5307960

Rectangular Ring Seal

Cummins®

IN STOCK

8 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 5307960 Rectangular Ring Seal is a component manufactured by Cummins, a well-established name in the commercial truck industry. This seal is designed for use in commercial trucks, where it contributes to the efficient operation of the vehicle’s engine or transmission system. Cummins is renowned for its commitment to quality and innovation, making the 5307960 Rectangular Ring Seal a reliable choice for heavy-duty applications 1.

Basic Concepts of Rectangular Ring Seals

A Rectangular Ring Seal is a type of gasket used in mechanical systems to create a seal between two surfaces. It functions by filling the gap between mating surfaces, preventing the leakage of fluids or gases. These seals are commonly used in applications where a high degree of sealing performance is required, such as in engines and transmissions 2. The rectangular shape of the seal allows it to maintain a consistent sealing pressure across the entire surface area, ensuring effective sealing under various operating conditions.

Purpose of the 5307960 Rectangular Ring Seal

The 5307960 Rectangular Ring Seal plays a role in the operation of a truck by providing a reliable seal within the engine or transmission system. Its primary function is to prevent the leakage of fluids, such as oil or coolant, which are vital for the proper functioning of the engine and transmission. By maintaining a secure seal, the 5307960 Rectangular Ring Seal helps to ensure that these fluids remain within their designated pathways, contributing to the overall efficiency and reliability of the truck’s powertrain 3.

Key Features

The 5307960 Rectangular Ring Seal is characterized by several key features that enhance its performance and durability. It is made from high-quality materials that are resistant to wear and corrosion, ensuring long-lasting service in demanding environments. The design of the seal includes precise dimensions and tolerances to ensure a perfect fit within the engine or transmission system. Additionally, the seal may feature unique attributes such as anti-extrusion properties, which help to prevent the seal from being forced out of its groove under high pressure 4.

Benefits

Using the 5307960 Rectangular Ring Seal offers several advantages in heavy-duty applications. The seal provides improved sealing performance, effectively preventing leaks and maintaining the integrity of the engine or transmission system. Its durable construction ensures reliability over time, reducing the need for frequent replacements. Furthermore, the seal’s design contributes to the overall efficiency of the truck by ensuring that critical fluids remain within their designated pathways, supporting optimal engine and transmission operation 5.

Installation Process

Proper installation of the 5307960 Rectangular Ring Seal is crucial for ensuring its effectiveness and longevity. The installation process involves several steps: First, the mating surfaces must be cleaned and inspected for any damage or irregularities. Next, the seal should be carefully placed into its designated groove, ensuring that it is seated correctly and evenly. Tools such as seal installation tools may be required to properly position the seal without damaging it. Finally, the components should be reassembled, taking care to follow the manufacturer’s guidelines for torque specifications and assembly procedures 6.

Troubleshooting Common Issues

Common problems associated with Rectangular Ring Seals include leaks, seal extrusion, and premature wear. To address these issues, it is important to conduct a thorough inspection of the seal and its mating surfaces. If a leak is detected, the seal may need to be replaced. Seal extrusion can often be prevented by ensuring that the seal is properly installed and that the mating surfaces are free of defects. Premature wear may indicate that the seal is not compatible with the operating conditions or that there are underlying issues within the engine or transmission system that need to be addressed 7.

Maintenance Tips

To ensure the longevity and optimal performance of the 5307960 Rectangular Ring Seal, regular maintenance is recommended. This includes periodic inspection of the seal and its mating surfaces for signs of wear, damage, or leaks. Replacement guidelines should be followed to ensure that the seal is replaced before it reaches the end of its service life. Additionally, keeping the engine and transmission system clean and well-lubricated can help to reduce wear on the seal and extend its lifespan 8.

Cummins: Manufacturer Overview

Cummins is a leading manufacturer in the commercial truck industry, known for its commitment to quality, innovation, and customer satisfaction. With a rich history of producing reliable and high-performance components, Cummins has established a strong reputation among truck operators and maintenance professionals. The company’s dedication to research and development ensures that its products, including the 5307960 Rectangular Ring Seal, meet the demanding requirements of modern commercial trucks. Cummins’ focus on quality control and continuous improvement underscores its position as a trusted provider of commercial truck components 9.

Cummins Rectangular Ring Seal 5307960 Compatibility

The Cummins Rectangular Ring Seal part number 5307960 is a critical component designed to ensure proper sealing in various engine configurations. This part is compatible with a wide range of Cummins engines, including:

- 4B3.9

- 6B5.9

- B4.5 CM2350 B129B

- B5.9 GAS PLUS CM556

- B6.7 CM2350 B135B

- B6.7 CM2670 B153B

- B6.7 G CMOH6.0 B125

- F3.8 CM2620 F137B

- F4.5 CM2620 F139B

- ISB/ISD4.5 CM2150 B119

- ISB/ISD6.7 CM2150 SN

- ISB4.5 CM2350 B104

- ISB5.9 CM2880 B110

- ISB5.9 CM2880 B140

- ISB5.9 CM2880 B149

- ISB5.9G CM2180

- ISB6.7 G CM2180 B118

- ISBE CM2150

- ISBE CM800

- ISBE4 CM850

- ISD4.5 CM2220 D108

- ISF2.8 CM2220 F129

- ISF3.8 CM2220 AN

- QSB4.5 CM850(CM2850)

- QSB6.7 CM2250

This seal is engineered to fit seamlessly into the specified engine models, ensuring optimal performance and longevity. It is essential for maintaining the integrity of the engine’s sealing system, preventing leaks, and ensuring efficient operation 10.

Role of Part 5307960 Rectangular Ring Seal in Engine Systems

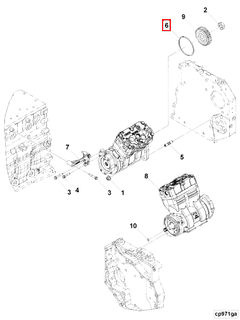

The 5307960 Rectangular Ring Seal is integral to the efficient operation of various engine components. In an Air Compressor Kit, it ensures a tight seal between the compressor and the cylinder block, preventing air leaks that could reduce efficiency.

When integrated into a Complete Engine Gasket Kit or a Full Engine Gasket Set, this seal plays a significant role in maintaining the integrity of the engine’s sealing system. It is particularly important in the Lower Engine Gasket Kit and Lower Engine Gasket Set, where it helps to seal the lower portions of the engine, ensuring that no gases escape and that the engine operates smoothly.

In the context of an Overhaul Kit, the 5307960 Rectangular Ring Seal is often included to replace worn or damaged seals, contributing to the restoration of the engine’s performance. It is also a component in the Upper Engine Gasket Kit, assisting in sealing the upper engine components, which is essential for maintaining compression and preventing leaks.

For Engine Installation Kits and Seal Kits, this rectangular ring seal is a fundamental part, ensuring that all connections are secure and leak-free. It is also utilized in Auxiliary Pump systems to maintain the seal integrity of the pump components.

In summary, the 5307960 Rectangular Ring Seal is a versatile component that enhances the functionality and reliability of various engine systems by providing essential sealing capabilities 11.

Conclusion

The 5307960 Rectangular Ring Seal is a critical component in the operation of commercial trucks, ensuring the efficient and reliable sealing of engine and transmission systems. Its high-quality construction, precise design, and compatibility with a wide range of Cummins engines make it an essential part for maintaining the integrity and performance of heavy-duty applications. Proper installation, regular maintenance, and timely replacement are key to maximizing the benefits of this Cummins part.

-

Hilgers, Michael. Vocational Vehicles and Applications. Springer Nature, 2023.

↩ -

Williams, Daniel. Generalized Vehicle Dynamics. SAE International, 2022.

↩ -

Hilgers, Michael. Transmissions and Drivetrain Design. Springer Vieweg, 2022.

↩ -

Awari, G.K., Kumbhar, V.S., and Tirpude, R.B. Automotive Systems Principles and Practice. CRC Press, 2011.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 2883648, Engine: QSB3.3 CM2250 EC.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 2883648, Engine: QSB3.3 CM2250 EC.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 2883648, Engine: QSB3.3 CM2250 EC.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 2883648, Engine: QSB3.3 CM2250 EC.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 2883648, Engine: QSB3.3 CM2250 EC.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 2883648, Engine: QSB3.3 CM2250 EC.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 2883648, Engine: QSB3.3 CM2250 EC.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.