4076823

Rectangular Ring Seal

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 4076823 Rectangular Ring Seal is a specialized component designed for use in commercial trucks. Its primary function is to provide a reliable seal in various mechanical systems, ensuring the integrity of the system by preventing leaks and maintaining pressure. This seal is particularly important in environments where durability and performance under stress are paramount 1.

Basic Concepts of Rectangular Ring Seals

A Rectangular Ring Seal is a type of gasket commonly used in mechanical systems to create a seal between two or more parts. These seals are typically made from elastomeric materials, which allow them to conform to the surfaces they are sealing against. They function by being compressed between the mating surfaces, which creates a barrier that prevents the passage of fluids or gases. Rectangular Ring Seals are widely used in applications where a robust and reliable seal is required, such as in engines, transmissions, and hydraulic systems 2.

Purpose of the Cummins 4076823 Rectangular Ring Seal

The Cummins 4076823 Rectangular Ring Seal plays a significant role in the operation of commercial trucks by ensuring the integrity of seals within the engine or transmission system. It is designed to withstand high pressures and temperatures, which are common in these applications. By providing a reliable seal, it helps maintain the efficiency and performance of the truck’s mechanical systems 3.

Key Features

The Cummins 4076823 Rectangular Ring Seal is characterized by several key features that enhance its performance. It is made from high-quality elastomeric materials that offer excellent resistance to wear and tear. The design of the seal allows it to conform to irregular surfaces, ensuring a tight seal. Additionally, it features a rectangular cross-section, which provides a larger sealing area compared to traditional O-rings, enhancing its effectiveness in high-pressure applications.

Benefits

Using the Cummins 4076823 Rectangular Ring Seal offers several advantages. It provides improved sealing performance, which is crucial in preventing leaks and maintaining system pressure. The seal’s durability ensures long-lasting performance, even in demanding conditions. Its reliability makes it a preferred choice for heavy-duty applications, where consistent performance is essential.

Installation Process

Proper installation of the Cummins 4076823 Rectangular Ring Seal is crucial for ensuring its effectiveness. The installation process involves cleaning the mating surfaces to remove any debris or contaminants. The seal should be lubricated before installation to facilitate easy placement and to prevent damage. It is important to ensure that the seal is properly seated and that there is no excessive compression, which could lead to seal failure.

Troubleshooting Common Issues

Common issues with Rectangular Ring Seals include leaks and seal failure. These problems can often be traced back to improper installation, contamination of the seal or mating surfaces, or excessive compression. Troubleshooting these issues involves inspecting the seal and mating surfaces for damage or contamination, ensuring proper installation techniques are used, and verifying that the seal is not over-compressed.

Maintenance Tips

To ensure the longevity and optimal performance of the Cummins 4076823 Rectangular Ring Seal, regular maintenance is recommended. This includes periodic inspection of the seal for signs of wear or damage. Replacement guidelines should be followed to ensure that the seal is replaced before it fails. Keeping the mating surfaces clean and free of contaminants will also help maintain the integrity of the seal.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins is committed to quality and innovation, providing reliable and efficient solutions for the automotive and heavy-duty truck industry. Their products are known for their durability, performance, and efficiency, making them a trusted choice for commercial applications.

Cummins Rectangular Ring Seal Part 4076823 Compatibility

The Cummins Rectangular Ring Seal part number 4076823 is designed to fit a variety of Cummins engines, ensuring a secure seal to prevent leaks and maintain optimal performance. Below is a detailed breakdown of the engines with which this part is compatible:

15N Series

- 15N CM2380 M104B

B4.5 Series

- B4.5 CM2350 B129B

- ISB4.5 CM2350 B104

B6.7 Series

- B6.7 CM2350 B135B

- ISB6.7 CM2250

- ISB6.7 CM2350 B101

- ISB6.7 G CM2180 B118

F3.8 Series

- F3.8 CM2350 F128C

- ISF3.8 CM2220 F103

ISB Series

- ISB CM2150

- ISB CM850

- ISB/ISD4.5 CM2150 B119

- ISB6.7 CM2150

- ISB6.7 CM2350 B101

- ISB6.7 G CM2180 B118

ISC Series

- ISC CM2150

- ISC CM850

- ISL CM2150

- ISL G CM2180

- ISL9 CM2150 SN

- ISL9 CM2250

ISBE Series

- ISBE4 CM850

ISM Series

- ISM CM570/870

- ISM CM876

ISV Series

- ISV (Nissan)

ISX Series

- ISX CM870

ISD Series

- ISD4.5 CM2220 D108

This compatibility ensures that the Rectangular Ring Seal part number 4076823 can be used across a wide range of Cummins engines, providing a reliable sealing solution for various applications.

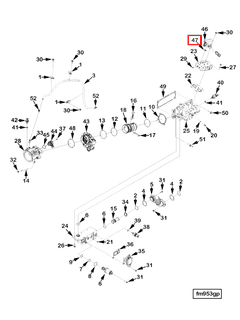

Role of Part 4076823 Rectangular Ring Seal in Engine Systems

The 4076823 Rectangular Ring Seal is an essential component in various engine systems, ensuring the integrity and efficiency of several critical functions.

Aftercooler Gasket Kit

In the aftercooler gasket kit, the 4076823 Rectangular Ring Seal provides a reliable seal between the aftercooler and its housing. This ensures that the compressed air is effectively cooled before entering the engine, maintaining optimal performance and efficiency.

Aftertreatment Device

Within the aftertreatment device, the seal plays a role in maintaining the airtight integrity of the system. This is vital for the effective reduction of emissions, as any leaks could compromise the efficiency of the aftertreatment processes.

Air Flow Metering Orifice

The seal is used in the air flow metering orifice to ensure accurate air measurement. Precise air flow data is essential for the Engine Control Module (ECM) to make correct fuel delivery decisions, thus optimizing engine performance.

Air Intake Connection

In the air intake connection, the 4076823 Rectangular Ring Seal ensures a secure fit, preventing air leaks that could affect the air-fuel ratio and engine performance.

Assembly Sensor

When integrated into an assembly sensor, the seal helps maintain the sensor’s accuracy by preventing contaminants from entering the sensing area, thus ensuring reliable data collection.

Catalytic Converter

In the catalytic converter, the seal ensures that exhaust gases pass through the converter efficiently, enhancing the reduction of harmful emissions.

Differential Pressure Sensor

The seal is crucial in the differential pressure sensor to maintain accurate pressure readings. This is important for monitoring various engine parameters and ensuring optimal performance.

Engine Control Module (ECM)

Although not directly part of the ECM, the seal is used in components connected to the ECM, such as sensors and actuators, to ensure they function correctly and provide accurate data.

Exhaust Recirculation (EGR)

In the EGR system, the seal ensures that recirculated exhaust gases are properly metered and introduced into the intake stream, helping to reduce NOx emissions.

Exhaust Recirculation Air Arrangement and Plumbing

The seal is utilized in the EGR air arrangement and plumbing to maintain a leak-free system, ensuring that the recirculated exhaust gases are effectively managed.

Fuel Control and Fuel Control Module

In fuel control systems, the seal ensures that fuel lines and connections remain intact, preventing leaks and maintaining the precise delivery of fuel to the engine.

Hardware Kit

In various hardware kits, the seal is used to ensure that all connections are secure and leak-free, contributing to the overall reliability of the engine system.

Intake Manifold Cover

The seal is employed in the intake manifold cover to ensure a tight fit, preventing air leaks that could affect engine performance and efficiency.

Pressure Sensor

In pressure sensors, the seal helps maintain accurate pressure readings by preventing leaks and contamination, ensuring the sensor provides reliable data to the ECM.

Sensor Kit

Within sensor kits, the seal is used to ensure that sensors are properly sealed, maintaining their accuracy and reliability in measuring various engine parameters.

Throttle Valve

The seal is utilized in the throttle valve to ensure a secure fit, preventing air leaks that could affect the air-fuel ratio and engine performance.

Conclusion

The Cummins 4076823 Rectangular Ring Seal is a critical component in ensuring the reliability and efficiency of commercial truck engines. Its robust design, durability, and compatibility with a wide range of Cummins engines make it an essential part for maintaining the integrity of various engine systems. Proper installation, regular maintenance, and understanding its role in different engine components are key to maximizing its performance and longevity.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.