3080769

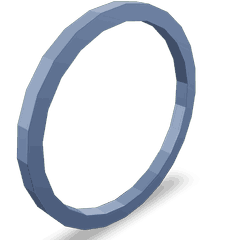

Rectangular Ring Seal

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

Minimum Quantity 2

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction to Rectangular Ring Seals

A rectangular ring seal, such as the Cummins part #3080769, is a vital component in the operation of commercial trucks and heavy-duty vehicles. These seals are designed to prevent the leakage of fluids and gases, ensuring the efficiency and longevity of the engine. Understanding the fundamental concepts of how these seals work is essential for engineers, mechanics, truck drivers, and fleet operators 1.

How a Rectangular Ring Seal Works

The rectangular ring seal operates by creating a tight barrier between two surfaces, typically in the engine’s cylinder block or other critical areas. The seal is made from high-performance elastomeric materials that can withstand extreme temperatures, pressures, and chemical exposure. When installed correctly, the seal forms a reliable barrier that prevents the escape of fluids and gases, maintaining the integrity of the engine’s internal systems 2.

Purpose of the Cummins Rectangular Ring Seal Part #3080769

The Cummins part #3080769 rectangular ring seal plays a vital role in the operation of commercial trucks. Its primary function is to ensure that the engine’s internal components remain sealed, preventing oil, coolant, and other fluids from leaking out. This seal is particularly important in high-pressure environments, such as the cylinder block, where even a small leak can lead to significant performance issues and potential engine damage 3.

Importance in Truck Operations

In the context of truck operations, the rectangular ring seal is essential for maintaining engine efficiency and reliability. A compromised seal can lead to oil leaks, coolant loss, and other issues that can affect the truck’s performance and safety. Regular maintenance and inspection of these seals are critical to ensuring that the truck operates at peak efficiency and to avoid costly repairs 4.

Troubleshooting and Maintenance

Proper maintenance of the rectangular ring seal is crucial to its longevity and effectiveness. Here are some troubleshooting and maintenance tips:

-

Regular Inspections: Regularly inspect the seal for signs of wear, cracks, or deformation. Any visible damage should be addressed immediately to prevent leaks.

-

Clean Installation: Ensure that the seal is installed correctly and that the mating surfaces are clean and free of debris. A clean installation is critical to the seal’s performance.

-

Proper Torque: When installing the seal, use the manufacturer’s recommended torque settings to avoid over-tightening, which can damage the seal, or under-tightening, which can lead to leaks.

-

Replacement: If the seal shows signs of wear or damage, replace it promptly. Using a high-quality replacement part, such as the Cummins part #3080769, is essential to maintaining the seal’s integrity.

Cummins: A Leader in Engine Technology

Cummins is a renowned manufacturer of engines and related components for commercial trucks and heavy-duty vehicles. With a history of innovation and reliability, Cummins products are trusted by fleet operators worldwide. The Cummins part #3080769 rectangular ring seal is a testament to the company’s commitment to quality and performance, providing a reliable solution for sealing critical engine components.

Compatibility with Cummins Engines

The Rectangular Ring Seal part number 3080769, manufactured by Cummins, is designed to fit seamlessly with a variety of Cummins engines. This seal is crucial for maintaining the integrity of the engine’s sealing system, ensuring optimal performance and longevity.

ISM Series Engines

The Rectangular Ring Seal part 3080769 is compatible with the following ISM series engines:

- ISM CM570

- ISM CM570/870

- ISM CM876

- ISM11 CM876 SN

- QSM11 CM570

- QSM11 CM876

These engines, part of the ISM series, are known for their robust performance and reliability, often used in heavy-duty applications. The seal ensures that these engines maintain their efficiency and durability by preventing leaks and maintaining pressure.

M11 Series Engines

The seal also fits the following M11 series engines:

- M11 CELECT

- M11 CELECT PLUS

- M11 MECHANICAL

The M11 series engines are designed for versatility and efficiency, suitable for a range of applications from construction to transportation. The Rectangular Ring Seal part 3080769 is essential in these engines to maintain their operational integrity.

L10 GAS Engine

Lastly, the Rectangular Ring Seal part 3080769 is also compatible with the L10 GAS engine. This engine is known for its high power output and efficiency, often used in demanding applications. The seal ensures that the engine operates smoothly and reliably by preventing any potential leaks.

Role of Part 3080769 Rectangular Ring Seal in Engine Systems

The Part 3080769 Rectangular Ring Seal is integral to the efficient operation of various engine components. Its primary function is to ensure a secure and leak-proof seal between mating surfaces, which is essential for maintaining the integrity of the engine’s fluid systems.

Integration with Key Components

-

Cylinder Block and Head: The Rectangular Ring Seal is often used in conjunction with the cylinder block and head to prevent oil and coolant leaks. By providing a tight seal, it ensures that these fluids remain within their designated pathways, thus maintaining optimal engine performance and preventing contamination.

-

Lower Engine Gasket Set: When integrated with the lower engine gasket set, the Rectangular Ring Seal enhances the gasket’s ability to seal gaps between the cylinder block and other engine components. This is particularly important in high-pressure areas where even minor leaks can lead to significant performance issues.

-

Oil Filter Cooler: In oil filter coolers, the seal plays a vital role in maintaining the pressure differential required for efficient oil cooling. It ensures that oil flows smoothly through the cooler without any bypass, which could compromise the cooling efficiency and lead to overheating.

-

Oil Cooler Kit: Within an oil cooler kit, the Rectangular Ring Seal is used to seal connections between the oil cooler and the engine’s oil passages. This ensures that the oil is effectively cooled before returning to the engine, thereby prolonging the engine’s lifespan and enhancing its reliability.

-

Overhaul Kit: During engine overhauls, the Rectangular Ring Seal is a common component in overhaul kits. It is used to replace worn-out seals, ensuring that the refurbished engine operates as efficiently as a new one. This is particularly important in maintaining the engine’s compression and preventing oil leaks.

-

Plumbing and Oil Cooler Water Connections: In the plumbing of oil coolers that use water as a cooling medium, the seal ensures that there are no leaks between the oil and water circuits. This is essential for maintaining the efficiency of the cooling process and preventing cross-contamination between the oil and water systems.

-

Engine Oil System: Overall, the Rectangular Ring Seal is a key component in the engine oil system, ensuring that oil remains within its intended pathways. This is essential for lubrication, cooling, and cleaning within the engine, all of which are fundamental to the engine’s operation and longevity.

Conclusion

The Cummins part #3080769 rectangular ring seal is an essential component in the operation of commercial trucks. Understanding its function, importance, and maintenance requirements is crucial for ensuring the engine’s efficiency and reliability. By following proper maintenance practices and using high-quality replacement parts, engineers, mechanics, truck drivers, and fleet operators can help ensure that their vehicles perform at their best.

-

Randall, Martynn. Haynes Manual on Diesel Engines. Haynes Publishing, 2015.

↩ -

Aird, Forbes. Bosch Fuel Injection Systems. HP Books, 2001.

↩ -

Brach, R. Matthew. SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE Books, 2023.

↩ -

Reif, Konrad Ed. Brakes Brake Control and Driver Assistance Systems Function Regulation and Components. Springer, 2014.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.