4010643

O Ring Seal

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

Minimum Quantity 2

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 4010643 O Ring Seal, manufactured by Cummins, is designed to enhance the reliability and efficiency of commercial truck operations. Cummins produces this seal to meet the demanding requirements of heavy-duty applications. The O Ring Seal is integral to maintaining the integrity of various systems within commercial trucks, ensuring they operate smoothly and efficiently.

Basic Concepts of O Ring Seals

An O Ring Seal is a type of gasket consisting of a jointless ring of elastomeric material used for sealing applications. Its primary function in mechanical systems is to create a barrier that prevents the leakage of fluids or gases. O Ring Seals operate by being compressed between two or more mating surfaces, which creates a seal that is both pressure and temperature resistant. This makes them suitable for a wide range of applications, including those found in commercial trucks 1.

Purpose of the 4010643 O Ring Seal in Truck Operations

The 4010643 O Ring Seal plays a specific role in the operation of commercial trucks by ensuring the integrity of seals in various systems and components. It is typically associated with fuel systems, hydraulic systems, and engine components where maintaining a tight seal is crucial for performance and safety. By preventing leaks, the seal contributes to the efficient operation of these systems, ensuring that fluids and gases remain contained within their designated pathways.

Key Features of the 4010643 O Ring Seal

The design and material characteristics of the 4010643 O Ring Seal are tailored to meet the rigorous demands of heavy-duty truck environments. Made from high-quality elastomeric compounds, this seal is engineered to withstand extreme temperatures, pressures, and chemical exposures. Its durability is enhanced by precise manufacturing processes that ensure consistent dimensions and surface finish, critical for effective sealing performance 2.

Benefits of Using the 4010643 O Ring Seal

Utilizing the 4010643 O Ring Seal offers several advantages in commercial truck applications. These include improved sealing performance, which leads to enhanced system efficiency and reduced risk of leaks. The seal’s longevity is another benefit, as its robust construction allows it to maintain its integrity over extended periods, even under harsh operating conditions. Additionally, its resistance to various environmental factors ensures reliable performance across different applications 3.

Installation and Maintenance Guidelines

Proper installation of the 4010643 O Ring Seal is vital for its effective performance. It should be installed in clean, undamaged grooves to ensure a proper fit and seal. Regular maintenance practices, such as periodic inspection for signs of wear or damage, are recommended to ensure the continued effectiveness of the seal. Replacement should be considered if any degradation is observed to prevent potential system failures.

Troubleshooting Common Issues

Common issues with O Ring Seals in truck applications may include leaks, which can be caused by improper installation, wear and tear, or exposure to incompatible fluids. Diagnostic steps should involve inspecting the seal and its mating surfaces for damage or misalignment. Remedial actions may include cleaning the surfaces, ensuring proper installation techniques are used, or replacing the seal if necessary.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the commercial truck industry. Its product range is designed to meet the needs of various applications, ensuring optimal performance and efficiency in demanding environments.

O Ring Seal 4010643 Compatibility with Cummins Engines

The O Ring Seal part number 4010643, manufactured by Cummins, is a critical component in ensuring the integrity and efficiency of various engine systems. This seal is designed to fit seamlessly into multiple engine configurations, providing a reliable barrier against leaks and maintaining system pressure.

ISB Series Engines

The ISB series engines, including the ISB, ISB CM2150, ISB CM850, ISB/ISD4.5 CM2150 B119, ISB/ISD6.7 CM2150 SN, ISB6.7 CM2250, ISB6.7 CM2350 B101, and ISBE CM2150, all benefit from the O Ring Seal 4010643. This seal is particularly important in these engines for maintaining the seal in fuel injectors and other critical areas.

ISBE Series Engines

The ISBE4 CM850 engine also utilizes the O Ring Seal 4010643. This seal is essential for ensuring that the engine’s fuel system remains leak-free, which is crucial for maintaining optimal performance and efficiency.

ISC Series Engines

The ISC CM2150, ISC CM850, and ISC8.3 CM2250 engines are designed to incorporate the O Ring Seal 4010643. This seal is vital for preventing leaks in the engine’s fuel and lubrication systems, ensuring that the engine operates smoothly and efficiently.

ISD Series Engines

The ISD4.5 CM2220 D108 engine requires the O Ring Seal 4010643 to maintain the integrity of its fuel system. This seal is crucial for preventing leaks and ensuring that the engine’s performance is not compromised.

ISF Series Engines

The ISF2.8 CM2220 F129 and ISF3.8 CM2220 AN engines both utilize the O Ring Seal 4010643. This seal is essential for maintaining the seal in the engine’s fuel system, ensuring that the engine operates efficiently and reliably.

ISL Series Engines

The ISL CM2150, ISL G CM2180, ISL9 CM2150 SN, ISL9 CM2250, and ISL9.5 CM2880 L138 engines all incorporate the O Ring Seal 4010643. This seal is crucial for maintaining the seal in the engine’s fuel system, ensuring that the engine operates smoothly and efficiently.

ISM Series Engines

The ISM CM570/870, ISM CM876, and ISM11 CM876 SN engines require the O Ring Seal 4010643 to maintain the integrity of their fuel systems. This seal is essential for preventing leaks and ensuring that the engine’s performance is not compromised.

ISX Series Engines

The ISX12/ISX11.9 CM2250 and ISX15 CM2250 engines both utilize the O Ring Seal 4010643. This seal is crucial for maintaining the seal in the engine’s fuel system, ensuring that the engine operates efficiently and reliably.

Role of Part 4010643 O Ring Seal in Engine Systems

The O Ring Seal, identified by part number 4010643, is an essential component in ensuring the integrity and efficiency of various engine systems. Its application spans across multiple areas within the engine, contributing to the overall performance and reliability of the engine.

Turbocharger System

In the turbocharger system, the O Ring Seal is utilized to create a tight seal between the turbocharger and its housing. This seal is vital for maintaining the pressure differentials necessary for efficient turbocharging. By preventing leaks, the O Ring Seal ensures that the compressed air delivered to the engine cylinders is at the optimal pressure, enhancing combustion efficiency and power output.

Cylinder Block and Gear Housing

Within the cylinder block and gear housing, the O Ring Seal plays a significant role in sealing the interfaces between various components. In the cylinder block, it is used to seal the connections between the block and the cylinder sleeves or liners, preventing coolant or oil leaks that could compromise engine performance. In the gear housing, the O Ring Seal ensures that lubricants remain contained, providing consistent lubrication to the moving parts and reducing wear and tear.

Service Coupling Assemblies

For the service coupling 2008 and 2009 assemblies, the O Ring Seal is employed to maintain the seal integrity between the coupling components. This is particularly important in ensuring that the coupling operates smoothly without any fluid leaks, which could lead to decreased efficiency or potential failure of the coupling mechanism.

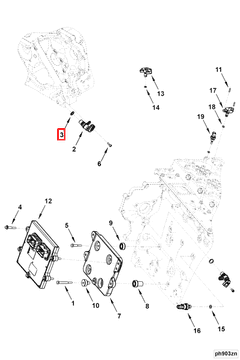

Engine Control Module and Sensor Housings

In the engine control module (ECM) and various sensor housings, the O Ring Seal is used to protect electronic components from moisture and contaminants. This protection is essential for the reliable operation of the ECM and sensors, ensuring accurate data collection and control signals for the engine management system.

Overhaul and Gasket Kits

The O Ring Seal is a common component in overhaul kits and both lower and upper engine gasket sets. Its role in these kits is to replace worn or damaged seals, restoring the engine’s seal integrity. This is particularly important in maintaining compression within the cylinders and preventing oil or coolant leaks, which are critical for engine longevity and performance.

Gear Assembly Housing and Plug

In the gear assembly housing and gear housing plug, the O Ring Seal ensures that the housing remains sealed against external contaminants and internal pressures. This seal is important for the proper functioning of the gear assembly, preventing lubricant loss and contamination, which could lead to increased friction and potential failure of the gear components.

PMM Piston Upgrade and Position Sensor

For the PMM piston upgrade and position sensor applications, the O Ring Seal is used to ensure that the components are properly sealed within their housings. This seal is important for maintaining the accuracy and reliability of the position sensor readings, which are crucial for the precise control of engine operations.

Conclusion

The 4010643 O Ring Seal is a versatile and essential component in various engine systems, contributing to the seal integrity, efficiency, and reliability of the engine. Its application across different engine components underscores its importance in maintaining optimal engine performance.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.