4992509

O Ring Seal

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction To O Ring Seals

O ring seals are indispensable components in various mechanical systems, particularly in commercial trucks and heavy-duty engines. These seals are crafted to create a tight seal between two surfaces, effectively preventing the leakage of fluids or gases. The unique design of the O ring allows it to compress and expand, ensuring a reliable seal under varying pressures and temperatures. This adaptability makes O rings a critical element in maintaining the integrity and efficiency of mechanical systems 1.

The Role Of The Cummins 4992509 O Ring Seal In Truck Engines

The Cummins 4992509 O Ring Seal is specifically engineered for use in commercial truck engines. Its primary function is to ensure a secure seal in critical areas where fluid or gas leakage could lead to engine damage or reduced performance. This O Ring Seal is typically employed in high-pressure systems, such as fuel injection systems, hydraulic systems, and coolant passages. By providing a reliable seal, it helps maintain the efficiency and performance of the engine, ensuring that the truck operates smoothly and efficiently 2.

How The Cummins 4992509 O Ring Seal Works

The Cummins 4992509 O Ring Seal operates by compressing between two surfaces when pressure is applied. This compression creates a tight seal, preventing the passage of fluids or gases. The O Ring’s material, often made from high-quality synthetic rubber or elastomer, ensures durability and resistance to various environmental factors, such as heat, chemicals, and abrasion. This robust material selection is crucial for withstanding the demanding conditions within a commercial truck engine 3.

Importance Of The Cummins 4992509 O Ring Seal In Truck Operations

The Cummins 4992509 O Ring Seal plays a crucial role in the efficient operation of commercial trucks. By maintaining a secure seal, it helps prevent leaks that could lead to engine damage, reduced performance, and costly repairs. Additionally, the O Ring Seal contributes to the overall reliability and longevity of the engine, ensuring that the truck can operate at peak efficiency. This reliability is particularly important in commercial operations where downtime can lead to significant financial losses.

Troubleshooting And Maintenance Tips

Regular inspection and maintenance of the Cummins 4992509 O Ring Seal are essential to ensure its proper function. Here are some troubleshooting and maintenance tips:

- Visual Inspection: Regularly check the O Ring Seal for signs of wear, cracks, or deformation. If any damage is detected, the O Ring Seal should be replaced immediately to prevent potential leaks and engine damage.

- Cleanliness: Keep the O Ring Seal and its mating surfaces clean to prevent contamination that could affect the seal’s performance. Contaminants can compromise the seal’s ability to create a tight barrier, leading to leaks.

- Proper Installation: Ensure that the O Ring Seal is correctly installed according to the manufacturer’s specifications. Incorrect installation can lead to seal failure and potential engine damage. Following the correct installation procedures is crucial for the seal’s effectiveness.

- Replacement: Follow the recommended replacement intervals for the Cummins 4992509 O Ring Seal as specified by Cummins or the truck manufacturer. Regular replacement helps maintain the seal’s effectiveness and prevents unexpected failures, ensuring the continued reliability of the engine.

Cummins O Ring Seal 4992509 Compatibility

The Cummins O Ring Seal part number 4992509 is designed to fit a variety of Cummins engines. This seal is essential for maintaining the integrity of various engine components by preventing leaks and ensuring a proper seal in critical areas. Below is a detailed breakdown of the engines with which this O Ring Seal is compatible:

ISC Series Engines

- ISC CM2150

- ISC CM850

- ISC8.3 CM2250

- ISL CM2150

- ISL G CM2180

- ISL9 CM2150 SN

- ISL9 CM2250

- ISL9.5 CM2880 L138

ISB Series Engines

- ISB5.9G CM2180

- ISB6.7 CM2250

- ISB6.7 CM2350 B101

- ISB6.7 G CM2180 B118

ISG and QSB Series Engines

- ISG12 CM2880 G107

- QSB4.5 CM2250 EC

- QSB4.5 CM850 (CM2850)

- QSB6.7 CM2250

- QSB6.7 CM2350 B105

CM2670 Series Engines

- B5.6 CM2670 B152B

- B5.9 CM2670 B166C

- B6.7 CM2670 B153B

- B6.7 CM2670 B164C

- L8.9 CM2670 L134C

- L9 CM2670 L128B

- L8.9 L121

This O Ring Seal is engineered to fit seamlessly into the specified engine models, ensuring optimal performance and longevity. It is crucial to verify the compatibility of this seal with your specific engine model to ensure proper fit and function.

Role of Part 4992509 O Ring Seal in Engine Systems

The 4992509 O Ring Seal is integral to maintaining the efficiency and reliability of various engine components. Its application spans across multiple systems, ensuring optimal performance and longevity.

Accessories

In the realm of engine accessories, the O Ring Seal is employed to create secure connections between components. This ensures that fluids and gases are effectively contained, preventing leaks that could compromise the operation of accessories such as pumps and sensors.

Exhaust Outlet

At the exhaust outlet, the O Ring Seal plays a significant role in sealing the connection between the exhaust manifold and the turbocharger. This seal is essential for maintaining the integrity of the exhaust flow, reducing emissions, and enhancing engine performance.

Air Intake Connection

For the air intake connection, the O Ring Seal ensures a tight seal between the air intake system and the engine. This is vital for maintaining the correct air-fuel ratio, which is fundamental for combustion efficiency and overall engine performance.

Air Shutdown Device and Air Shutoff Valve

In systems involving the air shutdown device and air shutoff valve, the O Ring Seal is used to prevent air leaks. This is particularly important during engine shutdown procedures, where maintaining a seal is necessary to ensure the engine can be restarted without issues.

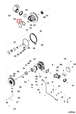

Turbocharger Arrangement and Turbocharger Gasket Kit

Within the turbocharger arrangement, the O Ring Seal is utilized in conjunction with the turbocharger gasket kit to ensure that the turbocharger operates within its designed parameters. This includes sealing the connections between the turbocharger and the engine, as well as within the turbocharger itself, to maintain boost pressure and efficiency.

Upper Engine Gasket Kit and Upper Engine Gasket Set

In the upper engine gasket kit and upper engine gasket set, the O Ring Seal is employed to create reliable seals between various engine components. This is essential for preventing coolant and oil leaks, which could lead to engine damage and reduced performance.

Air Transfer Device and Air Shutdown Arrangement

For the air transfer device and air shutdown arrangement, the O Ring Seal ensures that air is effectively transferred and sealed off as required. This is crucial for maintaining the engine’s air management system, which directly impacts combustion efficiency and emissions control.

In summary, the 4992509 O Ring Seal is a versatile component that enhances the functionality and reliability of various engine systems by ensuring secure and leak-proof connections.

Conclusion

Understanding the importance and function of the Cummins 4992509 O Ring Seal is crucial for engineers, mechanics, truck drivers, and fleet operators. By maintaining and properly troubleshooting this essential component, professionals can ensure the reliable operation of commercial truck engines, ultimately contributing to the overall efficiency and performance of their fleets. Regular maintenance and adherence to manufacturer guidelines will help maximize the lifespan and effectiveness of the O Ring Seal, ensuring that commercial trucks remain operational and efficient.

-

Hilgers, Michael. Transmissions and Drivetrain Design. Springer Vieweg, 2022.

↩ -

Ferrari, Alessandro, and Pietro Pizzo. Injection Technologies: Mixture Formation Strategies. SAE International, 2022.

↩ -

Reif, Konrad, ed. Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg, 2014.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.