This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3977779 O Ring Seal is a component designed for use in commercial truck maintenance. Its purpose is to provide a reliable seal in various applications within the truck’s systems, ensuring the integrity of fluid systems and preventing leaks. The significance of this O Ring Seal lies in its ability to maintain system efficiency and reliability, contributing to the overall performance and longevity of the truck 2.

Basic Concepts of O Ring Seals

O Ring Seals are circular elastomeric rings with a round cross-section, designed to create a seal between two or more mating surfaces. They function by deforming slightly when compressed, filling the gap between the surfaces and preventing the passage of fluids or gases. O Ring Seals are widely used in mechanical systems for their simplicity, effectiveness, and versatility in sealing applications 3.

Role of the 3977779 O Ring Seal in Truck Operation

The Cummins 3977779 O Ring Seal plays a specific role in the operation of a commercial truck by ensuring the integrity of seals in various fluid systems. It is typically located in areas where fluid transfer occurs, such as in the engine, transmission, or hydraulic systems. The seal’s function is to prevent leaks, maintain system pressure, and ensure the efficient operation of these systems 1.

Key Features of the 3977779 O Ring Seal

The Cummins 3977779 O Ring Seal is characterized by several unique features that enhance its performance and durability. These include its material composition, which is designed to withstand a range of temperatures and pressures, and its precise manufacturing tolerances, which ensure a proper fit and effective sealing. Additionally, the seal’s design allows it to accommodate minor misalignments between mating surfaces, further enhancing its reliability 2.

Benefits of Using the 3977779 O Ring Seal

Utilizing the Cummins 3977779 O Ring Seal offers several advantages. These include improved sealing efficiency, which helps maintain system pressure and prevent leaks. The seal’s durability and resistance to various operating conditions contribute to its longevity, reducing the need for frequent replacements. Furthermore, its design and material properties ensure reliable performance in demanding commercial truck applications 3.

Installation and Replacement Guidelines

Proper installation or replacement of the Cummins 3977779 O Ring Seal involves several steps. First, ensure the mating surfaces are clean and free of debris. Use appropriate tools to remove the old seal, taking care not to damage the surfaces. Inspect the new seal for any defects before installation. Lubricate the seal lightly to facilitate installation and prevent damage. Carefully place the seal into the groove, ensuring it is seated properly. Finally, reassemble the system and check for proper operation 1.

Troubleshooting Common Issues with O Ring Seals

Common issues with O Ring Seals include leaks, seal extrusion, and material degradation. To diagnose these problems, inspect the seal and mating surfaces for signs of wear, damage, or misalignment. Solutions may include replacing the seal, adjusting the system to reduce pressure or temperature, or modifying the design to better accommodate the seal. Regular maintenance and inspection can help prevent these issues 2.

Maintenance Tips for O Ring Seals

To ensure the longevity and effectiveness of the Cummins 3977779 O Ring Seal, routine maintenance practices are recommended. These include regular inspection of the seal and mating surfaces for signs of wear or damage, cleaning the surfaces to remove debris, and replacing the seal as needed. Additionally, monitoring system pressure and temperature can help identify potential issues before they lead to seal failure 3.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the commercial truck industry. The company’s product range includes engines, powertrain components, and aftermarket parts, all designed to meet the demanding requirements of commercial transportation 1.

Compatibility of O Ring Seal Part 3977779 with Cummins Engines

The O Ring Seal part number 3977779, manufactured by Cummins, is designed to ensure a secure seal in various engine applications. This seal is engineered to fit seamlessly with several Cummins engine models, providing essential sealing capabilities to maintain system integrity and performance.

ISB and ISBE Series

The ISB and ISBE series engines, including:

- ISB CM2150

- ISB/ISD4.5 CM2150 B119

- ISB/ISD6.7 CM2150 SN

- ISB6.7 CM2250

- ISBE CM2150

- ISBE4 CM850

are compatible with the O Ring Seal part 3977779. This seal is crucial in these engines for maintaining the integrity of the oil and fuel systems, preventing leaks and ensuring optimal engine performance.

ISX Series

The ISX series engines, which include:

- ISX CM570

- ISX CM870

- ISX CM871

- ISX12 CM2350 X102

- ISX12/ISX11.9 CM2250

- ISX15 CM2250

- ISX15 CM2250 SN

- ISX15 CM2350 X101

also utilize the O Ring Seal part 3977779. This seal is integral to the operation of these high-performance engines, ensuring that critical fluid systems remain sealed and that the engine operates efficiently.

ISZ Series

The ISZ series engine, specifically:

- ISZ13 CM2150 Z105

is another application for the O Ring Seal part 3977779. This seal is essential in maintaining the sealing integrity of the engine’s various systems.

QSB Series

The QSB series engines, including:

- QSB4.5 CM2250 EC

- QSB4.5 CM850(CM2850)

- QSB6.7 CM2250

- QSB6.7 CM2350 B105

- QSB6.7 CM850(CM2850)

- QSB6.7 M CM2250

- QSB7 CM2880 B117

are also compatible with the O Ring Seal part 3977779. This seal is vital in these engines for ensuring that the sealing of various components is maintained, which is crucial for the engine’s overall performance and longevity.

By ensuring a proper fit and function, the O Ring Seal part 3977779 plays a pivotal role in the maintenance and reliability of these Cummins engine models 2.

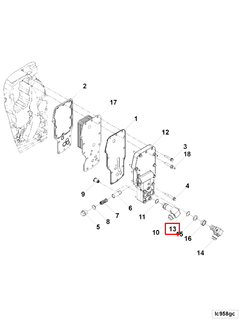

Role of Part 3977779 O Ring Seal in Engine Systems

The 3977779 O Ring Seal is integral to maintaining the efficiency and reliability of various engine systems by ensuring proper sealing and preventing leaks. Here’s how it interfaces with several key components:

Compressor Air Inlet Arrangement

In the compressor air inlet arrangement, the O Ring Seal ensures that the connection between the compressor and the air inlet is airtight. This prevents any air leaks that could reduce compressor efficiency and affect engine performance 3.

Valve Cover and Breather

When installed in the valve cover or breather system, the O Ring Seal helps maintain a sealed environment. This is essential for managing crankcase pressure and ensuring that any gases released do not escape into the atmosphere, thus preserving engine integrity 1.

Crankcase and Check Valve

In the crankcase and check valve applications, the O Ring Seal plays a role in maintaining the pressure balance within the crankcase. It ensures that the check valve operates efficiently by preventing any bypass of gases or fluids, which could lead to contamination or pressure issues 2.

Cooler and Engine Oil System

Within the engine oil cooler and related systems, the O Ring Seal is used to create a secure connection between various components. This is vital for maintaining the flow of lubricating oil without leaks, ensuring that the engine remains properly lubricated and cooled 3.

Drain and Remote Oil Filter

In the oil drain connection and remote oil filter setups, the O Ring Seal ensures that the drainage process is leak-free. This is important for both maintenance procedures and the overall reliability of the oil filtration system 1.

Fuel System Components

For fuel-related components such as the fuel filter, full flow oil filter head, fuel block connection, fuel control module, fuel filter head, fuel pump, and fuel transfer pump, the O Ring Seal is essential. It ensures that fuel lines and connections remain sealed, preventing fuel leaks and maintaining the integrity of the fuel system 2.

Long Block and Lubricating Oil Filter Head

In the long block and lubricating oil filter head, the O Ring Seal helps in creating a secure seal for various connections. This is important for the overall performance and durability of the engine, ensuring that all moving parts are properly lubricated 3.

Male Adapter Elbow and Male Union

For fittings like the male adapter elbow and male union, the O Ring Seal provides a reliable seal that withstands pressure and vibration. This is crucial for the durability and performance of the engine’s fluid systems 1.

Primer and Pump Systems

In the primer, fuel system, priming pump, fuel pump, and fuel transfer pump, the O Ring Seal ensures that the priming and pumping processes are efficient and leak-free. This is essential for the engine’s start-up procedure and ongoing operation 2.

Transfer Pump Support and Plain Hose Coupling

Finally, in the transfer pump support and plain hose coupling, the O Ring Seal ensures that all connections are secure and leak-proof. This contributes to the overall reliability and performance of the engine’s fluid transfer systems 3.

Conclusion

The Cummins 3977779 O Ring Seal is a critical component in maintaining the efficiency and reliability of commercial truck engines. Its role in preventing leaks, maintaining system pressure, and ensuring the proper operation of various engine systems cannot be overstated. Proper installation, regular maintenance, and timely replacement of this part are essential for the longevity and performance of the engine. By understanding the key features, benefits, and applications of the 3977779 O Ring Seal, technicians and fleet managers can ensure that their vehicles operate at peak efficiency and reliability.

-

Hiereth, Hermann, Peter Prenninger, and Klaus W Drexl. Charging the Internal Combustion Engine. Springer, 2010.

↩ ↩ ↩ ↩ ↩ ↩ -

Kershaw, John F. SAE International’s Dictionary for Automotive Engineers. SAE International, 2023.

↩ ↩ ↩ ↩ ↩ ↩ ↩ -

Dixon, John. Modern Diesel Technology Preventive Maintenance and Inspection. Delmar Cengage Learning, 2010.

↩ ↩ ↩ ↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.