4010489

O Ring Seal

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 4010489 O Ring Seal is a component designed to provide a reliable seal in various applications within commercial trucks. Its purpose is to prevent leaks and ensure the integrity of fluid systems, contributing to the overall efficiency and safety of truck operations.

Basic Concepts of O Ring Seals

An O Ring Seal is a type of gasket consisting of a jointless ring of elastomeric material used for sealing applications. It functions by creating a barrier that prevents the leakage of fluids and gases in mechanical systems. O Ring Seals are widely utilized in various industries due to their simplicity, effectiveness, and versatility in sealing applications 4.

Role of the 4010489 O Ring Seal in Truck Operations

The Cummins 4010489 O Ring Seal plays a specific role in the operation of a truck by ensuring the sealing of critical components within the truck’s systems. It is typically placed in areas where fluid dynamics are present, such as fuel systems, hydraulic systems, and engine compartments. Its function is to maintain the pressure and prevent the escape of fluids, which is vital for the proper operation of these systems 1.

Key Features

The Cummins 4010489 O Ring Seal is characterized by several key features that make it suitable for heavy-duty applications. It is composed of durable materials that can withstand high pressures and temperatures. Its design ensures a tight fit in the designated areas, providing a reliable seal. Additionally, the seal is engineered to resist various chemicals and environmental conditions, enhancing its longevity and performance in demanding truck operations 2.

Benefits

Using the Cummins 4010489 O Ring Seal offers several benefits. It provides improved sealing efficiency, which is crucial for maintaining system integrity and performance. The seal’s durability ensures long-term use without frequent replacements, reducing maintenance costs. Furthermore, its resistance to various operating conditions makes it a reliable component in the harsh environments typical of commercial truck operations 3.

Troubleshooting and Maintenance

Common issues associated with O Ring Seals include leaks due to wear, improper installation, or exposure to incompatible fluids. Troubleshooting these problems involves inspecting the seal for signs of damage, ensuring correct installation, and verifying compatibility with the system’s fluids. Regular maintenance practices, such as periodic inspection and replacement as needed, can help ensure the longevity and effectiveness of the Cummins 4010489 O Ring Seal 4.

Compatibility with Cummins Engines

The 4010489 O Ring Seal is compatible with a range of Cummins engines, providing a reliable barrier against leaks and ensuring optimal engine performance. Below is a detailed breakdown of the engines with which this O Ring Seal is compatible:

ISB and ISC Series

- ISB CM850

- ISC CM850

ISG12 Series

- ISG12 CM2880 G107

ISL9 Series

- ISL9 CM2150 SN

ISX Series

- ISX CM870

- ISX12 CM2350 X102

- ISX12/ISX11.9 CM2250

ISZ13 Series

- ISZ13 CM2150 Z105

QSX and QSZ Series

- QSX11.9 CM2250 ECF

- QSZ13 CM2150 Z101

- QSZ13 CM2150 Z102

X11, X12, and X13 Series

- X11 CM2670 X126B

- X12 CM2350 X119B

- X12 CM2670 X121B

- X13 CM2670 X122B

Z13 Series

- Z13 Z108G

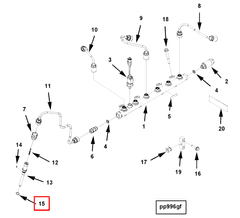

Role of Part 4010489 O Ring Seal in Engine Systems

The 4010489 O Ring Seal is an essential component in maintaining the integrity and efficiency of various engine systems. Its primary function is to provide a reliable seal in areas where fluid or gas transfer occurs, preventing leaks and ensuring optimal performance.

Cylinder Head

In the cylinder head, the O Ring Seal is utilized to seal connections between the head and the upper engine gasket kit. This ensures that combustion gases remain contained within the combustion chamber, contributing to efficient engine operation and preventing potential damage from gas leaks.

Fuel Systems HD XPI

Within the high-pressure fuel systems, specifically the HD XPI, the O Ring Seal plays a significant role in sealing the injector fuel supply connector. This prevents fuel leaks, which are not only hazardous but also detrimental to the efficiency of the fuel delivery system.

Injector and Injector Body

The O Ring Seal is integral in the assembly of the injector and injector body. It seals the connection points, ensuring that fuel is delivered under precise pressure without any leakage. This is vital for the injector’s performance and the overall fuel efficiency of the engine.

Injector Nozzle and Injector Plumbing

In the injector nozzle and plumbing, the O Ring Seal ensures that the fuel path remains sealed. This is important for maintaining the correct fuel pressure and preventing any fuel from escaping, which could lead to inefficient combustion and increased emissions.

Module, Engine Control, and Plumbing

The O Ring Seal is also used in the module, engine control, and various plumbing connections throughout the engine. Its role here is to maintain the integrity of fluid and gas pathways, ensuring that the engine control module receives accurate data from sensors and that all systems operate within their designed parameters.

Pressure Temperature Sensor

In the pressure temperature sensor, the O Ring Seal ensures that the sensor housing is sealed against the engine block or manifold. This prevents any external contaminants from affecting the sensor’s readings and ensures accurate data is sent to the engine control module for optimal engine management.

XPI JV System Cummins HD

Finally, in the XPI JV System for Cummins HD engines, the O Ring Seal is used in various connections to maintain the high-pressure integrity of the fuel system. This is particularly important in high-performance engines where precise fuel delivery is essential for power output and efficiency.

Conclusion

In summary, the Cummins 4010489 O Ring Seal is a fundamental component in a variety of engine systems, ensuring seals are maintained in critical areas to prevent leaks, maintain pressure, and ensure the accurate functioning of engine components. Its compatibility with a wide range of Cummins engines, coupled with its durable and reliable design, makes it an essential part for maintaining the efficiency and safety of commercial truck operations.

-

Bosch, R. (2014). Bosch Automotive Handbook 9th Edition. Robert Bosch GmbH.

↩ -

Ling, F. F. (2011). The Automotive Body. Springer Science.

↩ -

Han, Z. (2022). Simulation and Optimization of Internal Combustion Engines. SAE International.

↩ -

Lejda, K., & Wos, P. (2012). Internal Combustion Engines. InTech.

↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.