This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Fluid Level Sensor Housing, part number 3066437 by Cummins, is a component designed to facilitate the monitoring of fluid levels within commercial trucks. This part is integral to ensuring that the truck’s systems operate efficiently and reliably. By providing accurate fluid level readings, it helps maintain the optimal performance of the vehicle, contributing to its longevity and operational effectiveness.

Basic Concepts of Fluid Level Sensor Housing

A Fluid Level Sensor Housing is a protective enclosure that houses the fluid level sensor. This sensor is responsible for detecting the level of fluids such as oil, coolant, or fuel within the truck’s system. The housing protects the sensor from environmental factors and physical damage, ensuring consistent and accurate readings. It plays a role in the system by safeguarding the sensor and contributing to the overall reliability of fluid level monitoring.

Purpose and Role in Truck Operation

This Cummins part is specifically designed to enhance the monitoring of fluid levels in commercial trucks. Its purpose is to provide a durable and accurate housing solution for the fluid level sensor, ensuring that the sensor can operate under various conditions without degradation. This contributes to the truck’s operation by maintaining precise fluid levels, which is vital for engine performance, cooling system efficiency, and overall vehicle reliability.

Key Features

The Fluid Level Sensor Housing 3066437 boasts several key features that enhance its functionality and durability. It is constructed from high-quality materials that offer resistance to corrosion and physical impact. The design includes precise fitting mechanisms to ensure a secure attachment to the truck’s system, minimizing the risk of sensor displacement. Additionally, the housing is engineered to withstand extreme temperatures and environmental conditions commonly encountered in commercial trucking operations.

Benefits

Utilizing the Fluid Level Sensor Housing 3066437 offers several benefits. It provides improved accuracy in fluid level readings, which is crucial for maintaining optimal engine performance and preventing potential damage from fluid shortages. The durable construction of the housing enhances the longevity of the sensor, reducing the frequency of replacements and associated costs. Furthermore, the reliable performance of this part can lead to potential cost savings for fleet operators by minimizing downtime and maintenance expenses.

Installation Process

Installing the Fluid Level Sensor Housing 3066437 involves several steps to ensure proper integration into the truck’s system. Begin by identifying the correct location for the housing, typically near the fluid reservoir or sensor. Use the appropriate tools to remove the old housing, if applicable, and clean the area to ensure a secure fit. Position the new housing over the sensor and secure it in place using the provided fasteners. Finally, verify the installation by checking for proper sensor operation and secure attachment.

Troubleshooting Common Issues

Common issues with the Fluid Level Sensor Housing 3066437 may include inaccurate readings or sensor malfunctions. To address these, first, ensure that the housing is securely attached and that there are no obstructions affecting the sensor. Check for any signs of damage to the housing or sensor, and replace if necessary. Additionally, verify that the sensor is correctly calibrated and that the fluid levels are within the recommended range. Regular inspections and maintenance can help prevent these issues.

Maintenance Tips

To ensure the optimal performance and longevity of the Fluid Level Sensor Housing 3066437, regular maintenance is recommended. Inspect the housing for any signs of wear or damage during routine checks. Clean the exterior of the housing to remove any debris or contaminants that could affect sensor accuracy. Additionally, ensure that the sensor itself is functioning correctly and that fluid levels are maintained within the specified range. Following these practices will help sustain the reliability of the fluid level monitoring system.

Cummins Overview

Cummins Inc. is a renowned manufacturer with a long-standing reputation in the automotive industry. Founded in 1919, the company has built a legacy of producing high-quality components for commercial vehicles. Cummins is committed to innovation and excellence, consistently delivering reliable and efficient solutions for the trucking industry. Their components, including the Fluid Level Sensor Housing 3066437, are designed with precision and durability in mind, reflecting Cummins’ dedication to quality and performance.

Fluid Level Sensor Housing (Part 3066437) in Cummins Engines

The Fluid Level Sensor Housing, part number 3066437, is a critical component in several Cummins engine models. This part is designed to house the fluid level sensor, ensuring accurate monitoring of fluid levels within the engine system.

QSK19 CM500

In the QSK19 CM500 engine, the Fluid Level Sensor Housing is integral to maintaining optimal engine performance. The housing is strategically positioned to provide a reliable seal and protect the sensor from contaminants and environmental factors. This ensures that the sensor can accurately measure fluid levels, contributing to the engine’s overall efficiency and longevity.

Grouping of Engines

The Fluid Level Sensor Housing is compatible with a range of Cummins engines, including but not limited to, the QSK19 CM500. This part is engineered to fit seamlessly within the engine’s design, ensuring compatibility and ease of installation. The housing’s robust construction and precise fitment are critical for maintaining the integrity of the engine’s fluid monitoring system.

Role of Part 3066437 Fluid Level Sensor Housing in Engine Systems

The Fluid Level Sensor Housing (part 3066437) is an integral component in the accurate monitoring and management of fluid levels within various engine systems. Its primary function is to house and support the oil level sensor, ensuring precise measurements of the oil level within the engine.

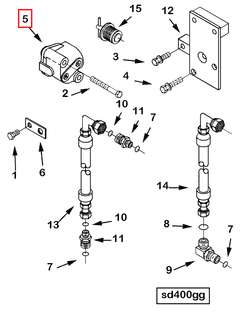

Integration with Oil Level Sensor

The housing provides a secure and stable environment for the oil level sensor. This sensor is responsible for detecting the current oil level and transmitting this data to the engine control unit (ECU). The housing ensures that the sensor is correctly positioned and protected from potential damage, thereby enhancing the reliability of the oil level readings.

Support Mounting

In addition to housing the sensor, the fluid level sensor housing also incorporates support mounting features. These features allow for the secure attachment of the housing to the engine block or sump. Proper mounting is essential for maintaining the sensor’s alignment and ensuring consistent performance. The support mounting also helps in dissipating any vibrations that could otherwise affect the sensor’s accuracy.

Overall Functionality

By integrating seamlessly with the oil level sensor and providing robust support mounting, the fluid level sensor housing plays a significant role in the overall functionality of the engine system. It ensures that the oil level is accurately monitored, which is vital for maintaining optimal engine performance and preventing potential damage due to incorrect oil levels.

Conclusion

The Fluid Level Sensor Housing 3066437 by Cummins is a critical component for ensuring the accurate monitoring of fluid levels in commercial trucks and engines. Its durable construction, precise fitting mechanisms, and compatibility with various Cummins engine models make it an essential part for maintaining optimal engine performance and reliability. Regular maintenance and proper installation are key to maximizing the benefits of this part, contributing to the longevity and efficiency of the vehicle’s fluid monitoring system.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.