This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

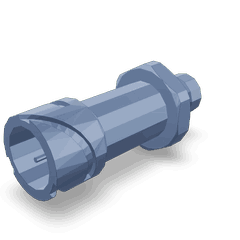

The Cummins 2987459 Pressure Sensor is a component designed to monitor and regulate pressure levels within commercial truck systems. Its purpose is to ensure optimal performance and efficiency of the truck’s engine and related systems. The significance of this sensor in commercial truck operations lies in its ability to provide accurate pressure readings, which are vital for maintaining the truck’s performance and reliability 1.

Basic Concepts of Pressure Sensors

Pressure sensors are devices that measure the force exerted by a fluid (liquid or gas) on a surface. They convert this physical pressure into an electrical signal, which can then be interpreted by the vehicle’s electronic systems. Pressure sensors are widely used in automotive systems to monitor and control various functions, such as fuel injection, brake systems, and engine management. Their role is to provide real-time data that helps in the efficient operation of these systems 2.

Role of the 2987459 Pressure Sensor in Truck Operation

The Cummins 2987459 Pressure Sensor plays a specific role in the operation of a commercial truck by monitoring the pressure within the engine’s fuel system. It ensures that the fuel is delivered at the correct pressure, which is crucial for the engine’s combustion process. The sensor is integrated within the truck’s systems to provide continuous feedback to the engine control unit (ECU), allowing for adjustments to be made in real-time to maintain optimal performance 3.

Key Features of the 2987459 Pressure Sensor

The Cummins 2987459 Pressure Sensor is characterized by several key features that enhance its performance and reliability. Its design incorporates high-quality materials that are resistant to the harsh conditions found in commercial truck environments. Technological specifications such as its precision in pressure measurement and durability under varying temperatures contribute to its effectiveness. These features ensure that the sensor can operate reliably over extended periods, providing accurate data to the truck’s systems.

Benefits of Using the 2987459 Pressure Sensor

Incorporating the Cummins 2987459 Pressure Sensor into truck systems offers several advantages. It contributes to improved engine efficiency by ensuring that fuel is delivered at the optimal pressure. This can lead to better fuel economy and reduced emissions. Additionally, the sensor enhances the reliability of the truck’s engine by providing accurate pressure readings that allow for timely adjustments and maintenance. Potential cost savings can be achieved through improved efficiency and reduced need for repairs due to engine malfunctions.

Installation and Integration

Proper installation and integration of the Cummins 2987459 Pressure Sensor within a truck’s system are important for its effective operation. Installation guidelines recommend ensuring that the sensor is correctly positioned within the fuel system to accurately measure pressure. It is also important to follow any prerequisites or considerations provided by the manufacturer to ensure compatibility with the truck’s existing systems. Careful integration helps in maintaining the sensor’s accuracy and reliability.

Maintenance and Troubleshooting

To ensure the longevity and optimal performance of the Cummins 2987459 Pressure Sensor, regular maintenance is recommended. This includes checking for any signs of wear or damage and ensuring that the sensor is clean and free from debris. Troubleshooting common issues may involve verifying the sensor’s connections and ensuring that it is receiving power. Addressing these aspects can help in maintaining the sensor’s functionality and accuracy over time.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established itself as a leader in diesel engine manufacturing, known for its commitment to innovation and quality. The company’s expertise in the automotive industry is demonstrated through its wide range of products designed to meet the demanding requirements of commercial and industrial applications.

Role of Part 2987459 Pressure Sensor in Engine Systems

The integration of Part 2987459 Pressure Sensor within engine systems is fundamental for maintaining optimal performance and efficiency. This sensor is instrumental in monitoring and regulating various parameters that are essential for the smooth operation of the engine.

Interaction with the Electronic Control Pressure Valve

The Pressure Sensor works in tandem with the Electronic Control Pressure Valve (ECPV). The sensor continuously measures the pressure within the system and sends this data to the ECPV. Based on the received information, the ECPV adjusts the pressure levels to ensure that they remain within the desired range. This dynamic interaction helps in maintaining consistent fuel delivery and combustion efficiency, which are vital for engine performance.

Communication with the Engine Control Module

The Pressure Sensor is a key component in the feedback loop involving the Engine Control Module (ECM). The sensor provides real-time pressure data to the ECM, which uses this information to make adjustments to various engine parameters. For instance, the ECM can modify the fuel injection timing or the air-fuel ratio based on the pressure readings. This ensures that the engine operates efficiently under varying conditions, whether it’s idling, cruising, or under heavy load.

Overall System Integration

In a broader context, the Pressure Sensor is part of a sophisticated network that includes various sensors and actuators. Its role is to provide accurate pressure readings that contribute to the overall management of the engine system. By ensuring that pressure levels are optimal, the sensor helps in reducing wear and tear on engine components, improving fuel economy, and minimizing emissions.

Conclusion

The seamless integration of Part 2987459 Pressure Sensor with the ECPV and ECM underscores its importance in modern engine systems. Its ability to provide precise data enables the engine to operate at peak efficiency, highlighting the sensor’s significant contribution to engine performance and reliability.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.