4989613

O Ring Seal

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 4989613 O Ring Seal is a vital component in the maintenance and operation of commercial trucks. This seal ensures the efficient and reliable performance of various truck systems. Cummins, a leading name in the commercial truck industry, manufactures this O Ring Seal as part of its extensive range of high-quality parts designed to meet the demanding requirements of truck operations.

Basic Concepts of O Ring Seals

O Ring Seals are circular rings, typically made from elastomers, that create seals in mechanical systems. They function by being seated in a groove and compressed during assembly between two or more mating surfaces. This compression allows the O Ring to seal the gap between the surfaces, preventing the leakage of fluids or gases. O Rings are widely used in various applications due to their simplicity, effectiveness, and versatility in creating reliable seals 1.

Purpose of the 4989613 O Ring Seal in Truck Operation

The 4989613 O Ring Seal plays a specific role in the operation of commercial trucks by ensuring the integrity of seals in various systems and components. It is commonly associated with fuel systems, where it helps maintain the seal between components, preventing fuel leaks. Additionally, it may be used in other systems where fluid or gas sealing is required to ensure the efficient operation of the truck 2.

Key Features of the 4989613 O Ring Seal

The 4989613 O Ring Seal is designed with specific characteristics that enhance its effectiveness and durability in truck applications. It is made from high-quality elastomer materials that offer excellent resistance to a range of environmental factors, including temperature variations, chemical exposure, and mechanical stress. The design of the seal ensures a tight fit in its designated groove, providing a reliable barrier against leaks 3.

Benefits of Using the 4989613 O Ring Seal

Utilizing the 4989613 O Ring Seal in truck applications offers several advantages. Its design and material properties contribute to improved sealing performance, ensuring that fluids or gases are contained within the system. The seal’s durability and resistance to environmental factors enhance its longevity, reducing the need for frequent replacements. Additionally, its reliable performance helps maintain the efficiency and safety of truck operations.

Installation Considerations

Proper installation of the 4989613 O Ring Seal is vital to ensure its optimal performance and longevity. Guidelines for installation include ensuring the groove is clean and free from debris before placing the seal. The seal should be lubricated to facilitate easy installation and to prevent damage. Care should be taken to avoid twisting or pinching the seal during installation, as this can compromise its sealing ability.

Troubleshooting Common Issues

Common problems associated with O Ring Seals in truck applications include leaks, which may indicate a faulty seal. Troubleshooting steps include inspecting the seal for signs of wear, damage, or improper installation. If the seal appears compromised, it should be replaced. Regular inspections and maintenance can help identify and address issues before they lead to significant problems.

Maintenance Tips

Regular maintenance and inspection of the 4989613 O Ring Seal are recommended to prevent failures and ensure continued reliable operation. This includes checking for signs of wear or damage during routine maintenance checks and replacing the seal as necessary. Keeping the area around the seal clean and free from contaminants can also help maintain its performance.

Cummins: A Brief Overview

Cummins is a renowned manufacturer in the commercial truck industry, known for its wide range of high-quality parts and engines. With a history of innovation and excellence, Cummins has established a strong reputation for producing reliable and durable components that meet the rigorous demands of truck operations. Their product range includes engines, filtration systems, and aftermarket parts, all designed to enhance the performance and efficiency of commercial trucks.

O Ring Seal Part 4989613 Compatibility with Cummins Engines

The O Ring Seal part 4989613, manufactured by Cummins, is designed to fit a variety of Cummins engines, ensuring a secure seal and preventing leaks. This seal is integral to maintaining the integrity of engine systems and is compatible with the following engines:

ISC Series Engines

- ISC CM554

- ISC CM850 (CM2850)

- ISL CM554

- ISL9 CM2150 SN

- ISL9 CM2250

- ISL9.5 CM2880 L138

- QSL9 CM554

- QSL9 CM850 (CM2850)

ISG Series Engines

- ISG11 CM2880 G108

- ISG12 CM2880 G107

- ISG12 G CMOH6.0 G111

QSG Series Engines

- QSG12 CM2880 G112

- QSG12/X12 CM2350 G110

X12 Series Engines

- X12 CM2350 X119B

- X12 CM2670 X121B

QSC Series Engines

- QSC8.3 CM554

- QSC8.3 CM850 (CM2850)

L Series Engines

- L GAS PLUS CM556

- L8.9

- L8.9G CMOH2.0 L125B

Other Series Engines

- 6C8.3

- C GAS PLUS CM556

- QSL8.9 CM2150 L141

- X11 CM2670 X126B

This O Ring Seal is meticulously engineered to fit snugly within the specified engine models, ensuring optimal performance and reliability. Its compatibility across a wide range of Cummins engines underscores its versatility and importance in maintaining engine efficiency and longevity.

Role of Part 4989613 O Ring Seal in Engine Systems

The Part 4989613 O Ring Seal is integral to maintaining the integrity and efficiency of various engine systems. Its application spans across multiple components, ensuring optimal performance and preventing leaks.

Integration with Key Components

Corrosion Resistor and Corrosion Resistor Head

The O Ring Seal is employed in the assembly of the corrosion resistor and its head. It ensures a tight seal, preventing any fluid leakage that could compromise the resistor’s effectiveness in protecting engine components from corrosion.

Corrosion Resistor Location

At the corrosion resistor location, the O Ring Seal plays a vital role in securing the connection points. This prevents the ingress of contaminants and ensures the longevity of the corrosion protection system.

Leak Test Adapter

In the context of the leak test adapter, the O Ring Seal is used to create a sealed environment necessary for accurate leak detection. Its precision fitting is essential for reliable test results.

Lower and Upper Engine Gasket Kits

Both the lower and upper engine gasket kits utilize the O Ring Seal to ensure a robust seal between mating surfaces. This is particularly important in high-pressure areas to prevent oil and coolant leaks.

Lubricating Oil Transfer Tube

The O Ring Seal is critical in the lubricating oil transfer tube system, where it maintains the seal at connection points. This ensures consistent oil flow and pressure, vital for engine lubrication.

Mounting Kit

In the mounting kit, the O Ring Seal is used to secure various engine components in place. Its role is to prevent fluid leaks around the mounting points, ensuring a stable and leak-free installation.

Oil Cooler Leak Test Kit

For the oil cooler leak test kit, the O Ring Seal is essential in creating a sealed testing environment. This allows for accurate assessment of the oil cooler’s integrity without external contamination.

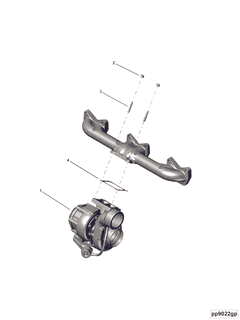

Turbocharger Components

In the turbocharger gasket kit, turbocharger kit, turbocharger oil supply tube, and turbocharger plumbing, the O Ring Seal is used extensively. It ensures that the high-pressure oil supply to the turbocharger is maintained without leaks, which is crucial for turbocharger efficiency and engine performance.

The Part 4989613 O Ring Seal, through its application in these diverse engine components, contributes significantly to the overall reliability and performance of the engine system.

Conclusion

The Cummins 4989613 O Ring Seal is a critical component in the maintenance and operation of commercial trucks. Its design, material properties, and compatibility with a wide range of Cummins engines make it an essential part for ensuring the integrity and efficiency of various engine systems. Proper installation, regular maintenance, and timely replacement of this part are vital for the continued reliable operation of truck systems.

-

Diesel Technology Fundamentals Service Repair Eighth Edition, Andrew Norman, The Goodheart-Willcox Company Inc, 2016

↩ -

Diesel Engine Combustion, Emissions and Condition Monitoring, Saiful Bari, InTech, 2013

↩ -

Internal Combustion Engine Bearings Lubrication in Hydrodynamic Bearings, Dominique Bonneau, Aurelian Fatu and Dominique Souchet, Wiley-ISTE, 2014

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.