4995093

O Ring Seal

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 4995093 O Ring Seal is a critical component designed to maintain the integrity of seals in various systems within commercial trucks. Its primary function is to prevent leaks and ensure system efficiency, which is vital for the overall maintenance and performance of commercial vehicles.

Basic Concepts of O Ring Seals

O Ring Seals are circular rings, typically made from elastomers, designed to create seals when compressed within a groove. They function by filling the space between mating surfaces, thereby preventing the passage of fluids or gases. O Rings are effective in various applications due to their ability to conform to different surface irregularities and maintain a seal under pressure 1.

Role of the 4995093 O Ring Seal in Truck Operation

This Cummins part plays a specific role in the operation of commercial trucks by ensuring the sealing integrity of certain systems or components. It is commonly associated with fuel systems, where it helps to prevent fuel leaks and ensures that the fuel delivery system operates efficiently. Additionally, it may be used in other systems where fluid or gas sealing is required to maintain system performance and safety 2.

Key Features of the 4995093 O Ring Seal

The design and material characteristics of the 4995093 O Ring Seal contribute to its effectiveness and durability in heavy-duty applications. It is crafted from materials that offer resistance to a wide range of operating conditions, including temperature variations and exposure to various chemicals. Its design ensures a snug fit within the designated grooves, providing a reliable seal even under high pressure 3.

Benefits of Using the 4995093 O Ring Seal

The advantages provided by the 4995093 O Ring Seal include improved sealing performance, which helps in maintaining system efficiency and reducing the risk of leaks. Its durability ensures longevity, even in demanding operating environments. Additionally, its resistance to various operating conditions makes it a reliable choice for commercial truck applications 4.

Troubleshooting Common Issues with O Ring Seals

Identifying and addressing typical problems associated with O Ring Seals is important for maintaining vehicle performance. Signs of wear or failure may include leaks, reduced system efficiency, or physical damage to the seal. Corrective actions may involve inspecting the seal for damage, ensuring proper installation, and replacing the seal if necessary to restore system integrity.

Maintenance Practices for O Ring Seals

Regular inspection, care, and replacement of O Ring Seals are recommended to ensure optimal performance and longevity. Maintenance practices should include checking for signs of wear or damage, ensuring that seals are properly installed, and replacing seals according to the manufacturer’s recommendations or when signs of failure are observed.

Cummins: A Brief Overview

Cummins Inc. is a corporation known for its engines and related technologies, with a significant presence in the commercial truck industry. Founded in 1919, Cummins has a history of innovation and quality, offering a wide range of products designed to meet the needs of various industries. Its reputation in the commercial truck sector is built on a commitment to reliability, performance, and customer satisfaction.

Cummins Engine O Ring Seal 4995093 Compatibility

The O Ring Seal part number 4995093, manufactured by Cummins, is designed to fit a variety of Cummins engine models. This seal is crucial for ensuring that the engine operates efficiently by preventing leaks and maintaining the integrity of the system. Below is a detailed description of the engines with which this O Ring Seal is compatible.

ISC CM2150 and ISL CM2150

The O Ring Seal 4995093 is compatible with the ISC CM2150 and ISL CM2150 engines. These engines are known for their robust performance and reliability, often used in heavy-duty applications. The seal fits into the system where it is needed to prevent any fluid or gas leakage, ensuring the engine maintains optimal pressure and efficiency.

ISC8.3 CM2250 and ISL9 CM2250

The O Ring Seal 4995093 also fits the ISC8.3 CM2250 and ISL9 CM2250 engines. These engines are part of the next generation in Cummins’ lineup, offering improved performance and fuel efficiency. The seal is essential in these engines to maintain the integrity of the system and prevent any potential leaks that could compromise engine performance.

QSC9 CM2250/QSL9 CM2250

The O Ring Seal 4995093 is also compatible with the QSC9 CM2250 and QSL9 CM2250 engines. These engines are designed for demanding applications and are known for their durability and efficiency. The seal plays a critical role in maintaining the system’s integrity, ensuring that the engine operates at peak performance without any leaks.

QSL9 CM2250 and QSL9 CM2350 L102

Lastly, the O Ring Seal 4995093 fits the QSL9 CM2250 and QSL9 CM2350 L102 engines. These engines are part of the Cummins QSL series, known for their reliability and efficiency in various applications. The seal is essential in these engines to prevent leaks and maintain the system’s integrity, ensuring the engine operates efficiently and reliably.

By ensuring that the O Ring Seal 4995093 is properly installed in these engines, operators can maintain the performance and longevity of their equipment, preventing costly downtime and repairs.

Role of Part 4995093 O Ring Seal in Engine Systems

The 4995093 O Ring Seal is instrumental in maintaining the integrity and efficiency of various engine components. When integrated into the breather system, this seal ensures that air entering the crankcase is properly regulated, preventing contaminants from being drawn in while allowing excess pressure to be released. This balance is essential for maintaining optimal crankcase pressure, which in turn supports engine performance and longevity.

In the context of the crankcase, the O Ring Seal plays a significant role in sealing connections and joints. By providing a tight seal, it prevents oil leaks and ensures that the crankcase remains lubricated and free from external contaminants. This is particularly important in high-performance engines where precision and reliability are paramount.

When fitted within the oil separator breather system, the 4995093 O Ring Seal helps in separating oil vapors from the crankcase ventilation gases. This process is vital for maintaining clean air intake and reducing oil consumption. The seal ensures that the separated oil is effectively returned to the sump, rather than being expelled into the atmosphere, thus contributing to both engine efficiency and environmental compliance.

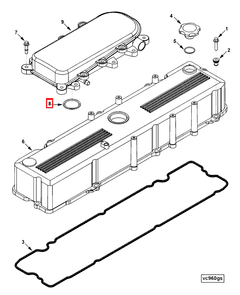

In valve cover applications, the O Ring Seal is used to create a secure barrier between the valve cover and the cylinder head. This seal is essential for preventing oil leaks, which can lead to decreased lubrication efficiency and potential engine damage. Additionally, it helps in maintaining the integrity of the PCV (Positive Crankcase Ventilation) system by ensuring that gases are properly routed and not allowed to escape into the engine compartment.

Overall, the 4995093 O Ring Seal is a fundamental component in ensuring the seamless operation of these engine systems, contributing to both performance and durability.

Conclusion

The Cummins 4995093 O Ring Seal is a vital component in the maintenance and operation of commercial trucks. Its role in preventing leaks, ensuring system efficiency, and maintaining the integrity of various engine systems cannot be overstated. Regular maintenance and proper installation of this part are essential for the longevity and performance of commercial vehicles.

-

Mom, G. (2023). The Evolution of Automotive Engineering: A Handbook. SAE International.

↩ -

Gillespie, T. D. (2021). Fundamentals of Vehicle Dynamics. SAE International.

↩ -

Zhao, H. (2010). Advanced Direct Injection Combustion Engine Technologies and Development Volume 2 Diesel Engines. CRC Press.

↩ -

Halderman, J. D. (2012). Automotive Principles: Diagnosis and Service. Prentice Hall.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.