This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3080406 Pressure Sensor is a component designed to monitor and regulate pressure levels within the systems of commercial trucks. Its purpose is to ensure that the truck operates efficiently and safely by providing accurate pressure readings to the truck’s control systems. This sensor is significant in maintaining the optimal performance of the vehicle, contributing to both engine efficiency and safety protocols 1.

Basic Concepts of Pressure Sensors

Pressure sensors are devices that measure the force exerted by a fluid (liquid or gas) on a surface. They convert this physical pressure into an electrical signal, which can then be interpreted by electronic systems. In automotive applications, pressure sensors play a role in monitoring various systems such as fuel injection, brake systems, and engine management. They help in maintaining the correct pressure levels, which is vital for the efficient operation of these systems 2.

Role of the 3080406 Pressure Sensor in Truck Operation

The Cummins 3080406 Pressure Sensor is integrated into the truck’s systems to monitor specific pressure points. It provides real-time data to the truck’s electronic control unit (ECU), allowing for adjustments to be made as necessary to maintain optimal performance. This sensor is particularly important in systems where precise pressure control is required, such as in the fuel system, where it helps ensure that the fuel is delivered at the correct pressure for efficient combustion 3.

Key Features of the 3080406 Pressure Sensor

The Cummins 3080406 Pressure Sensor is characterized by its robust design and high-quality construction materials, which enhance its durability and reliability. It incorporates advanced technological specifications that allow for accurate and consistent pressure readings. The sensor is designed to withstand the harsh conditions often encountered in commercial truck operations, ensuring long-term performance and reliability.

Benefits of Using the 3080406 Pressure Sensor

The use of the Cummins 3080406 Pressure Sensor is associated with several benefits. It contributes to improved engine performance by ensuring that systems operate at optimal pressure levels. This can lead to enhanced fuel efficiency, as the engine is able to combust fuel more effectively. Additionally, the sensor plays a role in increasing safety by providing precise pressure monitoring, which helps prevent system failures and ensures that the truck operates within safe parameters.

Installation and Integration

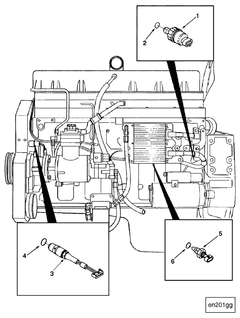

Proper installation and integration of the Cummins 3080406 Pressure Sensor into a truck’s system are important for ensuring its effective operation. This process involves several preparatory steps, including ensuring that the sensor is compatible with the truck’s systems and that it is installed in the correct location. Careful attention to these details helps ensure that the sensor functions as intended and provides accurate pressure readings.

Troubleshooting Common Issues

Common issues that may arise with the Cummins 3080406 Pressure Sensor include inaccurate readings, sensor failure, and integration problems. Troubleshooting these issues involves a systematic approach to diagnosing the problem, which may include checking the sensor’s connections, testing its output, and ensuring that it is correctly integrated into the truck’s systems. Addressing these issues promptly helps maintain the sensor’s performance and the truck’s overall efficiency.

Maintenance Tips

Regular maintenance of the Cummins 3080406 Pressure Sensor is important for ensuring its longevity and optimal performance. This includes cleaning the sensor to remove any contaminants that may affect its readings, inspecting it for signs of wear or damage, and calibrating it as necessary to ensure accurate pressure readings. Following these maintenance tips helps ensure that the sensor continues to function effectively over time.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins has established itself as a leader in the diesel engine manufacturing industry. The company’s commitment to excellence is evident in its products, including the Cummins 3080406 Pressure Sensor, which is designed to meet the demanding requirements of commercial truck operations.

Pressure Sensor 3080406 Compatibility with Cummins Engines

The Pressure Sensor 3080406, manufactured by Cummins, is a critical component designed to fit seamlessly with a variety of Cummins engines. This sensor is engineered to ensure optimal performance and reliability across different engine models. Below is a detailed overview of the compatibility of this pressure sensor with various Cummins engines.

ISB CM550 Series

The Pressure Sensor 3080406 is compatible with the ISB CM550 engine, ensuring precise pressure readings that are crucial for maintaining engine efficiency and performance.

ISC CM554 Series

This pressure sensor fits the ISC CM554 engine, providing accurate pressure data that aids in the engine’s operational efficiency and longevity.

ISL CM554 Series

The ISL CM554 engine is another model that benefits from the 3080406 pressure sensor, ensuring that pressure readings are accurate and reliable.

ISM CM570 Series

The ISM CM570 engine is designed to work with the 3080406 pressure sensor, which is essential for maintaining the engine’s performance and ensuring it operates within safe pressure limits.

K38 and K50 Series

Both the K38 and K50 engines are compatible with the 3080406 pressure sensor, providing the necessary pressure data to keep these engines running smoothly.

KTA19GC CM558 Series

The KTA19GC CM558 engine is another model that can utilize the 3080406 pressure sensor, ensuring that it operates at optimal pressure levels.

L10 CELECT Series

The L10 CELECT engine is compatible with the 3080406 pressure sensor, ensuring that it receives accurate pressure readings for optimal performance.

M11 CELECT and M11 CELECT PLUS Series

Both the M11 CELECT and M11 CELECT PLUS engines are designed to work with the 3080406 pressure sensor, ensuring that they operate within safe pressure parameters.

N14 CELECT PLUS Series

The N14 CELECT PLUS engine is compatible with the 3080406 pressure sensor, providing the necessary pressure data to maintain engine efficiency and performance.

QSB5.9 44 CM550 Series

The QSB5.9 44 CM550 engine is another model that can utilize the 3080406 pressure sensor, ensuring that it operates at optimal pressure levels.

QSC8.3 CM554 Series

The QSC8.3 CM554 engine is compatible with the 3080406 pressure sensor, providing accurate pressure readings that are crucial for maintaining engine efficiency.

QSK19 CM500 and QSK19 CM850 MCRS Series

Both the QSK19 CM500 and QSK19 CM850 MCRS engines are designed to work with the 3080406 pressure sensor, ensuring that they operate within safe pressure limits.

QSK19G and QSM11 CM570 Series

The QSK19G and QSM11 CM570 engines are compatible with the 3080406 pressure sensor, providing the necessary pressure data to maintain engine efficiency and performance.

Role of Part 3080406 Pressure Sensor in Engine Systems

The part 3080406 Pressure Sensor is an integral component within various engine systems, providing essential data that contributes to the overall performance and efficiency of the engine.

Coolant Pressure Sensor Integration

When integrated with the coolant pressure sensor, the 3080406 Pressure Sensor monitors the pressure within the coolant system. This data is vital for maintaining optimal engine temperature, ensuring that the engine operates within safe parameters and preventing overheating.

Electronic Engine Monitor and Engine Monitoring System

In conjunction with the electronic engine monitor and engine monitoring system, the 3080406 Pressure Sensor delivers real-time pressure readings. These systems utilize the sensor’s data to provide comprehensive engine diagnostics, allowing for proactive maintenance and timely interventions.

Electronic Service Calibration

During electronic service calibration, the 3080406 Pressure Sensor plays a key role by providing accurate pressure measurements. This ensures that the calibration process is precise, leading to improved engine performance and reliability post-service.

Engine Control Module (ECM) and ECM Plumbing

The 3080406 Pressure Sensor communicates directly with the Engine Control Module (ECM) through the ECM plumbing. The sensor’s data helps the ECM make informed decisions regarding fuel injection, ignition timing, and other critical engine functions, thereby enhancing overall engine efficiency.

Engine Instrument and Lubricating Oil Filter

When paired with engine instruments and the lubricating oil filter, the 3080406 Pressure Sensor monitors oil pressure within the engine. This is essential for ensuring that the lubrication system is functioning correctly, which is paramount for reducing wear and tear on engine components.

Lubricating Oil Filter Head

The sensor also works in tandem with the lubricating oil filter head to provide continuous monitoring of oil pressure. This ensures that the filter head is operating within specified parameters, contributing to the longevity and performance of the engine.

CensE Upfit Kit

In CensE upfit kits, the 3080406 Pressure Sensor is often included to enhance the engine’s monitoring capabilities. The sensor’s data is used to fine-tune the engine’s performance, making it an invaluable component in upfit applications where precision is key.

Conclusion

In summary, the 3080406 Pressure Sensor is a versatile and essential component across various engine systems, providing accurate pressure data that is utilized by multiple subsystems to ensure optimal engine performance and reliability.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.