This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3957440 O Ring Seal is a component designed to ensure the integrity of seals within commercial truck systems. Its role is significant in maintaining the efficiency and reliability of truck operations by preventing leaks and ensuring proper system function 1.

Basic Concepts of O Ring Seals

An O Ring Seal is a type of gasket made from a circular cross-section of elastomer. It functions by creating a seal between two or more parts, typically in dynamic or static applications. The seal operates by deforming slightly when compressed between the mating surfaces, which creates a barrier that prevents the passage of fluids or gases 2.

Purpose of the Cummins 3957440 O Ring Seal

This Cummins part is specifically designed to play a role in the sealing mechanisms of truck systems. It is associated with components where fluid or gas containment is necessary, such as in fuel systems, hydraulic systems, or engine cooling systems. The seal ensures that these systems operate without leaks, which is vital for the overall performance and safety of the truck 3.

Key Features

This part is characterized by its material composition, typically a durable elastomer that can withstand a range of temperatures and pressures. Its dimensions are precisely engineered to fit specific applications, and its design features are tailored to enhance performance and durability in demanding environments.

Benefits of Using the Cummins 3957440 O Ring Seal

Utilizing this part offers several advantages. It provides improved sealing efficiency, which contributes to the reliable operation of truck systems. Its longevity is enhanced by its resistance to various environmental factors, including temperature fluctuations, chemical exposure, and mechanical stress.

Installation Considerations

When installing this part, it is important to prepare the mating surfaces to ensure they are clean and free of imperfections. Proper seating techniques should be employed to ensure the seal is correctly positioned and compressed, which is crucial for optimal performance and to prevent leaks.

Troubleshooting Common Issues

Common issues with O Ring Seals include leaks or failure due to wear, improper installation, or environmental factors. Diagnostic steps to address these issues may involve inspecting the seal for damage, ensuring correct installation, and assessing the condition of the mating surfaces.

Maintenance Tips

Routine maintenance practices can help prolong the life of the 3957440 O Ring Seal. Regular inspections should be conducted to check for signs of wear or damage. Conditions such as exposure to extreme temperatures or corrosive substances may necessitate replacement of the seal to maintain system integrity.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a strong reputation in the commercial truck industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction.

O Ring Seal Part 3957440 Compatibility with Cummins Engines

The O Ring Seal part 3957440, manufactured by Cummins, is designed to fit seamlessly with several of their engine models. This part is crucial for ensuring a tight seal in various applications, preventing leaks and maintaining the integrity of the engine’s operation.

ISB CM850

The ISB CM850 engine benefits from the O Ring Seal part 3957440, which is specifically engineered to fit its unique design and operational requirements. This seal plays a vital role in maintaining the engine’s performance by preventing unwanted fluid leaks.

QSB5.9 CM850

Similarly, the QSB5.9 CM850 engine also utilizes the O Ring Seal part 3957440. This part is integral to the engine’s sealing system, ensuring that all critical components remain sealed and operational. Its design allows for a precise fit, enhancing the engine’s reliability and efficiency.

QSC8.3 CM850 (CM2850)

The QSC8.3 CM850 (CM2850) engine incorporates the O Ring Seal part 3957440 as part of its sealing mechanism. This seal is essential for maintaining the engine’s performance and longevity by preventing leaks and ensuring that all components function as intended.

Role of Part 3957440 O Ring Seal in Engine Systems

The Part 3957440 O Ring Seal is integral to maintaining the integrity and efficiency of various engine systems. Its application spans across multiple components, ensuring optimal performance and longevity.

Lower Engine Gasket Kit

In the Lower Engine Gasket Kit, the O Ring Seal is employed to create a tight seal between moving and stationary parts. This prevents oil and coolant leaks, which are vital for maintaining proper lubrication and cooling within the engine. The seal ensures that these fluids remain contained, thereby preserving the engine’s operational efficiency and preventing potential damage from fluid loss.

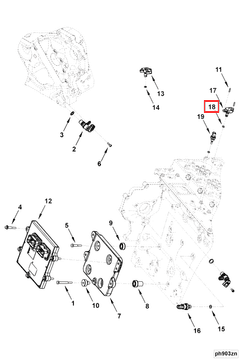

Module

When integrated into a Module, such as an Engine Control Module (ECM), the O Ring Seal plays a role in protecting sensitive electronic components from environmental factors. It seals connectors and interfaces, safeguarding against moisture, dust, and other contaminants that could impair the module’s functionality.

Engine Control

For Engine Control systems, the O Ring Seal is used in various sensors and actuators. It ensures that these components operate within specified parameters by maintaining consistent fluid and air pressures. This is particularly important in fuel injectors and turbochargers, where precise control is necessary for optimal engine performance.

Pressure Temperature Sensor

In Pressure Temperature Sensors, the O Ring Seal is crucial for accurate readings. By ensuring a secure seal around the sensor housing, it prevents external influences from affecting the sensor’s output. This results in more reliable data for the engine control unit, leading to better overall engine management.

Seal Kit

Within a Seal Kit, the O Ring Seal is often used to replace worn or damaged seals in various engine components. Its application here is straightforward yet essential for restoring the engine’s sealing integrity, which is fundamental for maintaining compression and preventing leaks.

Service Kit

In a Service Kit, the O Ring Seal is a common component used during routine maintenance. It helps in re-sealing areas that may have degraded over time, ensuring that the engine continues to operate efficiently after servicing. This proactive approach to maintenance can extend the engine’s lifespan and improve its reliability.

Upper Engine Gasket Kit

Finally, in the Upper Engine Gasket Kit, the O Ring Seal is used to ensure proper sealing in the cylinder head and valve cover areas. This is important for maintaining compression and preventing oil leaks, which are essential for the engine’s upper-end performance.

Conclusion

Overall, the Part 3957440 O Ring Seal is a versatile component that enhances the functionality and reliability of various engine systems. Its application across different engine components underscores its importance in maintaining the integrity and efficiency of commercial truck systems.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.