This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 5292106 O-Ring Seal, manufactured by Cummins, is a critical component in the commercial truck industry. This part is designed to ensure the integrity and efficiency of various systems within commercial trucks through effective sealing.

Basic Concepts of O-Ring Seals

An O-Ring Seal is a type of gasket with a circular cross-section, designed to create a seal between two or more parts. It operates by being compressed within a groove, allowing it to form a tight seal against the mating surface. O-Ring Seals are widely used in mechanical systems to prevent leaks of fluids and gases, ensuring the system operates efficiently and safely 1.

Purpose of the 5292106 O-Ring Seal in Truck Operations

The 5292106 O-Ring Seal plays a specific role in the operation of commercial trucks by ensuring the integrity of seals in various systems or components. It is typically associated with fuel systems, hydraulic systems, and other critical areas where fluid or gas containment is necessary. By maintaining these seals, the O-Ring contributes to the overall efficiency and reliability of the truck’s operation 2.

Key Features of the 5292106 O-Ring Seal

The 5292106 O-Ring Seal is characterized by its design and material properties, which include durability, resistance to a range of chemicals, and the ability to operate within a specified temperature range. These features make it particularly suitable for the demanding environments found in commercial truck applications 3.

Benefits of Using the 5292106 O-Ring Seal

Utilizing the 5292106 O-Ring Seal offers several advantages, such as improved system efficiency through reliable sealing, reduced maintenance needs due to its durability, and enhanced reliability in truck operations. These benefits contribute to the overall performance and longevity of the vehicle 4.

Installation Considerations

Proper installation of the 5292106 O-Ring Seal is vital for ensuring optimal performance and longevity. Guidelines and best practices for installation include ensuring the groove is clean and free of debris, using the correct installation tools to avoid damage, and verifying that the O-Ring is seated properly within the groove.

Troubleshooting Common Issues

Typical problems that may arise with O-Ring Seals include leaks or failures, which can often be traced back to installation errors, environmental factors, or wear and tear. Troubleshooting steps may involve inspecting the O-Ring and its groove for damage, ensuring proper installation, and considering replacement if necessary.

Maintenance Tips

Regular maintenance of the 5292106 O-Ring Seal is recommended to ensure continued performance. This includes periodic inspection for signs of wear or damage, cleaning the O-Ring and its groove as needed, and replacing the O-Ring according to the manufacturer’s guidelines or when signs of degradation are observed.

Cummins: Manufacturer Overview

Cummins is a reputable manufacturer with a long history in the commercial truck industry. Known for their quality and innovation, Cummins offers a wide range of products designed to enhance the performance, efficiency, and reliability of commercial trucks. Their commitment to excellence is reflected in the design and manufacturing of components like the 5292106 O-Ring Seal.

Cummins O-Ring Seal 5292106 Compatibility

The Cummins O-Ring Seal part number 5292106 is designed to fit a variety of Cummins engines, ensuring a reliable seal in critical areas. This O-Ring is engineered to meet the stringent requirements of Cummins’ engine designs, providing durability and performance across different applications.

ISB/ISD Series

The ISB/ISD series engines, including the ISB/ISD4.5 CM2150 B119, ISB3.9 CM2220 B107, ISB5.9 CM2880 B127, and ISBE CM2150, benefit from the 5292106 O-Ring Seal. This part is crucial in maintaining the integrity of the engine’s sealing systems, ensuring that there are no leaks and that the engine operates efficiently.

ISBE4 Series

The ISBE4 CM850 engine also utilizes the 5292106 O-Ring Seal. This engine, known for its robust performance, requires high-quality seals to maintain its operational standards. The O-Ring ensures that the engine’s components remain sealed, preventing any contamination or loss of pressure.

ISF Series

The ISF3.8 CM2220 AN and ISF4.5 CM2220 F123 engines are designed to work seamlessly with the 5292106 O-Ring Seal. These engines, often used in demanding applications, rely on this seal to maintain their efficiency and reliability. The O-Ring’s precision fit ensures that the engine’s performance is not compromised.

ISG Series

The ISG11 CM2880 G108 and ISG12 CM2880 G107 engines are part of the ISG series, which also incorporates the 5292106 O-Ring Seal. These engines, known for their power and efficiency, require seals that can withstand high pressures and temperatures. The O-Ring provides the necessary sealing to ensure optimal engine performance.

ISL Series

The ISL9 CM2150 SN and ISL9.5 CM2880 L138 engines are designed to use the 5292106 O-Ring Seal. These engines, often used in heavy-duty applications, need reliable seals to maintain their performance. The O-Ring ensures that the engine’s components remain sealed, preventing any leaks or contamination.

ISZ Series

The ISZ13 CM2150 Z105 engine also utilizes the 5292106 O-Ring Seal. This engine, known for its versatility, requires seals that can adapt to various conditions. The O-Ring provides the necessary sealing to ensure that the engine operates efficiently and reliably.

Role of Part 5292106 O-Ring Seal in Engine Systems

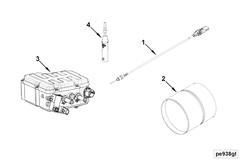

The part 5292106 O-Ring Seal is integral to maintaining the integrity and efficiency of various engine components. In the Air Control Valve, the O-Ring Seal ensures a tight seal between the valve body and its housing, preventing air leaks that could disrupt the air-fuel mixture.

Within the Aftertreatment System, specifically in the Diesel Exhaust Fluid (DEF) Tank and the Doser Fluid Supply Module, the O-Ring Seal plays a significant role. It secures connections and joints, ensuring that DEF is delivered without contamination or loss, which is essential for the reduction of emissions.

In the Plumbing of engine systems, the O-Ring Seal is used in conjunction with Male Unions to create leak-proof connections. This is particularly important in high-pressure systems where even minor leaks can lead to significant performance issues.

The O-Ring Seal is also vital in the Turbocharger system. It is employed in various joints and connections to maintain the turbocharger’s efficiency by preventing oil leaks and ensuring that the turbocharger operates within its designed parameters.

Additionally, in components like the Lever and Rocker mechanisms, the O-Ring Seal helps in maintaining the precision of movements by ensuring that lubricants remain within the intended pathways, reducing wear and tear on moving parts.

Overall, the part 5292106 O-Ring Seal is a fundamental component in ensuring the reliability and performance of these engine systems by providing essential seals in critical junctions and connections.

Conclusion

The 5292106 O-Ring Seal by Cummins is a vital component in the commercial truck industry, ensuring the integrity and efficiency of various systems within commercial trucks. Its design and material properties make it suitable for demanding environments, contributing to the overall performance and longevity of the vehicle. Proper installation, maintenance, and troubleshooting are essential to maximize the benefits of this Cummins part.

-

Hick, Hannes, Klaus Kupper, and Helfried Sorger. Systems Engineering for Automotive Powertrain Development. Springer, 2021.

↩ -

Hilgers, Michael. Chassis and Axles. Springer Vieweg, 2023.

↩ -

Composite Materials Handbook Volume 4 Metal Matrix Composites. SAE International, 2013.

↩ -

Minaker, Bruce P. Fundamentals of Vehicle Dynamics and Modelling. John Wiley Sons, 2019.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.