4974852

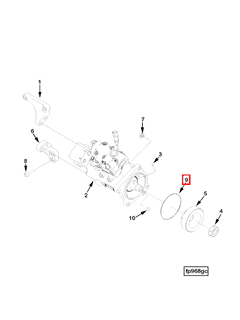

O Ring Seal

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 4974852 O Ring Seal is a critical component designed to maintain the integrity of seals within commercial truck systems. Its primary function is to prevent leaks and ensure system efficiency, contributing to the reliable performance of various mechanical systems in commercial trucks.

Basic Concepts of O Ring Seals

An O Ring Seal is a type of gasket made from a toroidal (ring-shaped) piece of elastomeric material. When compressed between two surfaces, it creates a seal. Common materials include nitrile rubber, silicone, and fluorocarbon, chosen for their flexibility, resistance to compression set, and compatibility with various fluids and operating conditions 1. The primary function of an O Ring Seal is to prevent the escape of fluids or gases from a system.

Role of the 4974852 O Ring Seal in Truck Operation

This Cummins part plays a specific role in truck operation by maintaining seals within the engine or other systems. It is typically found in areas requiring fluid or gas containment to prevent leaks, which can lead to system inefficiencies or failures 2.

Key Features of the 4974852 O Ring Seal

The 4974852 O Ring Seal is characterized by its durable elastomer design, providing resistance to a range of operating conditions. Its design ensures a snug fit within the designated groove, crucial for sealing capabilities. Unique characteristics may include specific durometer ratings or temperature resistance, enhancing performance in demanding environments 3.

Benefits of Using the 4974852 O Ring Seal

Using this part offers several benefits, including improved sealing efficiency, which helps maintain system pressure and prevent leaks. Its durability ensures long-term performance, reducing the need for frequent replacements. Additionally, its resistance to various operating conditions, including temperature extremes and exposure to chemicals, makes it a reliable choice for commercial truck applications 4.

Installation and Maintenance

Proper installation of the 4974852 O Ring Seal involves cleaning the groove, lubricating the seal before installation, and following best practices to facilitate seating and prevent damage. Maintenance tips include regular inspection for wear or damage and replacement according to manufacturer guidelines or routine maintenance schedules 5.

Troubleshooting Common Issues

Common problems with O Ring Seals, such as leaks or failures, can often be traced to installation errors, material degradation, or incompatible operating conditions. Troubleshooting steps may involve inspecting the seal and its groove for damage, ensuring proper installation techniques were used, and verifying compatibility with the system’s operating conditions. Addressing these issues promptly can help maintain system efficiency and prevent more significant problems 6.

Manufacturer: Cummins

Cummins is a reputable manufacturer known for its commitment to quality and innovation in commercial truck components. The company offers a wide range of products designed to enhance the performance and reliability of commercial trucks. Their reputation is built on a history of delivering durable and efficient solutions to meet the demands of the transportation sector 7.

Cummins O Ring Seal 4974852 Compatibility

The Cummins O Ring Seal part number 4974852 is designed to fit a variety of Cummins engines, ensuring a reliable seal in critical areas. This seal is essential for maintaining the integrity of engine systems by preventing leaks and ensuring that components function correctly.

ISX12 Series

- ISX12 CM2350 X102

- ISX12 G CM2180 EJ

- ISX12/ISX11.9 CM2250

The ISX12 series engines benefit from the 4974852 O Ring Seal in various applications, including fuel systems, hydraulic systems, and other areas where a robust seal is necessary to prevent fluid leakage.

ISZ13 Series

- ISZ13 CM2150 Z105

The ISZ13 engine utilizes the 4974852 O Ring Seal in critical sealing applications, ensuring that the engine operates efficiently and reliably.

QSX11.9 Series

- QSX11.9 CM2250 ECF

In the QSX11.9 engine, the 4974852 O Ring Seal is used to maintain the integrity of the engine’s systems, providing a dependable seal that is crucial for performance and longevity.

QSZ13 Series

- QSZ13 CM2150 Z101

- QSZ13 CM2150 Z102

The QSZ13 engines incorporate the 4974852 O Ring Seal in several sealing applications, ensuring that the engine’s components remain sealed and protected from leaks.

Z13 Series

- Z13 Z108G

The Z13 engine also relies on the 4974852 O Ring Seal for critical sealing tasks, ensuring that the engine operates smoothly and efficiently.

Role of Part 4974852 O Ring Seal in Engine Systems

The 4974852 O Ring Seal is an essential component in ensuring the integrity and efficiency of various engine systems. Its application spans across multiple critical areas, contributing to the overall performance and reliability of the engine.

Breather and Crankcase Systems

In the breather and crankcase systems, the O Ring Seal plays a significant role in maintaining a sealed environment. It prevents the escape of crankcase gases and ensures that the breather system functions correctly by allowing controlled ventilation. This seal is particularly important in preventing contamination and maintaining the proper pressure within the crankcase.

Compressor and Air Intake

Within the compressor and air intake systems, the O Ring Seal is used to ensure a tight connection between components. This is vital for maintaining the efficiency of the air compression process and ensuring that the air intake system delivers clean, unfiltered air to the engine. A well-sealed system enhances the compressor’s performance and contributes to better engine breathing.

Housing and Rear Gear

In the housing and rear gear assemblies, the O Ring Seal is employed to prevent leaks and ensure that lubricants remain contained within the system. This is essential for the smooth operation of the rear gear and the longevity of the housing components. Proper sealing helps in reducing wear and tear and maintaining the efficiency of these parts.

Lower and Upper Engine Gasket Kits

The O Ring Seal is a common component in both lower and upper engine gasket kits. It ensures that the gaskets form a reliable seal between engine components, preventing coolant, oil, or other fluids from leaking. This is important for maintaining the engine’s thermal management and lubrication systems.

Overhaul Kit

In an overhaul kit, the O Ring Seal is used to replace worn-out seals during engine maintenance. This ensures that the engine components are reassembled with fresh, reliable seals, contributing to the engine’s restored performance and longevity.

Pump and Fuel Systems

For pump and fuel systems, the O Ring Seal is critical in maintaining the integrity of fuel lines and connections. It ensures that fuel is delivered without leaks, which is essential for the engine’s consistent performance and safety.

Regulator and Fuel Pressure

In the regulator and fuel pressure systems, the O Ring Seal helps in maintaining consistent fuel pressure by ensuring that there are no leaks in the fuel lines or connections. This consistency is vital for the engine’s combustion efficiency and overall performance.

Turbocharger Gasket and Kit

In turbocharger gasket kits and turbocharger kits, the O Ring Seal is used to ensure that the turbocharger components are tightly sealed. This is important for maintaining the turbocharger’s efficiency and preventing leaks that could affect the engine’s boost pressure and performance.

Conclusion

The Cummins 4974852 O Ring Seal is a vital component in the operation and maintenance of commercial truck engines. Its role in preventing leaks and maintaining system efficiency across various engine systems underscores its importance in ensuring the reliable performance of commercial trucks. Proper installation, maintenance, and timely replacement of this part are essential for the longevity and efficiency of engine systems.

-

Shashank Arora, Alireza Tashakori Abkenar, and Shantha Gamini Jayasi, Heavyduty Electric Vehicles: From Concept to Reality, Elsevier, 2021.

↩ -

Michael Hilgers, Transmissions and Drivetrain Design, Springer Vieweg, 2022.

↩ -

Pawel Drozdziel, The Vehicle Diesel Engine Startup Process Operational and Environmental Aspects, Routledge, 2023.

↩ -

Tim Giles, Automotive Engines Diagnosis Repair and Rebuilding, Cengage Learning, 2019.

↩ -

Cummins, Service Manual (4326168), QSB6.7 CM2150 B109.

↩ -

Cummins, Service Manual (4326168), QSB6.7 CM2150 B109.

↩ -

Cummins, Service Manual (4326168), QSB6.7 CM2150 B109.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.