4010635

O Ring Seal

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 4010635 O Ring Seal is a component designed for use in commercial trucks. It serves a specific function within the truck’s mechanical systems, ensuring the integrity of seals in various applications. Manufactured by Cummins Inc., a well-established name in the commercial vehicle industry, this O Ring Seal is engineered to meet the demanding requirements of heavy-duty operations 1.

Basic Concepts of O Ring Seals

O Ring Seals are circular rings, typically made from elastomers, that create a seal when compressed within a groove. They function by filling the space between mating surfaces, preventing the leakage of fluids or gases. O Ring Seals are widely used in mechanical systems due to their simplicity, effectiveness, and versatility in sealing applications 2.

Purpose of the 4010635 O Ring Seal in Truck Operations

The Cummins 4010635 O Ring Seal plays a role in the operation of commercial trucks by providing a reliable seal in critical areas, such as within the engine or other systems where fluid or gas containment is necessary. Its placement is strategic, ensuring that it can effectively prevent leaks under various operating conditions, thus contributing to the overall efficiency and reliability of the truck 3.

Key Features of the 4010635 O Ring Seal

The design and material characteristics of the Cummins 4010635 O Ring Seal are tailored to enhance its performance and durability in heavy-duty applications. It is made from materials that offer resistance to a wide range of fluids and temperatures, ensuring it can withstand the harsh conditions encountered in commercial truck operations. Its design allows for optimal compression and sealing efficiency, contributing to its longevity and reliability.

Benefits of Using the 4010635 O Ring Seal

Utilizing the Cummins 4010635 O Ring Seal offers several advantages. It provides improved sealing efficiency, reducing the risk of leaks and ensuring the integrity of the system it is part of. Its resistance to wear and tear, along with its compatibility with various fluids and temperatures, makes it a robust choice for heavy-duty applications. Furthermore, its design contributes to ease of installation and maintenance, enhancing its appeal for use in commercial trucks.

Installation and Maintenance Tips

Proper installation of the Cummins 4010635 O Ring Seal is key to ensuring its optimal performance. It should be carefully placed within the designated groove, ensuring it is not twisted or damaged during the process. Regular inspection and maintenance are recommended to prolong its lifespan. This includes checking for signs of wear or damage and replacing the seal as necessary to maintain the system’s integrity.

Troubleshooting Common Issues

Typical problems associated with O Ring Seals, such as leaks or failures, can often be traced back to installation errors or environmental factors. Diagnosing these issues involves a thorough inspection of the seal and its surrounding components. Resolving these issues may require reinstallation of the seal, ensuring it is correctly positioned, or replacing it if it has been compromised.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a history of innovation and a commitment to quality, Cummins has established a strong reputation in the commercial vehicle industry. Its product range is designed to meet the needs of various applications, from on-highway to off-highway and industrial uses, ensuring reliability and performance across the board.

Cummins O Ring Seal 4010635 Compatibility

The Cummins O Ring Seal part number 4010635 is designed to fit a variety of Cummins engines, ensuring a secure seal in critical areas. This seal is essential for maintaining the integrity of the engine’s systems by preventing leaks and ensuring proper fluid containment.

ISC Series Engines

The 4010635 O Ring Seal is compatible with several ISC series engines, including:

- ISC CM2150

- ISC CM554

- ISC CM850

- ISC8.3 CM2250

These engines benefit from the seal’s ability to provide a tight fit, crucial for maintaining oil and coolant pathways.

ISL Series Engines

The ISL series engines also utilize the 4010635 O Ring Seal, including:

- ISL CM2150

- ISL CM554

- ISL9 CM2150 SN

- ISL9 CM2250

- ISL9.5 CM2880 L138

This seal ensures that the ISL engines operate efficiently by preventing leaks in high-pressure areas.

QSC Series Engines

The QSC series engines that are compatible with the 4010635 O Ring Seal include:

- QSC8.3 CM554

- QSC8.3 CM850 (CM2850)

- QSC9 CM2250 / QSL9 CM2250

These engines rely on the seal to maintain fluid integrity and prevent contamination.

QSL Series Engines

The QSL series engines that use the 4010635 O Ring Seal are:

- QSL8.9 CM2150 L141

- QSL9 CM2250

- QSL9 CM2350 L102

- QSL9 CM554

- QSL9 CM850 (CM2850)

This seal is critical for these engines to ensure that all fluid systems remain sealed and operational.

By providing a reliable seal, the Cummins O Ring Seal 4010635 is integral to the performance and longevity of these engines, ensuring they operate at peak efficiency.

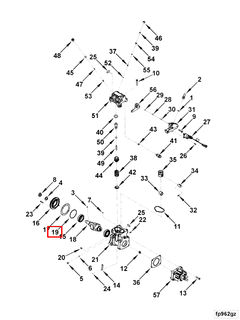

Role of Part 4010635 O Ring Seal in Engine Systems

The part 4010635 O Ring Seal is integral to the functionality and efficiency of various engine components. Its primary role is to ensure a tight seal, preventing leaks and maintaining system integrity.

Cam Housing and Cam Housing Module

In the cam housing and cam housing module, the O Ring Seal is positioned to create a secure seal between mating surfaces. This prevents any potential oil or fuel leaks that could occur due to vibrations or pressure fluctuations within the engine. The seal ensures that the lubrication system remains efficient, contributing to the overall performance and longevity of the cam housing components.

Fuel Injection Pump and Fuel Pump

For the fuel injection pump and fuel pump, the O Ring Seal is essential in maintaining the precise fuel delivery required for optimal engine operation. It seals the connections between the pump body and other components, ensuring that fuel is delivered without any loss or contamination. This is particularly important in high-pressure fuel systems where even minor leaks can lead to significant performance issues.

Fuel Pump Assembly and Fuel Pump Body

In the fuel pump assembly and fuel pump body, the O Ring Seal plays a role in maintaining the integrity of the fuel path. It ensures that fuel flows smoothly from the pump to the injectors without any external leakage. This is vital for consistent fuel pressure and efficient engine combustion.

Fuel Pump Kit and Fuel Pump Mounting

When installed in a fuel pump kit or during fuel pump mounting, the O Ring Seal contributes to the overall reliability of the fuel system. It prevents any fuel from escaping at connection points, which is essential for maintaining the correct fuel pressure and ensuring that the engine operates within specified parameters.

XPI JV Components and XPI JV System Cummins MR

In the XPI JV components and XPI JV System Cummins MR, the O Ring Seal is used to seal various high-pressure connections. This is important for the system’s ability to deliver fuel at the required pressures for modern diesel engines. The seal helps in maintaining the system’s efficiency and reliability, which is crucial for the engine’s performance and emissions control.

Conclusion

The Cummins 4010635 O Ring Seal is a critical component in the maintenance and operation of commercial trucks and various Cummins engines. Its design and material properties ensure it can withstand the demanding conditions of heavy-duty applications, providing reliable sealing and contributing to the overall efficiency and reliability of the systems it is part of. Proper installation, regular maintenance, and timely replacement are key to maximizing its performance and lifespan.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.