S1070

Grommet Seal

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

Minimum Quantity 2

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The S1070 Grommet Seal, manufactured by Cummins, is a component designed for use in commercial trucks. Cummins, a well-established name in the commercial truck industry, produces a range of parts that contribute to the efficiency and reliability of truck operations. Seals, such as the S1070, play a significant role in maintaining the integrity of various systems within heavy-duty trucks by preventing leaks and protecting cables or pipes 1.

Basic Concepts of Grommet Seals

Grommet seals are components used in mechanical systems to provide a seal around cables, wires, or pipes that pass through openings. Their primary function is to prevent the ingress of dust, moisture, and other contaminants, while also offering protection to the cables or pipes from abrasion and physical damage. Grommet seals operate by creating a tight fit around the passing elements, ensuring a secure and durable seal 2.

Purpose of the S1070 Grommet Seal

The S1070 is specifically designed to serve within the operational systems of a truck. It is placed in areas where cables or pipes need protection and sealing, such as around the engine compartment or within the chassis. By doing so, the seal contributes to the overall functionality and longevity of the truck’s systems, ensuring that sensitive components remain protected from environmental factors.

Key Features

The S1070 is characterized by several key features that enhance its durability and effectiveness. It is composed of materials that offer resistance to wear and environmental conditions. The design of the seal includes elements that ensure a snug fit around cables or pipes, maximizing its sealing capabilities. Additionally, the seal may possess unique characteristics that differentiate it from other seals, such as enhanced flexibility or resistance to specific chemicals.

Benefits

The implementation of the S1070 in truck systems offers several benefits. It contributes to improved system reliability by ensuring that cables and pipes remain sealed and protected. This results in reduced maintenance needs, as the seal helps prevent issues that could arise from leaks or damage to these components. Furthermore, the seal enhances the performance of the truck’s components by maintaining the integrity of the systems in which it is installed.

Installation Considerations

When installing the S1070, it is important to follow guidelines and best practices to ensure proper functionality. Preparation steps may include cleaning the area where the seal will be installed and ensuring that the cable or pipe is free from damage. The tools required for installation will depend on the specific application, but may include basic hand tools. Common pitfalls to avoid during installation include over-tightening the seal, which could lead to damage, and improper alignment, which could compromise the seal’s effectiveness.

Troubleshooting and Maintenance

To troubleshoot common issues related to the S1070, it is important to regularly inspect the seal for signs of wear or damage. Maintenance tips to prolong the lifespan of the seal include keeping the area around the seal clean and free from debris that could cause abrasion. Signs that the seal may need replacement include visible cracks, a loose fit around the cable or pipe, or evidence of leaks.

Common Applications

The S1070 finds applications in various truck systems, demonstrating its versatility and importance in different operational contexts. Typical applications include sealing and protecting cables or pipes in the engine compartment, within the chassis, or in other areas where environmental protection is required. Its use in these applications highlights the seal’s role in ensuring the reliable operation of truck systems.

About Cummins

Cummins Inc. is a leading manufacturer in the commercial truck industry, with a history of producing high-quality components that enhance the performance and reliability of trucks. The company’s product range includes a variety of parts designed to meet the demands of heavy-duty truck operations. Cummins’ reputation in the industry is built on its commitment to quality, innovation, and customer satisfaction, making it a trusted source for truck components.

Engine Compatibility with Grommet Seal S1070

The Grommet Seal S1070, manufactured by Cummins, is a crucial component designed to ensure a secure and leak-proof seal in various engine systems. This part is compatible with a wide range of Cummins engines, providing essential sealing functionality across multiple engine models.

ISB/ISD Series

- ISB/ISD4.5 CM2150 B119

- ISB/ISD6.7 CM2150 SN

These engines benefit from the S1070 seal, which helps maintain the integrity of the engine’s sealing system, ensuring optimal performance and longevity.

ISBE Series

- ISBE CM2150

- ISBE CM800

- ISBE4 CM850

The ISBE series engines utilize the S1070 seal to prevent leaks and maintain pressure within the engine, contributing to their overall efficiency and reliability.

ISC Series

- ISC CM850

The ISC CM850 engine incorporates the S1070 seal to ensure that all moving parts are properly sealed, reducing the risk of oil or fluid leaks.

ISD Series

- ISD4.5 CM2220 D108

This engine model relies on the S1070 seal to maintain the necessary seals for its operation, ensuring that the engine runs smoothly and efficiently.

ISL Series

- ISL9 CM2150 SN

The ISL9 CM2150 SN engine uses the S1070 seal to provide a reliable seal in critical areas, enhancing the engine’s performance and durability.

ISZ Series

- ISZ13 CM2150 Z105

The ISZ13 CM2150 Z105 engine incorporates the S1070 seal to ensure that all components are properly sealed, preventing leaks and maintaining engine efficiency.

QSB Series

- QSB4.5 CM850 (CM2850)

- QSB6.7 CM850 (CM2850)

- QSB7 CM2880 B117

These engines use the S1070 seal to maintain critical seals, ensuring that the engine operates at peak efficiency and reliability.

QSK Series

- QSK19 CM2350 K114

- QSK19 CM2350 K144G

- QSK19 CM500

- QSK19 CM850 MCRS

- QSK19G

- QSK45 CM500

- QSK60 CM500

- QSK60G

The QSK series engines rely on the S1070 seal to maintain essential seals, ensuring that the engine operates efficiently and reliably.

KTA Series

- KTA19

- KTA19GC

- KTA19GC CM558

These engines use the S1070 seal to ensure that all moving parts are properly sealed, contributing to the engine’s overall performance and longevity.

K19

The K19 engine incorporates the S1070 seal to maintain the necessary seals for its operation, ensuring that the engine runs smoothly and efficiently.

Role of Part S1070 Grommet Seal in Engine Systems

The S1070 is an essential component in various engine systems, ensuring the integrity and efficiency of fluid and gas pathways. Its application spans across multiple subsystems, contributing to the overall performance and reliability of the engine.

Compressor Water Outlet Tube

In the compressor water outlet tube system, the S1070 provides a secure and leak-proof connection between the tube and the compressor housing. This seal prevents water leakage, which could otherwise lead to compressor inefficiencies and potential damage.

Engine Installation Kit

Within the engine installation kit, the Grommet Seal is used to connect various plumbing components to the engine block. This ensures that all fluid pathways, such as coolant and lubrication lines, are properly sealed, maintaining the engine’s operational integrity.

Fuel Drain Tube

For the fuel drain tube, the S1070 creates a tight seal at connection points, preventing fuel leaks. This is vital for safety and ensures that the fuel system operates efficiently without contamination or loss of fuel.

Governor and Air Compressor

In the governor and air compressor systems, the Grommet Seal is employed to seal connections in the air and fluid lines. This helps in maintaining consistent pressure and flow, which is essential for the accurate operation of the governor and the efficiency of the air compressor.

Lubricating Oil Supply Tube

The Grommet Seal in the lubricating oil supply tube system ensures that oil flows smoothly and without leaks to all moving parts of the engine. This is important for reducing friction and wear, thereby extending the engine’s lifespan.

Painted Water Pump and Water Top Level Assembly Pump

For both the painted water pump and the water top level assembly pump, the Grommet Seal is used to ensure that water connections are secure. This prevents leaks and ensures efficient cooling of the engine.

Plumbing Systems

Across various plumbing systems, including those for auxiliary cooling, compressor coolant, engine monitoring, turbocharger, HVT oil, and turbo oil supply, the S1070 plays a key role. It ensures that all connections are sealed, preventing leaks and maintaining the efficiency of these systems.

Pressure Sensing Tube

In the pressure sensing tube system, the Grommet Seal ensures that connections are airtight. This is important for accurate pressure readings, which are essential for the proper functioning of the engine monitoring system.

Water Inlet Connection and Water Transfer Tube

For the water inlet connection and water transfer tube, the Grommet Seal ensures that water flows efficiently into and through the engine, contributing to effective cooling and preventing leaks.

Corrosion Resistor System

In corrosion resistor systems, the Grommet Seal helps in maintaining the integrity of fluid pathways, preventing leaks that could lead to corrosion and further damage to the engine components.

Turbocharger Oil Supply Tube

Finally, in the turbocharger oil supply tube, the Grommet Seal ensures that oil is delivered efficiently to the turbocharger, maintaining its lubrication and cooling, which is vital for its performance and longevity.

Conclusion

The S1070 Grommet Seal is a vital component in the maintenance and operation of commercial trucks, particularly within Cummins engines. Its role in preventing leaks, protecting cables and pipes, and ensuring the integrity of various engine systems underscores its importance in the commercial truck industry. Proper installation, regular maintenance, and timely replacement of this Cummins part are essential for the continued reliability and efficiency of truck operations.

SPECIFICATIONS

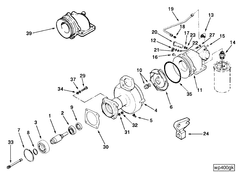

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.