Introduction

The Cummins 5262739 O Ring Seal is a critical component for commercial trucks, designed to ensure reliable sealing in various systems and components. This seal is essential for maintaining the integrity of fluid systems, preventing leaks that could lead to system failures or inefficiencies 1.

Basic Concepts of O Ring Seals

An O Ring Seal is a type of gasket made from elastomers or rubber-like materials, designed to be seated in a groove and compressed during assembly to create a seal at the interface 2. Materials commonly used include nitrile rubber, silicone, and fluorocarbon, each offering different properties such as temperature resistance, chemical compatibility, and durability. The primary function of an O Ring Seal is to prevent the leakage of fluids and gases, ensuring the efficiency and safety of the system it is part of 3.

Role of the Cummins 5262739 O Ring Seal in Truck Operation

This Cummins part ensures the integrity of seals in various truck systems, including fuel systems, hydraulic systems, and engine components. By maintaining pressure and preventing leaks, it contributes to the efficient operation of these systems, ensuring that fluids are delivered where needed without loss, which is vital for the performance and reliability of the truck 4.

Key Features

The 5262739 is characterized by its design and material properties, crafted from materials that offer excellent resistance to the harsh conditions found in commercial truck environments. Its design ensures a snug fit in the designated grooves, providing a reliable seal. Additionally, it may feature unique characteristics such as anti-extrusion properties, which enhance its performance in dynamic applications.

Benefits

The benefits of the 5262739 include improved sealing efficiency, leading to better system performance and reduced maintenance needs. Its durability and resistance to various operating conditions contribute to the overall reliability of the truck’s systems. By preventing leaks, it helps maintain system pressures and efficiencies, which are crucial for the truck’s operation. Furthermore, its contribution to system reliability reduces the risk of unexpected failures, enhancing safety and operational uptime.

Troubleshooting and Maintenance

Common issues with O Ring Seals include wear, degradation due to exposure to chemicals or high temperatures, and improper installation. Troubleshooting involves inspecting the seal for signs of wear or damage, checking the groove for proper seating, and ensuring that the seal is made from a material compatible with the fluids and operating conditions it encounters. Maintenance practices include regular inspection for signs of wear, proper installation according to manufacturer guidelines, and replacement as needed to prevent leaks and system failures.

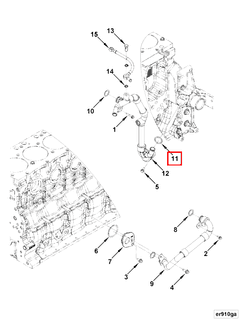

Compatibility with ISB (Chrysler) Engine

The 5262739 is designed to fit seamlessly within the ISB (Chrysler) engine series, ensuring a secure seal in various engine components and preventing leaks. This seal is engineered to withstand the high pressures and temperatures typical of engine environments, ensuring durability and reliability.

Role in Engine Systems

Exhaust Cooler Water Outlet Tube

The O Ring Seal is positioned at the connection points of the Exhaust Cooler Water Outlet Tube to prevent any leakage of coolant, ensuring that the coolant circulates effectively and maintaining optimal temperature levels.

Plumbing

Within the engine’s plumbing system, the O Ring Seal is used at various junctures where pipes and fittings connect, creating a watertight seal and preventing any fluid loss. This is particularly important in systems where precise fluid levels are necessary for the engine’s operation.

Exhaust Recirculation Water

In systems employing Exhaust Recirculation Water, the O Ring Seal ensures that the recirculated water does not escape, maintaining the intended flow and pressure within the system. This is key for efficient recirculation, which helps in reducing emissions and improving engine efficiency.

Conclusion

The Cummins 5262739 O Ring Seal plays a significant role in maintaining the operational integrity of engine components by ensuring tight seals, containing fluids, and allowing systems to operate within their designed parameters. Its design and material properties make it an essential part for the efficient and reliable operation of commercial trucks.

-

Giancarlo Genta and Lorenzo Morello, The Automotive Chassis Volume 1 Components Design Mechanical Engineering Series 2nd Edition, Springer, 2019.

↩ -

Moustafa ElGindy and Zeinab ElSayegh, Road and Off-Road Vehicle Dynamics, Springer Nature, 2023.

↩ -

Michael Hilgers and Wilfried Achenbach, Vocational Vehicles and Applications, Springer Vieweg, 2021.

↩ -

General Information, Bulletin Number 4021518, Operation and Maintenance Manual.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.