways across various systems. This part is essential for maintaining the efficiency and reliability of truck operations.

Basic Concepts of O Ring Seals

An O Ring Seal is a gasket made from a circular cross-section of elastomer, designed to create a seal between parts. Materials like nitrile rubber, silicone, and fluorocarbon are commonly used, each offering unique properties for specific applications 1. The primary function of an O Ring Seal is to maintain a tight seal under pressure, preventing leaks and protecting against contaminants.

Role of the 3945326 O Ring Seal in Truck Operation

This Cummins part ensures the integrity of seals in critical systems such as the engine and transmission. By preventing leaks, it helps maintain system pressure and efficiency, which is vital for the overall performance of the truck 2.

Key Features

Crafted from high-quality elastomer materials, the 3945326 O Ring Seal offers resistance to temperature variations and chemical exposure. Its design ensures a snug fit within its designated groove, providing a consistent seal. Specific durometer ratings ensure optimal flexibility and resilience, and compatibility with a wide range of fluids and gases 3.

Benefits

The 3945326 O Ring Seal enhances system efficiency by preventing leaks, reducing maintenance needs, and improving the reliability of the systems it supports. Its durable design ensures longevity and minimal degradation over time.

Troubleshooting and Maintenance

Common issues with O Ring Seals include leaks due to wear, exposure to incompatible fluids, or physical damage. Troubleshooting involves inspecting the seal for wear or damage, ensuring proper seating, and verifying compatibility with the intended fluids or gases. Maintenance practices include regular inspection, replacement according to manufacturer recommendations, and ensuring compatibility with the specific application.

About Cummins

Cummins Inc. is a global leader in power solutions, including engines, filtration, and emission solutions. With a century-long history, Cummins is renowned for its quality, reliability, and innovation in the commercial truck industry.

Compatibility with Cummins Engines

The 3945326 O Ring Seal is compatible with various Cummins engines, including the ISC, ISL, ISZ, QSC, and QSL series. It is crucial for maintaining the integrity of engine components by preventing leaks and ensuring a tight seal.

ISC Series Engines

- ISC CM2150

- ISC8.3 CM2250

ISL Series Engines

- ISL CM2150

- ISL CM554

- ISL9 CM2150 SN

- ISL9 CM2250

- ISL9.5 CM2880 L138

ISZ Series Engines

- ISZ13 CM2150 Z105

QSC and QSL Series Engines

- QSC9 CM2250/QSL9 CM2250

- QSL8.9 CM2150 L141

- QSL9 CM2250

- QSL9 CM2350 L102

- QSL9 CM850 (CM2850)

Role in Engine Systems

The 3945326 O Ring Seal is vital for the integrity and efficiency of various engine systems, including:

- Engine Brake Systems: Ensures airtight seals within the braking system.

- Tune-Up Kits: Maintains pressure integrity during tune-ups.

- Fasteners and Levers: Prevents fluid leaks and maintains structural integrity.

- Mounting and Alternator: Secures components and protects against environmental elements.

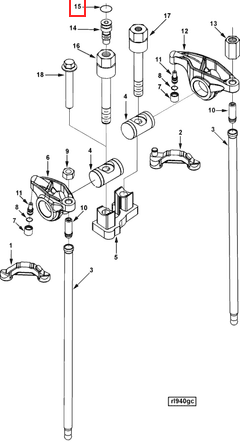

- Rocker Lever Assembly: Maintains seals at connection points for efficient operation.

Conclusion

The Cummins 3945326 O Ring Seal is a versatile and essential component for maintaining the efficiency and reliability of commercial truck engines. Its high-quality design and material properties ensure durability and minimal maintenance needs, contributing to the overall performance and longevity of the truck’s systems.

-

Ferrari, A., & Pizzo, P. (2022). Injection Technologies: Mixture Formation Strategies. SAE International.

↩ -

Bonnick, A. (2004). A Practical Approach to Motor Vehicle Engineering and Maintenance. Elsevier.

↩ -

Zhan, Q., Eben, S., & Deng, L. K. (2018). Automotive Heating Ventilation and Air Conditioning. Jones Bartlett Learning.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.