This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3977778 O Ring Seal is a component designed for use in heavy-duty truck maintenance and operation. Its purpose is to provide a reliable seal in various applications within the truck’s systems. The significance of this O Ring Seal lies in its ability to prevent leaks and ensure the efficient operation of the truck’s components.

Basic Concepts of O Ring Seals

An O Ring Seal is a type of gasket made from a doughnut-shaped piece of elastomer. Its general function is to create a seal between two or more parts. O Ring Seals are commonly made from materials such as nitrile, silicone, and fluorocarbon, each offering different properties suitable for various applications. They operate by deforming slightly when compressed between two surfaces, creating a seal that prevents the passage of fluids or gases 1.

Role of the 3977778 O Ring Seal in Truck Operation

The Cummins 3977778 O Ring Seal plays a specific role in the operation of a truck by ensuring the integrity of seals in various systems or components. It is often associated with fuel systems, hydraulic systems, and engine components where maintaining a seal is crucial for performance and safety 2.

Key Features of the 3977778 O Ring Seal

The Cummins 3977778 O Ring Seal is characterized by its design and material properties. It is crafted from high-quality elastomers that offer excellent resistance to oils, fuels, and other chemicals commonly found in truck operations. Its design ensures a snug fit in the designated grooves, enhancing its sealing capabilities.

Benefits of Using the 3977778 O Ring Seal

Using the Cummins 3977778 O Ring Seal offers several benefits. It provides improved sealing efficiency, which helps in maintaining system pressure and preventing leaks. Its durability ensures long-term performance even under harsh operating conditions. Additionally, its resistance to various chemicals and temperatures makes it suitable for a wide range of applications within heavy-duty trucks 3.

Installation Considerations

For optimal performance and longevity, the installation of the Cummins 3977778 O Ring Seal should follow specific guidelines. It is important to ensure the sealing surfaces are clean and free from debris. The O Ring should be lubricated before installation to facilitate easy insertion and to prevent damage. Careful handling is required to avoid distorting the O Ring, which could compromise its sealing ability.

Troubleshooting Common Issues

Common problems associated with O Ring Seals include leaks or failures, which can often be traced back to installation issues or environmental factors. Troubleshooting steps may involve inspecting the seal for signs of wear or damage, checking the condition of the sealing surfaces, and ensuring that the O Ring is the correct size and material for the application.

Maintenance and Replacement

Regular maintenance and timely replacement of the Cummins 3977778 O Ring Seal are recommended to prevent operational issues and ensure continued efficiency. Inspections should be conducted during routine maintenance checks, and the O Ring should be replaced if any signs of wear, damage, or leakage are detected.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the automotive and heavy-duty truck industry. Its product range includes engines, powertrain components, and aftermarket parts, all designed to meet the demanding requirements of various applications.

Role of Part 3977778 O Ring Seal in Engine Systems

The O Ring Seal, part number 3977778, is integral to the efficient operation and maintenance of various engine components. Its application spans across several key areas within the engine system, ensuring optimal performance and longevity of the engine.

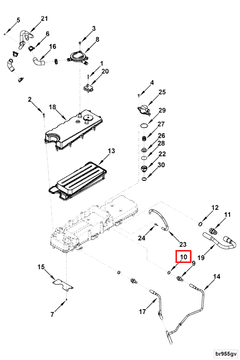

Compressor Air Inlet

In the compressor air inlet system, the O Ring Seal is positioned to create a tight seal between the inlet and the compressor housing. This seal is essential for maintaining the integrity of the air pressure within the system, preventing any air leaks that could compromise the efficiency of the compressor.

Valve Cover

When installed in the valve cover, the O Ring Seal plays a significant role in sealing the cover to the engine block. This seal is important for containing the engine’s lubrication system, specifically the oil that circulates within the valve train. A proper seal prevents oil leaks, which could lead to contamination of other engine components and a reduction in lubrication efficiency.

Breather and Crankcase

In the breather and crankcase systems, the O Ring Seal is used to seal the connections between these components and the engine block. This is particularly important in the crankcase, where the seal helps to contain crankcase gases and prevent them from escaping into the engine compartment.

Long Block

Within the long block assembly, the O Ring Seal is utilized in various connections, such as between the cylinder head and the engine block, or in the oil pan gasket area. Its role here is to ensure that all fluid pathways, including coolant and oil, are sealed properly.

Plain Hose Coupling

In applications involving plain hose couplings, the O Ring Seal is used to create a leak-proof connection between the hose and the engine component it is attached to. This is particularly important in systems where fluid dynamics are critical, such as fuel lines or coolant systems.

Conclusion

The Cummins 3977778 O Ring Seal is a versatile component that enhances the functionality and reliability of various engine systems. Its application across different components underscores its importance in maintaining the overall performance and efficiency of the engine.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.