This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 4089120 O Ring Seal is a component designed for use in commercial trucks, manufactured by Cummins Inc. This seal plays a role in maintaining the integrity of various systems within trucks by preventing leaks and ensuring efficient operation 1.

Basic Concepts of O Ring Seals

O Ring Seals are circular rings, typically made from elastomers, that create a seal when compressed within a groove. They function by filling the space between mating surfaces, thereby preventing the passage of fluids or gases. O Ring Seals are widely used in mechanical systems for their simplicity, effectiveness, and versatility in sealing applications 2.

Purpose of the 4089120 O Ring Seal in Truck Operations

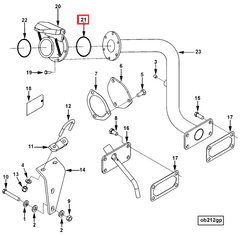

The Cummins 4089120 O Ring Seal is positioned within specific systems of a truck to ensure the sealing of connections, particularly in fluid transfer systems. Its role involves maintaining the pressure integrity of these systems, which is vital for the efficient operation of the truck. The seal is designed to fit into grooves on mating parts, creating a barrier that prevents leaks.

Key Features

The Cummins 4089120 O Ring Seal is characterized by its material composition, typically a durable elastomer that can withstand a range of temperatures and pressures. Its design specifications include precise dimensions to ensure a proper fit and effective sealing. Unique attributes may include resistance to specific chemicals or enhanced flexibility for better performance under varying conditions.

Benefits of Using the 4089120 O Ring Seal

Incorporating the Cummins 4089120 O Ring Seal into truck maintenance and operation offers several advantages. These include increased durability under operational stresses, improved efficiency in sealing applications, and enhanced reliability in preventing leaks. The seal’s design contributes to the overall performance and longevity of the truck’s systems.

Installation and Replacement Guidelines

For the proper installation and replacement of the Cummins 4089120 O Ring Seal, it is important to follow specific guidelines. This includes ensuring the groove is clean and free of debris before insertion, using the correct tools to avoid damage, and checking for proper seating after installation. Common pitfalls to avoid include over-lubrication, which can cause the seal to extrude, and improper sizing, which can lead to leaks.

Troubleshooting Common Issues

Common problems associated with O Ring Seals, such as leaks or failures, can often be traced back to installation errors, material degradation, or operational stresses beyond the seal’s design limits. Troubleshooting methods may involve inspecting the seal for signs of wear or damage, checking the groove for proper fit, and ensuring that operational conditions are within the seal’s specified limits.

Maintenance Tips

Regular maintenance of the Cummins 4089120 O Ring Seal is key to ensuring its longevity and optimal performance. This includes periodic inspections for signs of wear or damage, cleaning the seal and its groove as part of routine maintenance, and replacing the seal according to the manufacturer’s recommendations or when signs of degradation are observed.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a history of innovation and commitment to quality, Cummins serves commercial, industrial, and automotive markets, providing reliable and efficient power solutions for a variety of applications.

Role of Part 4089120 O Ring Seal in Engine Systems

The part 4089120 O Ring Seal is instrumental in ensuring the integrity and efficiency of various engine components. Its application is diverse, spanning multiple critical areas within the engine system.

Oil Fill and Cover Assembly

In the oil fill and cover arrangement, the O Ring Seal is positioned to create a tight seal between the oil filler cap and the engine cover. This seal is essential for preventing oil leaks, which could lead to a loss of lubrication and subsequent engine damage. The seal ensures that the oil remains contained within the system, maintaining the proper lubrication levels necessary for the engine’s moving parts.

Cylinder Block and Cover Interface

At the interface between the cylinder block and the engine cover, the O Ring Seal plays a significant role. It ensures that there are no gaps through which oil or other fluids could escape. This is particularly important in high-pressure environments where even a small leak could lead to significant issues. The seal helps in maintaining the pressure integrity of the system, ensuring that the engine operates smoothly and efficiently.

Hand Hole Covers

Hand hole covers, which provide access to internal engine components for maintenance and repair, also benefit from the O Ring Seal. The seal prevents contaminants from entering the engine through these access points, which is vital for maintaining the cleanliness and performance of the engine’s internal components. It also ensures that any fluids within the engine do not leak out through these covers.

Filler Cap Seal

The filler cap, used for adding oil to the engine, relies on the O Ring Seal to create a secure closure. This seal is important for preventing oil from spilling out when the cap is in place, as well as for keeping contaminants out of the engine when the cap is removed. The integrity of this seal directly impacts the engine’s lubrication system, ensuring that the oil level remains consistent and that the engine is protected from external debris.

Conclusion

In summary, the Cummins 4089120 O Ring Seal is a versatile and essential component that fits seamlessly with a range of Cummins engines, ensuring their systems operate efficiently and reliably. Its role in maintaining the integrity of various engine systems cannot be overstated, making it a critical component in the maintenance and operation of commercial trucks.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.