Introduction

The Cummins 2872362 Position Sensor is a critical component designed to monitor and report the position of various parts within commercial trucks. It ensures the truck operates efficiently and safely by providing precise data on the position of critical components, contributing to the overall functionality and performance of the vehicle 1.

Basic Concepts of Position Sensors

Position sensors are devices that detect the position of an object and convert it into an electrical signal. These sensors are integral to many automotive systems, providing data that helps in the operation and control of various vehicle functions. They utilize different technologies such as magnetic, optical, or resistive methods to measure position 2. In automotive applications, position sensors are used for monitoring engine components, transmission systems, and steering mechanisms.

Purpose of the Cummins 2872362 Position Sensor

The Cummins 2872362 Position Sensor is specifically designed to monitor the position of components within a truck’s engine system. It plays a role in the engine’s control system by providing real-time data on the position of parts such as the throttle, which is crucial for optimizing engine performance. This sensor is integrated into the truck’s electronic control unit (ECU), allowing for precise adjustments and enhancements to the engine’s operation based on the data it provides 3.

Key Features

The Cummins 2872362 Position Sensor is characterized by its robust design and high-quality materials, which ensure durability and reliability in demanding truck environments. It incorporates advanced technological specifications that enhance its accuracy and responsiveness. The sensor is engineered to withstand the harsh conditions typical of commercial truck operations, ensuring consistent performance over time.

Benefits

The advantages of the Cummins 2872362 Position Sensor include improved engine efficiency and reliability. By providing accurate position data, it allows for more precise control of engine functions, which can lead to better fuel efficiency and reduced emissions. Additionally, the sensor contributes to enhanced safety by ensuring that engine components operate within their optimal ranges, reducing the risk of mechanical failures.

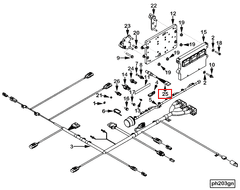

Installation and Integration

Installing the Cummins 2872362 Position Sensor involves connecting it to the appropriate components within the truck’s engine system and integrating it with the ECU. Proper installation requires following manufacturer guidelines to ensure accurate sensor placement and secure connections. This setup allows the sensor to effectively monitor and report position data, contributing to the truck’s overall performance.

Troubleshooting and Maintenance

Common issues with the Cummins 2872362 Position Sensor may include inaccurate readings or sensor failure. Diagnostic procedures involve checking the sensor’s connections, testing its output signal, and ensuring it is correctly integrated with the ECU. Regular maintenance, such as cleaning the sensor and its connections, can help prevent issues and ensure optimal performance. It is also important to monitor the sensor’s output for any signs of degradation or inconsistency.

Performance Impact

The Cummins 2872362 Position Sensor affects the overall performance of the truck by providing precise data that allows for optimized engine control. This can lead to improvements in fuel efficiency, emission control, and driver experience. The sensor’s accurate position reporting enables the ECU to make real-time adjustments, enhancing the truck’s responsiveness and efficiency.

Technological Advancements

The Cummins 2872362 Position Sensor incorporates several technological innovations that distinguish it from previous models and competing products. These advancements include improved accuracy, enhanced durability, and integration with modern ECU systems. The sensor’s design and materials are optimized for performance in commercial truck applications, ensuring it meets the demands of heavy-duty use.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established itself as a key player in the automotive industry, particularly in the development of components for commercial trucks. The company’s commitment to innovation and quality is evident in its product lineup, including the Cummins 2872362 Position Sensor.

Cummins Position Sensor 2872362 Compatibility

The Cummins Position Sensor part number 2872362 is designed to fit a variety of Cummins engines, ensuring precise engine operation and performance. Here are the engines that this sensor is compatible with:

B5.9 and C Series Engines

- B5.9 GAS PLUS CM556

- C GAS PLUS CM556

These engines benefit from the sensor’s ability to accurately measure the position of the engine’s components, ensuring smooth operation and optimal performance.

G Series Engines

- G5.9

- G5.9 CM558

- G8.3

- G8.3 CM558

- G855

- G855 CM558

- GTA8.3 CM558

- GTA855 CM558 (CM2358)

The G series engines, including both the G5.9 and G8.3 variants, rely on the 2872362 position sensor for precise timing and positioning data, which is crucial for maintaining engine efficiency and reliability.

ISM and QSK Series Engines

- ISM CM570

- QSK19 CM500

- QSK19G

- QSK60 G CM2358 K110

- QSK60G

- QSL9 G CM558

The ISM and QSK series engines, known for their robustness and power, use the 2872362 position sensor to ensure accurate engine positioning, which is vital for their high-performance applications.

KTA Series Engines

- KTA19GC

- KTA19GC CM558

KTA series engines, often used in heavy-duty applications, depend on the 2872362 position sensor to provide the necessary data for smooth and efficient engine operation.

L, M, and N Series Engines

- L10 CELECT

- M11 CELECT

- N14 CELECT PLUS

The L, M, and N series engines, which are part of the CELECT family, utilize the 2872362 position sensor to maintain precise engine control, ensuring optimal performance across various applications.

QSM Series Engines

- QSM11 CM570

The QSM11 CM570 engine, part of the QSM series, relies on the 2872362 position sensor for accurate positioning data, which is essential for its reliable and efficient operation.

Role of Part 2872362 Position Sensor in Engine Systems

The Part 2872362 Position Sensor is integral to the precise operation of various engine systems. It works in conjunction with the Ignition System to ensure that the spark timing is accurately controlled, enhancing combustion efficiency and reducing emissions.

In the Engine Control System, this sensor provides real-time data on the position of various components, allowing the Engine Control Module (ECM) to make necessary adjustments for optimal performance.

When integrated into an Assembly Kit, the Position Sensor ensures that all components are aligned correctly during installation, which is essential for the reliable operation of the engine.

The sensor also plays a significant role in the overall Arrangement of engine components, ensuring that each part functions within its designed parameters. This contributes to the durability and efficiency of the engine.

Finally, the data from the Position Sensor is vital for the Module to execute precise control over fuel injection timing and other critical functions, further enhancing the engine’s performance and reliability.

Conclusion

The Cummins 2872362 Position Sensor is a vital component in the efficient and safe operation of commercial trucks. Its precise monitoring and reporting of engine component positions contribute significantly to engine performance, fuel efficiency, and emissions control. The sensor’s robust design, advanced technological features, and compatibility with a wide range of Cummins engines make it an essential part of modern truck engine systems.

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.