This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 4902825 O Ring Seal is a component utilized in the maintenance and operation of commercial trucks. It is engineered to provide a reliable seal in various applications within the truck’s systems, ensuring the integrity of fluid systems and preventing leaks. This part plays a role in maintaining the efficiency and reliability of commercial truck operations.

Basic Concepts of O Ring Seals

O Ring Seals are circular elastomeric rings used to create a seal between two or more mating surfaces. They function by deforming slightly when compressed, filling the gap between the surfaces and preventing the passage of fluids or gases. O Ring Seals are widely used in mechanical systems due to their simplicity, effectiveness, and versatility in various applications, including hydraulic, pneumatic, and fuel systems 1.

Purpose of the 4902825 O Ring Seal in Truck Operation

This Cummins part plays a specific role in the operation of commercial trucks by ensuring the integrity of seals in critical fluid systems. It is typically placed in areas where fluid transfer occurs, such as fuel injectors, hydraulic systems, or coolant passages. Its function is to maintain a tight seal, preventing leaks and ensuring that fluids are directed correctly within the system.

Key Features of the 4902825 O Ring Seal

The Cummins 4902825 O Ring Seal is characterized by several unique features that make it suitable for its intended applications. These include its material composition, which is typically a durable elastomer resistant to various chemicals and temperatures. The size of the O Ring Seal is designed to fit specific applications, ensuring a proper seal. Additionally, special manufacturing processes may be employed to enhance its durability and performance under operating conditions.

Benefits of Using the 4902825 O Ring Seal

The use of this Cummins part offers several advantages. These include improved sealing efficiency, which helps maintain system integrity and prevent leaks. The seal’s durability ensures long-term performance, even under challenging operating conditions. Additionally, its resistance to various fluids and temperatures makes it a reliable choice for commercial truck applications.

Installation and Replacement Guidelines

Proper installation and replacement of the Cummins 4902825 O Ring Seal involve several steps. First, ensure the mating surfaces are clean and free of debris. Use appropriate tools to remove the old seal, taking care not to damage the surfaces. When installing the new seal, lubricate it slightly to facilitate placement and ensure it is seated correctly in the groove. Follow any specific guidelines provided by the manufacturer to ensure a proper fit and function 2.

Troubleshooting Common Issues with O Ring Seals

Common issues with O Ring Seals include leaks or failures, which can be caused by wear, improper installation, or exposure to incompatible fluids. To diagnose these issues, inspect the seal for signs of damage or deformation. If a leak is detected, carefully remove the seal and examine the mating surfaces for debris or damage. Replacing the seal with a new one, ensuring proper installation, can often resolve these issues.

Maintenance Tips for O Ring Seals

Regular maintenance of O Ring Seals is important to ensure longevity and optimal performance. This includes periodic inspection for signs of wear or damage, cleaning the seals and mating surfaces to remove debris, and replacing seals as needed. Following manufacturer guidelines for maintenance can help prevent issues and ensure the seals continue to function effectively.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins serves commercial truck, bus, construction, agricultural, and power generation markets. The company is known for its commitment to providing reliable and efficient power solutions, backed by a strong reputation in the industry.

Cummins O Ring Seal 4902825 Compatibility

The Cummins O Ring Seal part number 4902825 is designed to fit a variety of engine models, ensuring a reliable seal in critical areas. This O ring is crucial for maintaining the integrity of fluid systems and preventing leaks. Below is a detailed overview of the engines this part is compatible with:

K Series Engines

- K19: This engine benefits from the O ring seal in maintaining fluid system integrity.

- K38: The seal ensures that the engine’s fluid systems remain leak-free.

- K50: The O ring is essential for the proper functioning of the engine’s fluid pathways.

L Series Engines

- L10 MECHANICAL: The O ring seal is crucial for the mechanical operations of this engine.

M Series Engines

- M11 CELECT PLUS: The seal helps in maintaining the efficiency of the engine’s fluid systems.

- M11 MECHANICAL: This engine relies on the O ring to prevent leaks and ensure smooth operation.

N Series Engines

- N14 MECHANICAL: The seal is vital for the mechanical integrity of this engine.

NH/NT Series Engines

- NH/NT 855: The O ring ensures that the engine’s fluid systems are properly sealed.

V Series Engines

- V28: The seal is essential for maintaining the fluid system’s integrity in this engine.

- V903: The O ring ensures that the engine’s fluid pathways are leak-free.

Each of these engines, regardless of their specific design and operational characteristics, relies on the Cummins O Ring Seal 4902825 to maintain the efficiency and reliability of their fluid systems.

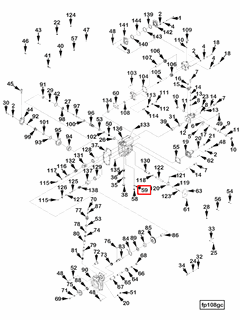

Role of Part 4902825 O Ring Seal in Engine Systems

The O Ring Seal, identified as part 4902825, is integral to the efficient operation of various engine systems. Its primary function is to ensure a secure and leak-proof seal in components where fluid dynamics and pressure integrity are paramount.

Integration with Fuel Systems

In the AFC-VS/Road Speed system, the O Ring Seal is employed to maintain the integrity of connections between the variable speed hydraulic assembly and the fuel lines. This ensures that the fuel delivery remains consistent, regardless of the engine’s operational speed.

For the Aftercooler Variable Speed Hydraulic Assembly, the O Ring Seal plays a significant role in sealing the hydraulic lines that modulate the aftercooler’s performance. This is essential for maintaining optimal fuel temperature and pressure, which directly impacts engine efficiency.

Application in Pumps

The Fuel (Variable Speed) Pump relies on the O Ring Seal to prevent fuel leakage at critical connection points. This is particularly important in variable speed applications where the pump’s operational range is extensive.

In the Fuel Aftercooler Pump and Fuel Gear Pump, the O Ring Seal ensures that the pressurized fuel pathways remain sealed, which is vital for the consistent performance of these pumps under varying load conditions.

Fuel Injection Systems

For the Fuel Injection Pump and associated components like the Fuel Pump & Drive (EFC) and Fuel Pump & Drive (Wood), the O Ring Seal is used to secure connections that deliver fuel to the injection system. This is essential for precise fuel metering and injection timing.

Specialized Fuel Systems

In systems like the Fuel Pump & Gov Sump and Fuel Pump AFC-VS, the O Ring Seal is critical for sealing the sump and governor connections, ensuring that the fuel supply remains uncontaminated and pressurized.

Throttle Control and Miscellaneous Components

The Throttle Control system also benefits from the O Ring Seal, particularly in setups like the Fuel Pump, VS & TC. Here, the seal ensures that the throttle control mechanism operates smoothly without fuel leaks, which could otherwise disrupt engine performance.

Conclusion

In summary, the O Ring Seal (part 4902825) is a fundamental component across various engine systems, ensuring that fuel pathways remain sealed and operational integrity is maintained. Its role in preventing leaks and maintaining system efficiency underscores its importance in the operation of commercial trucks.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.