4989614

O Ring Seal

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

Minimum Quantity 6

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 4989614 O Ring Seal is a component designed to ensure the integrity of seals in commercial truck operations. An O Ring Seal is a type of gasket consisting of a jointless ring of elastomeric material used for creating seals between two or more parts. In the automotive industry, O Ring Seals are commonly employed to prevent leaks of fluids and gases, ensuring the efficient operation of various systems 1.

Basic Concepts of O Ring Seals

O Ring Seals are designed with a circular cross-section, which allows them to create a seal when compressed within a groove. They are typically made from materials such as nitrile rubber, silicone, or fluorocarbon, chosen for their resistance to various chemicals and temperatures. The primary function of an O Ring Seal is to provide a barrier that prevents the escape of fluids or gases from a system. Proper sealing is vital in mechanical systems to maintain performance, prevent contamination, and ensure safety 2.

Purpose of the Cummins 4989614 O Ring Seal

The Cummins 4989614 O Ring Seal plays a specific role in the operation of commercial trucks by ensuring the integrity of seals in various systems. It contributes to the efficiency and reliability of truck components by preventing leaks and maintaining system pressure. This O Ring Seal is typically used in connections where fluid or gas sealing is required, such as in fuel systems, hydraulic systems, and engine components 3.

Key Features

The Cummins 4989614 O Ring Seal is characterized by its robust design and material properties, making it suitable for heavy-duty applications. It is crafted from high-quality elastomeric materials that offer excellent resistance to wear, chemicals, and temperature extremes. The seal’s durability and performance attributes ensure it can withstand the demanding conditions encountered in commercial truck operations 4.

Benefits

Utilizing the Cummins 4989614 O Ring Seal in commercial truck maintenance and operation offers several advantages. It enhances the performance and reliability of truck components by ensuring effective sealing, which can lead to improved efficiency and longevity of the systems. Additionally, the use of high-quality O Ring Seals can result in potential cost savings by reducing the need for frequent replacements and repairs 5.

Installation and Maintenance

Proper installation of the Cummins 4989614 O Ring Seal is crucial for ensuring its effectiveness. It should be seated correctly within the groove to achieve a proper seal. Regular maintenance, including inspection for wear or damage, is recommended to ensure longevity and optimal performance. Common issues that may arise include seal deformation or failure, which can often be addressed by replacement or adjustment 6.

Troubleshooting

Common problems associated with O Ring Seals include leaks, which can be diagnosed through visual inspection or pressure testing. A step-by-step troubleshooting guide for issues related to the Cummins 4989614 O Ring Seal involves identifying the source of the leak, assessing the condition of the seal, and determining whether replacement or repair is necessary. Preventive measures to avoid seal failure include regular maintenance and using the correct installation procedures 7.

Compatibility and Applications

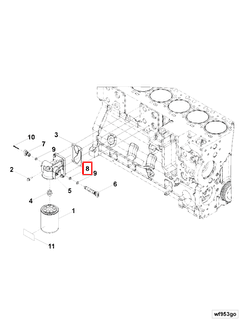

The Cummins 4989614 O Ring Seal is designed for use in specific applications within commercial trucks. It is commonly employed in systems and components where fluid or gas sealing is critical. Ensuring compatibility with other parts and systems is important for maintaining the integrity of the seal and the overall performance of the truck 8.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a history of innovation and a commitment to quality, Cummins plays a significant role in the commercial truck industry by providing reliable and efficient components that contribute to the performance and longevity of commercial vehicles.

Cummins O Ring Seal 4989614 Compatibility

The Cummins O Ring Seal part number 4989614 is a versatile component designed to fit a variety of Cummins engines. This seal is essential for maintaining the integrity of fluid systems by preventing leaks and ensuring that the engine operates efficiently.

ISC Series Engines

The ISC CM554 and ISC CM850 engines are part of the ISC series, which are known for their reliability and efficiency. The O Ring Seal 4989614 is compatible with these engines, providing a critical seal in various fluid systems.

ISL Series Engines

The ISL CM554, ISL9 CM2150 SN, ISL9 CM2250, and ISL9.5 CM2880 L138 engines are part of the ISL series, designed for heavy-duty applications. The O Ring Seal 4989614 fits these engines, ensuring that fluid systems remain sealed and operational.

ISX Series Engines

The ISX15 CM2250, ISX15 CM2250 SN, and ISX15 CM2350 X101 engines are part of the ISX series, known for their high performance and durability. The O Ring Seal 4989614 is compatible with these engines, providing a reliable seal in various fluid systems.

L Series Engines

The L GAS PLUS CM556 and L8.9 engines are part of the L series, designed for lighter applications. The O Ring Seal 4989614 fits these engines, ensuring that fluid systems remain sealed and operational.

QSC and QSL Series Engines

The QSC8.3 CM554, QSC8.3 CM850(CM2850), QSL8.9 CM2150 L141, and QSL9 CM850(CM2850) engines are part of the QSC and QSL series, designed for a range of applications. The O Ring Seal 4989614 is compatible with these engines, providing a critical seal in various fluid systems.

QSX Series Engines

The QSX15 CM2250 ECF and QSX15 CM2350 X105 engines are part of the QSX series, known for their efficiency and reliability. The O Ring Seal 4989614 fits these engines, ensuring that fluid systems remain sealed and operational.

This O Ring Seal is a crucial component for maintaining the performance and longevity of these engines, ensuring that fluid systems remain sealed and operational.

Role of Part 4989614 O Ring Seal in Engine Systems

The 4989614 O Ring Seal is an essential component in maintaining the integrity and efficiency of various engine systems. Its primary function is to create a secure seal between different components, preventing leaks and ensuring optimal performance.

Compressor Systems

In compressor systems, the 4989614 O Ring Seal is utilized to seal connections between the compressor and the air intake system. This seal is vital for maintaining the pressure differential required for efficient compression. Without a proper seal, compressed air could escape, leading to reduced efficiency and potential damage to the compressor.

Air Systems

Within air systems, the O Ring Seal is employed at various junctures to ensure that the airflow remains uninterrupted and uncontaminated. This is particularly important in systems where air quality is paramount, such as in respiratory equipment or precision instrumentation.

Corrosion Resistor Head and Flexible Hose

When integrating a corrosion resistor head with a flexible hose, the 4989614 O Ring Seal plays a significant role. It ensures that the connection between these components remains leak-free, even under varying pressure conditions. This is essential for maintaining the longevity of the corrosion resistor head and preventing environmental contamination.

Location-Specific Applications

In specific locations within an engine, such as around corrosion resistors or within lower engine gasket kits, the O Ring Seal is used to prevent fluid leaks. This is particularly important in areas where even a small leak could lead to significant engine damage or reduced performance.

Overhaul Kits

During engine overhauls, the 4989614 O Ring Seal is often included in overhaul kits to replace worn or damaged seals. This ensures that all connections are secure and leak-free post-overhaul, contributing to the engine’s overall reliability and performance.

General Use in Engine Systems

Across various engine systems, the 4989614 O Ring Seal is a fundamental component for ensuring that connections between different parts remain intact. Whether it’s sealing a corrosion resistor or ensuring the integrity of a lower engine gasket kit, the O Ring Seal is indispensable for maintaining engine efficiency and longevity.

Conclusion

The Cummins 4989614 O Ring Seal is a critical component in the maintenance and operation of commercial trucks and various engine systems. Its robust design, material properties, and compatibility with a wide range of Cummins engines make it an indispensable part for ensuring the integrity of seals, preventing leaks, and maintaining system efficiency. Proper installation, regular maintenance, and troubleshooting are essential for maximizing the performance and longevity of this Cummins part.

-

Khajepour, A. (2023). Synthesis Lectures on Advances in Automotive Technology. Springer.

↩ -

Boyce, M. P. (2011). Gas Turbine Engineering Handbook (4th ed.). Butterworth-Heinemann.

↩ -

Hu, H., Smaling, R., & Baseley, S. (2014). Heavy-Duty Wheeled Vehicles. SAE International.

↩ -

Schuetz, T. (2016). Aerodynamics of Road Vehicles: Fifth Edition. SAE International.

↩ -

Khajepour, A. (2023). Synthesis Lectures on Advances in Automotive Technology. Springer.

↩ -

Boyce, M. P. (2011). Gas Turbine Engineering Handbook (4th ed.). Butterworth-Heinemann.

↩ -

Hu, H., Smaling, R., & Baseley, S. (2014). Heavy-Duty Wheeled Vehicles. SAE International.

↩ -

Schuetz, T. (2016). Aerodynamics of Road Vehicles: Fifth Edition. SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.