5261587

O Ring Seal

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 5261587 O Ring Seal is a critical component designed to maintain the integrity of seals in various systems within commercial trucks. It plays a significant role in ensuring the efficiency and reliability of truck operations by preventing leaks and ensuring systems function as intended.

Basic Concepts of O Ring Seals

An O Ring Seal is a toroidal (ring-shaped) elastomer with a circular cross-section, used to create a seal between two or more parts. It operates by being compressed within a groove, forming a barrier that prevents the passage of fluids or gases. O Ring Seals are widely utilized in mechanical systems due to their simplicity, effectiveness, and versatility in creating reliable seals in a variety of applications 1.

Purpose of the Cummins 5261587 O Ring Seal

This Cummins part is specifically engineered to play a role in the sealing mechanisms of commercial trucks. It is associated with critical systems or components where maintaining a seal is necessary to ensure the proper operation of the truck. This includes applications where fluids or gases must be contained to prevent leaks, maintain pressure, or ensure the purity of the contained substances.

Key Features

The Cummins 5261587 O Ring Seal is characterized by its material composition, typically made from durable elastomers that offer resistance to a wide range of operating conditions. Its design is tailored to fit specific grooves and applications, ensuring a snug fit that enhances its sealing capabilities. Unique attributes may include resistance to extreme temperatures, chemicals, and abrasion, contributing to its performance and durability in demanding environments 2.

Benefits of Using the Cummins 5261587 O Ring Seal

Utilizing this part offers several advantages. It provides improved sealing efficiency, reducing the risk of leaks and ensuring that systems operate within their designed parameters. Its resistance to wear and tear extends the component’s lifespan, reducing the frequency of replacements. Additionally, its compatibility with specific truck models or engine types ensures that it meets the precise requirements of its intended applications.

Installation and Replacement Guidelines

Proper installation and replacement of this Cummins part require attention to detail and adherence to specific procedures. Tools required may include groove cleaners, lubricants compatible with the O Ring material, and possibly specialized installation tools to ensure the seal is properly seated without damage. Safety precautions include ensuring the work area is clean, the O Ring is free from contaminants, and that all mating surfaces are prepared to receive the new seal 3.

Troubleshooting Common Issues

Common problems associated with O Ring Seals in truck applications include leaks, seal failure due to wear or damage, and improper seating. Potential causes may range from incorrect installation to exposure to incompatible fluids or extreme operating conditions. Recommended troubleshooting steps include inspecting the seal and mating surfaces for damage, ensuring proper groove preparation, and verifying that the O Ring is correctly sized and installed for the application.

Maintenance Tips

To ensure the longevity and optimal performance of the Cummins 5261587 O Ring Seal, regular maintenance is advised. This includes periodic inspections for signs of wear or damage, cleaning the seal and its groove to remove contaminants, and replacing the seal according to the manufacturer’s recommendations or when signs of degradation are observed. Adhering to these practices helps maintain the seal’s effectiveness and contributes to the overall reliability of the truck’s systems.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability in the commercial truck industry. Its product range includes a variety of engines, components, and systems designed to meet the demanding requirements of commercial transportation, contributing to the efficiency, performance, and sustainability of its customers’ operations.

Cummins Engine O Ring Seal 5261587 Compatibility

This O Ring Seal is designed to fit a variety of Cummins engines, ensuring a secure seal in various applications. Below is a detailed breakdown of the engines with which this O Ring Seal is compatible:

- 15N CM2380 M104B

- B4.5 CM2350 B129B, ISB4.5 CM2350 B104

- D4.0 CM2620 D103B

- F3.8 CM2350 F120B, F3.8 CM2350 F128C, F3.8 CM2620 F137B

- F3.8 F102

- F4.5 CM2620 F139B, F4.5 CM2620 F141C

- ISF3.8 CM2220 AN, ISF3.8 CM2220 F103, ISF3.8 CM2350 F109, ISF4.5 CM2220 F123

- ISG11 CM2880 G108, ISG12 CM2880 G107

- QSF3.8 CM2350 F107, QSF3.8 CM2880 F112

- QSG12 CM2880 G112, QSG12/X12 CM2350 G110

- X12 CM2350 X119B, X12 CM2670 X121B, X13 CM2670 X122B

- Z14 CM2670 Z103B

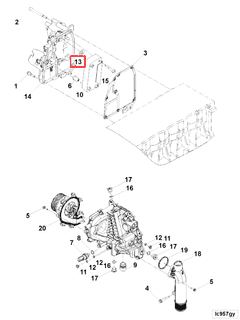

Role of Part 5261587 O Ring Seal in Engine Systems

The part 5261587 O Ring Seal is instrumental in ensuring the integrity and efficiency of various engine systems by providing reliable sealing solutions. In the context of an Engine Oil Cooler, the O Ring Seal is positioned to prevent leaks between the cooler and its housing, maintaining the necessary pressure and temperature conditions for optimal oil flow.

When integrated into an Engine Oil Cooling System, the O Ring Seal plays a significant role in the Lubricating Oil Cooler Module. Here, it ensures that the cooling process is efficient by sealing the connections between the cooler and other components, such as the Lubricating Oil Filter Head. This seal is vital for preventing any oil loss, which could lead to reduced lubrication efficiency and increased wear on engine components.

In the Lower Engine Gasket Kit and Lower Engine Gasket Set, the O Ring Seal is used to create a tight seal around various passages and connections. This is particularly important in areas where engine oil and coolant might interact, such as in the Oil Cooler Housing. The seal helps maintain the separation of these fluids, ensuring that the engine operates within specified parameters.

Furthermore, in the Lubricating Oil Cooler, the O Ring Seal is employed to secure the connections between the cooler and the engine’s oil passages. This ensures that the oil is effectively cooled before it is recirculated, contributing to the overall longevity and performance of the engine.

Overall, the part 5261587 O Ring Seal is a fundamental component in maintaining the seals across various engine systems, ensuring that fluids remain contained and systems operate efficiently.

Conclusion

The Cummins 5261587 O Ring Seal is a vital component in the maintenance and operation of commercial truck engines. Its role in preventing leaks, ensuring system efficiency, and contributing to the overall reliability of truck operations cannot be overstated. Proper installation, maintenance, and understanding of its compatibility with various Cummins engines are essential for maximizing its benefits and ensuring the longevity of the truck’s systems.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.