This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3971076 O Ring Seal is a component designed to ensure the integrity of seals within commercial truck systems. Its role is significant as it contributes to the efficient operation and reliability of truck components by preventing leaks and maintaining system pressure 1.

Basic Concepts of O Ring Seals

An O Ring Seal is a type of gasket made from a circular cross-section of elastomer. It is designed to create a seal between two or more parts. The construction of an O Ring involves a single loop of material that is seated in a groove and compressed during assembly to create a seal. Materials commonly used for O Rings include nitrile rubber, fluorocarbon, and silicone, each offering different properties suitable for various applications 2. The function of an O Ring is to provide a barrier that prevents the passage of fluids or gases, ensuring the mechanical system operates as intended.

Purpose of the 3971076 O Ring Seal in Truck Operation

The 3971076 O Ring Seal is specifically designed to play a role in the sealing mechanisms of truck systems. It is associated with components where fluid or gas containment is necessary to maintain system efficiency. By providing a reliable seal, it helps in preserving the operational integrity of the associated systems or components 3.

Key Features of the 3971076 O Ring Seal

The 3971076 O Ring Seal is characterized by its precise design and material properties. It is crafted from materials that offer resilience against the operational stresses encountered in truck systems. Its unique characteristics may include resistance to certain chemicals, temperature extremes, and the ability to maintain elasticity over time, which enhances its sealing performance.

Benefits of Using the 3971076 O Ring Seal

Utilizing the 3971076 O Ring Seal offers several advantages. It provides improved sealing efficiency, which is vital for the consistent operation of truck systems. Its durability ensures long-term performance, and its resistance to various operating conditions makes it a reliable component in demanding environments.

Installation Considerations

Proper installation of the 3971076 O Ring Seal is important for its performance and longevity. Guidelines suggest ensuring the groove is clean and free of debris before installation. The O Ring should be lubricated to facilitate seating and avoid damage during assembly. Careful handling is recommended to prevent distortion or damage to the O Ring.

Troubleshooting Common Issues

Common problems with O Ring Seals can include leaks or failure to seal properly. Symptoms may involve fluid or gas escape, system pressure loss, or component malfunction. Potential causes can range from improper installation to material degradation. Recommended solutions may include re-seating the O Ring, replacing it if damaged, or addressing any underlying issues that may have contributed to the failure.

Maintenance Tips

Maintaining the 3971076 O Ring Seal involves regular inspection for signs of wear or damage. Cleaning the O Ring and its groove as part of routine maintenance can prevent contaminants from affecting its performance. Replacement should be considered if there are signs of degradation or if the O Ring no longer provides an effective seal.

Cummins Overview

Cummins Inc. is a corporation known for its diesel engines, related technologies, and power generation equipment. With a history of innovation and a broad product range, Cummins has established a reputation for quality and reliability in the commercial truck industry. The company’s commitment to excellence is reflected in its components, including the 3971076 O Ring Seal.

Role of Part 3971076 O Ring Seal in Engine Systems

The O Ring Seal, identified by part number 3971076, is integral to maintaining the efficiency and reliability of various engine components. Its primary function is to create a secure seal, preventing leaks and ensuring that systems operate within optimal parameters.

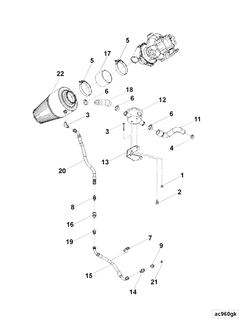

Air Cleaner Assembly

In the air cleaner assembly, the O Ring Seal is positioned to seal the connection between the air filter housing and the intake manifold. This seal is essential for maintaining the integrity of the air intake system. By preventing air leaks, it ensures that the engine receives a consistent and measured airflow, which is vital for combustion efficiency and overall engine performance.

Cleaner Components

Within the broader category of cleaner components, which may include fuel system cleaners or emissions control system components, the O Ring Seal plays a similar role. It ensures that fluids and gases are contained within their respective pathways, preventing cross-contamination and maintaining system efficiency. For instance, in fuel system cleaners, the seal prevents fuel leaks, which could lead to dangerous situations and decreased fuel efficiency.

Air System Integration

The O Ring Seal is also utilized in various air system integrations, such as turbochargers and intercoolers. In these applications, the seal helps maintain the pressure differentials necessary for efficient operation. For turbochargers, this means ensuring that compressed air is delivered to the engine without loss, enhancing performance. In intercoolers, the seal prevents coolant leaks, which could otherwise lead to overheating and reduced efficiency.

Overall, the consistent application of the O Ring Seal across these components underscores its importance in maintaining the functional integrity of engine systems.

Conclusion

The Cummins 3971076 O Ring Seal is a vital component in the operation and maintenance of commercial truck systems. Its role in preventing leaks, maintaining system pressure, and ensuring the efficient operation of engine components cannot be overstated. Proper installation, regular maintenance, and prompt troubleshooting of issues are essential to maximize the performance and longevity of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.