This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3971075 O Ring Seal is a component designed for use in heavy-duty truck maintenance and operation. It serves a specific function within the truck’s systems, contributing to the overall efficiency and reliability of the vehicle. Understanding its purpose and importance is key to maintaining the performance standards of heavy-duty trucks.

Basic Concepts of O Ring Seals

An O Ring Seal is a type of gasket consisting of a jointless, circular ring with a cross-section that is typically round. It functions by creating a seal between two or more parts, preventing the leakage of fluids or gases. O Ring Seals are widely used in mechanical systems due to their simplicity, effectiveness, and versatility in various applications 1.

Purpose of the 3971075 O Ring Seal in Truck Operation

This Cummins part plays a role in the truck’s systems by ensuring a tight seal in areas where fluid or gas transfer occurs. Its specific location and function within the truck’s systems are designed to maintain the integrity of the system it is part of, preventing leaks that could lead to inefficiencies or damage 2.

Key Features of the 3971075 O Ring Seal

The 3971075 is characterized by its material composition, which is selected for durability and resistance to the operating conditions it will encounter. Its design specifications are tailored to meet the demands of heavy-duty applications, ensuring it can withstand high pressures and temperatures without degrading 3.

Benefits of Using the 3971075 O Ring Seal

Utilizing this O Ring Seal offers several advantages, including enhanced sealing efficiency, which contributes to the overall performance of the truck. Its longevity and resistance to various operating conditions make it a reliable choice for maintaining the truck’s systems over time.

Troubleshooting Common Issues with O Ring Seals

Identifying and addressing typical problems associated with O Ring Seals, such as leaks or wear, is important for maintaining the truck’s systems. Effective maintenance involves inspecting the seals regularly and replacing them when signs of wear or damage are detected.

Maintenance Tips for O Ring Seals

Regular inspection and care of O Ring Seals are recommended to ensure optimal performance and longevity. Best practices for replacement and handling include using the correct tools and procedures to install new seals, ensuring they are properly seated and free from contaminants that could affect their performance.

Cummins: A Brief Overview

Cummins Inc. is a well-established company in the automotive and heavy-duty truck industry, known for its wide range of products and strong reputation for quality and reliability. The company’s history and product offerings reflect its commitment to innovation and excellence in the field of engine manufacturing and related components.

Role of Part 3971075 O Ring Seal in Engine Systems

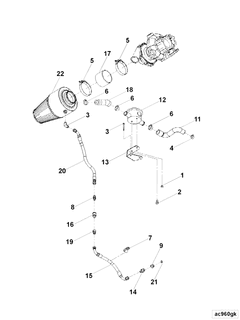

The 3971075 is integral to maintaining the efficiency and reliability of various engine components. In the air cleaner system, this O ring seal ensures a tight fit between the air cleaner housing and the intake manifold. This seal prevents air leaks, which can lead to inefficient air-fuel mixture and reduced engine performance.

Additionally, the O ring seal plays a significant role in the cleaner system by securing connections and joints. It ensures that contaminants are effectively filtered out before the air enters the engine, contributing to cleaner combustion and prolonged engine life.

By maintaining a secure seal in these systems, the 3971075 helps in optimizing engine performance, ensuring that air intake is consistent and free from impurities. This, in turn, supports overall engine health and efficiency.

Conclusion

The Cummins 3971075 O Ring Seal is a vital component in the maintenance and operation of heavy-duty trucks, particularly in the QSB5.9 CM850 and QSC8.3 CM850 (CM2850) engines. Its role in preventing leaks and ensuring system integrity contributes significantly to the efficiency, reliability, and longevity of these engines. Regular maintenance and inspection of this part are essential to ensure optimal engine performance and to prevent potential issues arising from seal failure.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.